UV two-component dual-cure structural adhesive

A dual-curing, structural adhesive technology, used in adhesives, organic chemistry, adhesive types, etc., can solve the problems of UV glue shadows that cannot be cured, uncontrollable curing speed, etc., to achieve good optical transparency and refractive index, good adhesion. Bond strength, good structural strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

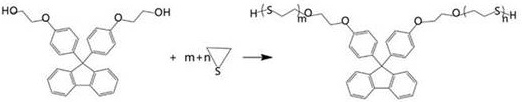

[0034] (1) Synthesis of bisphenol fluorene polyether polythiol with bisphenol fluorene structure

[0035] Add 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, basic catalyst and solvent A into the reaction kettle, and raise the reaction temperature to 50°C. After 1 hour of reaction Bisphenol fluorene polyether polythiol with bisphenol fluorene structure can be obtained, wherein the quality of 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, basic catalyst and solvent A The ratio is 1:0.1:0.01:5; the chemical reaction equation is shown in the figure below:

[0036]

[0037] Among them, m+n=4;

[0038] The basic catalyst is triethylamine, and the solvent A is formamide.

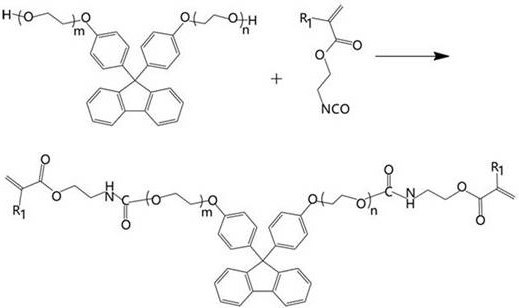

[0039] (2) Bisphenol fluorene polyether polyol with acrylic structure

[0040] Dissolve bisphenol fluorene polyether polyol in solvent A, then add acrylate structure monomer with isocyano group, raise the reaction temperature to 40°C, react for 1 hour, and obtain acrylic acid with ac...

Embodiment 2

[0050] (1) Synthesis of bisphenol fluorene polyether polythiol with bisphenol fluorene structure

[0051] Add 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, basic catalyst and solvent A into the reaction kettle, the reaction temperature is raised to 100°C, and after 5 hours of reaction Bisphenol fluorene polyether polythiol with bisphenol fluorene structure can be obtained, wherein the quality of 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, basic catalyst and solvent A The ratio is 1:10:0.5:50; the chemical reaction equation is shown in the figure below:

[0052]

[0053] Among them, m+n=20;

[0054] The basic catalyst is sodium hydroxide, and the solvent A is dimethylsulfoxide.

[0055] (2) Bisphenol fluorene polyether polyol with acrylic structure

[0056] Dissolve bisphenol fluorene polyether polyol in solvent A, then add acrylate structure monomer with isocyano group, raise the reaction temperature to 80°C, react for 3 hours, and obtain ac...

Embodiment 3

[0066] (1) Synthesis of bisphenol fluorene polyether polythiol with bisphenol fluorene structure

[0067] Add 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, and basic catalyst coating solvent A into the reaction kettle, and the reaction temperature is raised to 80°C. After 4 hours of reaction Bisphenol fluorene polyether polythiol with bisphenol fluorene structure can be obtained, wherein the quality of 9,9 bis[6-(2-hydroxyethoxy)phenyl]fluorene, ethylene oxide, basic catalyst and solvent A The ratio is 1:6:0.4:20; the chemical reaction equation is shown in the figure below:

[0068]

[0069] Among them, m+n=15;

[0070] Wherein the basic catalyst is potassium carbonate, and the solvent A is dioxane.

[0071] (2) Bisphenol fluorene polyether polyol with acrylic structure

[0072] Dissolve bisphenol fluorene polyether polyol in solvent A, then add acrylate structure monomer with isocyano group, raise the reaction temperature to 60°C, react for 2 hours, and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com