Double-layer structural skin wound dressing based on polysiloxane supra-molecular elastomers and preparation method of skin wound dressing

A supramolecular elastomer and polysiloxane technology, applied in the field of synthetic polymer biomaterials, can solve the problems of aggravating the pain of patients and increasing the workload of nursing, and achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

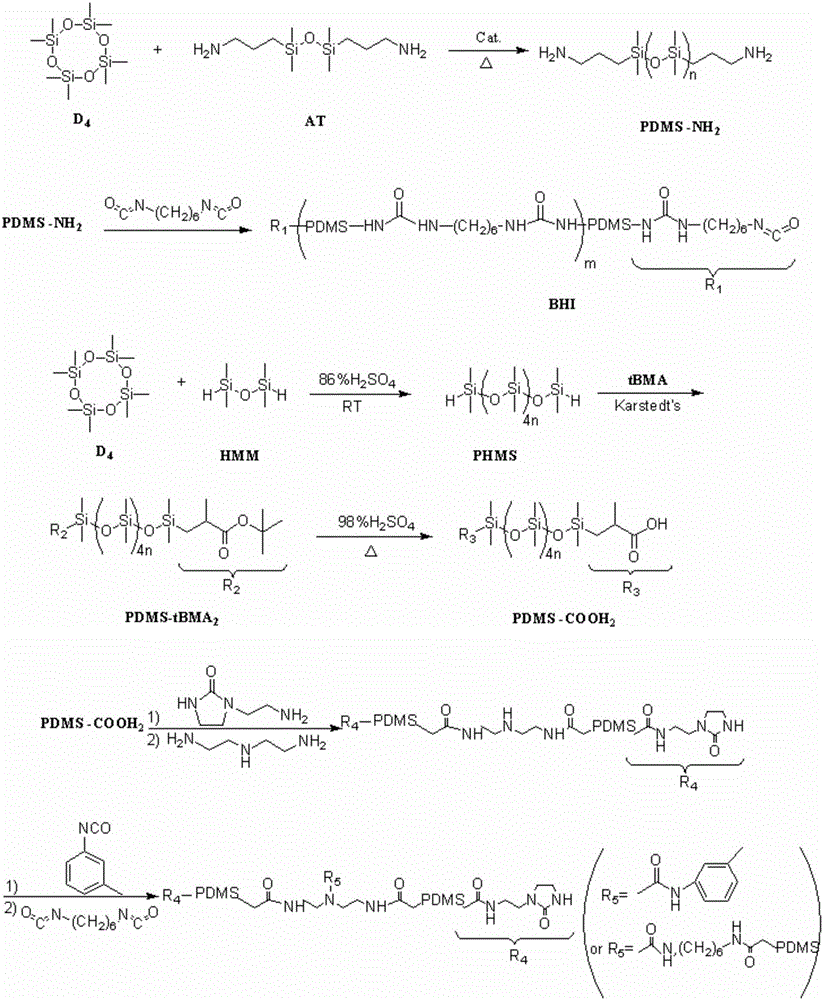

Method used

Image

Examples

Embodiment 1

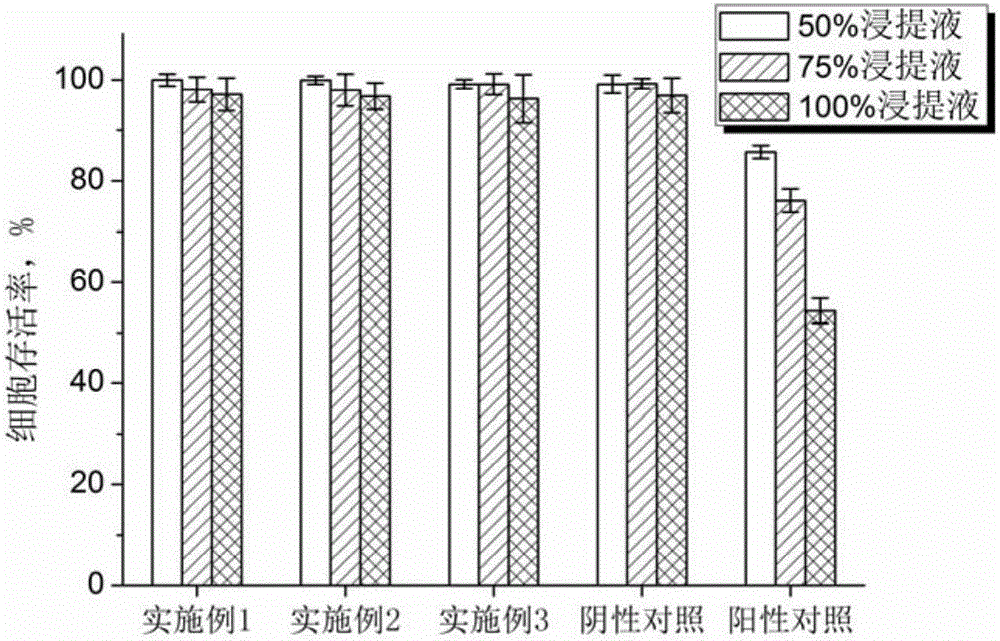

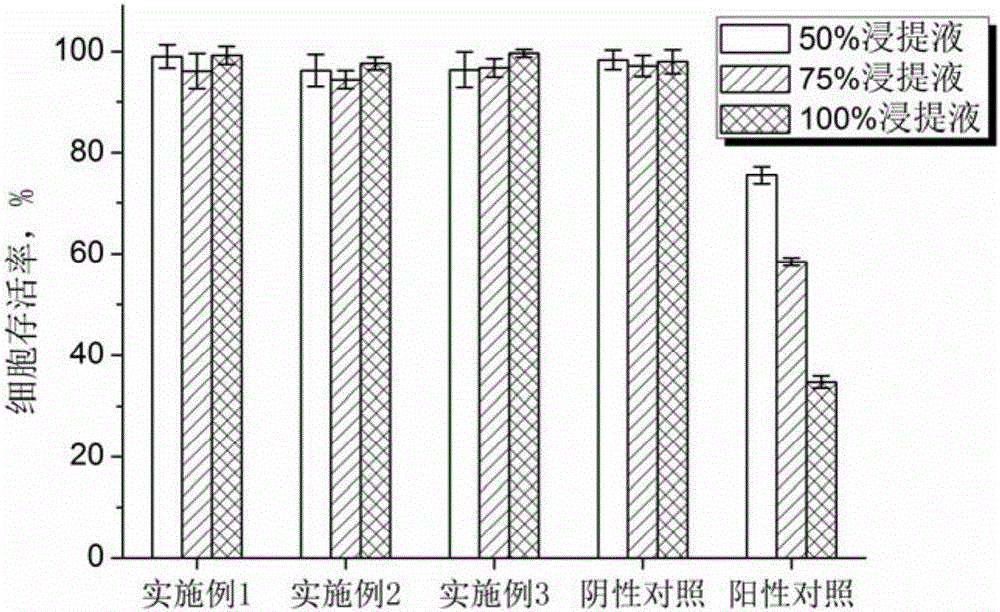

[0072] Embodiment 1: a kind of skin wound dressing (HSE) with bilayer structure based on polysiloxane supramolecular elastomer 2027 / 3500 ) preparation

[0073] (1) Amino-terminated polysiloxane (PDMS-NH 2 ) of synthetic: in the reactor that is equipped with mechanical stirring, condensation pipe, by raw material molar ratio is AT:D 4 =1:6 feeding (0.14mol AT and 0.84mol D 4 ), adding the equivalent of D 4 The concentration of 0.5% by mass is 25wt% tetramethylammonium hydroxide ethanol solution. Reaction at 80°C for 9h. After the reaction, the temperature of the oil bath was raised to 150° C. and heated for 1 h to remove the catalyst. After the crude product was cooled to room temperature, it was distilled under reduced pressure at 150°C to remove residual D 4 You can get PDMS-NH 2 .

[0074] (2) Synthesis of flexible substrate layer supramolecular elastomer (BHI): at room temperature, add PDMS-NH 2 , and with equivalent PDMS-NH 2 Two times the mass of chloroform was ...

Embodiment 2

[0083] Embodiment 2: a kind of skin wound dressing (HSE) with bilayer structure based on polysiloxane supramolecular elastomer 3272 / 3500 ) preparation

[0084] (1) Amino-terminated polysiloxane (PDMS-NH 2 ) of synthetic: in the reactor that is equipped with mechanical stirring, condensation pipe, by raw material molar ratio is AT:D 4 =1:12 feeding (0.07mol AT and 0.84mol D 4 ), adding the equivalent of D 4The concentration of 1% by mass is 25wt% tetramethylammonium hydroxide ethanol solution. Reaction at 80°C for 9h. After the reaction, the temperature of the oil bath was raised to 150° C. and heated for 1 h to remove the catalyst. After the crude product was cooled to room temperature, it was distilled under reduced pressure at 150°C to remove residual D 4 You can get PDMS-NH 2 .

[0085] (2) Synthesis of flexible substrate layer supramolecular elastomer (BHI): at room temperature, add PDMS-NH 2 , and with equivalent PDMS-NH 2 Two times the mass of chloroform was di...

Embodiment 3

[0094] Embodiment 3: a kind of skin wound dressing (HSE) with double-layer structure based on polysiloxane supramolecular elastomer 5883 / 3500 ) preparation

[0095] (1) Amino-terminated polysiloxane (PDMS-NH 2 ) of synthetic: in the reactor that is equipped with mechanical stirring, condensation pipe, by raw material molar ratio is AT:D 4 =1:19 feeding (0.044mol AT and 0.84mol D 4 ), adding the equivalent of D 4 The concentration of mass 2% is 25wt% tetramethylammonium hydroxide ethanol solution. Reaction at 80°C for 9h. After the reaction, the temperature of the oil bath was raised to 150° C. and heated for 1 h to remove the catalyst. After the crude product was cooled to room temperature, it was distilled under reduced pressure at 150°C to remove residual D 4 You can get PDMS-NH 2 .

[0096] (2) Synthesis of flexible substrate layer supramolecular elastomer (BHI): at room temperature, add PDMS-NH 2 , and with equivalent PDMS-NH 2 Three times the mass of chloroform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com