Quick-bonding UV/moisture dual-curing adhesive and preparation method thereof

A dual-curing, adhesive technology, used in adhesives, adhesive types, adhesive additives, etc., can solve the problem that two-component structural adhesives and PUR hot-melt adhesives cannot achieve instant bonding and positioning, double-sided adhesive Insufficient relay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Synthesis of UV / Moisture Dual Curing Urethane Acrylic Resin

[0025] 50.0 parts of PPG-2000 (polyether diol, Dow, USA) were dehydrated under vacuum at 110°C for 2 hours, and the temperature was lowered to 70°C. Added 30 parts of polymeric MDI (8319, Yantai Wanhua), 0.01 parts of Butyl tin, reacted for 2 hours. Add 2.0 parts of hydroxyethylacrylamide and continue the reaction for 2 hours. After vacuum defoaming for 0.5 hour, a UV / moisture dual-curing polyurethane acrylic resin (named as resin 1) was obtained.

Embodiment 2

[0026] Example 2: Synthesis of UV / Moisture Dual Curing Urethane Acrylic Resin

[0027] 56.0 parts of PCL220 (polycaprolactone diol, Daicel Corporation, Japan) were vacuum dehydrated at 110°C for 2 hours, the temperature was lowered to 70°C, 40 parts of polymeric MDI (8319, Yantai Wanhua), 0.01 parts of dilauric acid di Butyl tin, reacted for 2 hours. 4.0 parts of hydroxyethylacrylamide was added, and the reaction was continued for 2 hours. After vacuum defoaming for 0.5 hour, a UV / moisture dual-curing polyurethane acrylic resin (named as resin 2) was obtained.

Embodiment 3

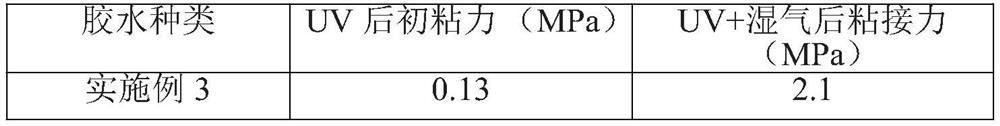

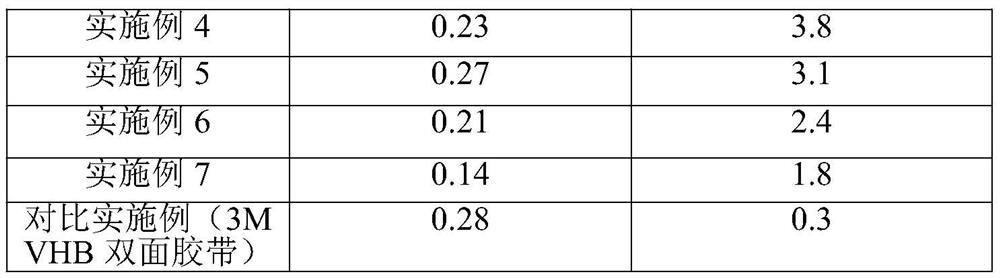

[0031] Mix the following compounds uniformly under vacuum conditions: 30.0 g of monofunctional urethane acrylic resin (GENOMER*4188, RAHN company), 15.0 g of UV / moisture dual curing urethane acrylic resin (self-made resin 1), 4.5 g of isooctyl acrylate , fumed silica (TS720, Cabot Corporation) 1.0 g, photoinitiator (ethyl 2,4,6-trimethylbenzoylphenylphosphonate) 1.5 g, dibutyltin dilaurate 0.01 g. Apply the mixed raw materials on the glass sample strip, use LED lamp (365nm, curing energy is 2000mJ / cm 2 ) after irradiation, attach the glass sample strips to test the initial adhesive force and the adhesive force after moisture curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com