A kind of optical grade self-adhesive polyethylene protective film and preparation method thereof

A polyethylene protective film, self-adhesive technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem that the protective film cannot achieve optical grade transparency, damage to electronic components, and peeling force of the protective film. problems such as lowering, to achieve the effects of excellent self-adhesion, easy processing and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

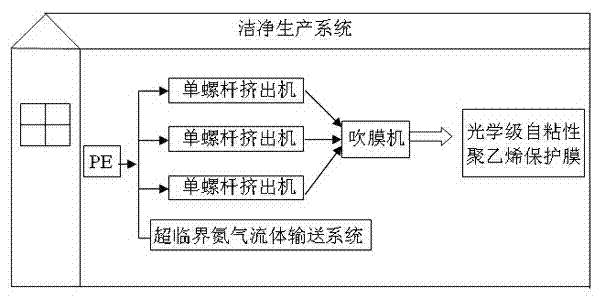

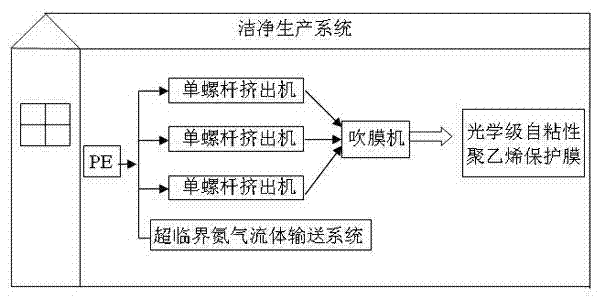

Method used

Image

Examples

Embodiment 1

[0022] Low-density polyethylene 2420H produced by Daqing Petrochemical is used as the back layer resin of the protective film; 30 parts of low-density polyethylene 2420H produced by Daqing Petrochemical is taken, and 70 parts of medium-density polyethylene 3505CH produced by Exxon Mobil is used as the middle layer of the protective film Layer resin; get 30 parts of low-density polyethylene 2420H produced by Daqing Petrochemical, and 70 parts of metallocene low-density polyethylene 1018HA produced by Exxon Mobil as the self-adhesive layer resin of the protective film.

[0023] The three-layer resin is co-extruded through three extruders. When extruding, a supercritical nitrogen fluid delivery system is used. The three machines are all heated in 5 stages. The temperature of the 5 stages from the head to the feed port is set to: 195 ℃, 180℃, 175℃, 160℃, 110℃. After extrusion, the film is blown to obtain a three-layer composite protective film. The process of extrusion blown film ...

Embodiment 2

[0026] Low-density polyethylene 2420H produced by Yangzi BASF is used as the back layer resin of the protective film; 30 parts of low-density polyethylene 2420H produced by Yangzi BASF and 70 parts of medium-density polyethylene 3505CH produced by ExxonMobil are used as the middle layer of the protective film Layer resin; get 30 parts of low-density polyethylene 2420H produced by Yangzi BASF, and 70 parts of metallocene low-density polyethylene 1018HA produced by Exxon Mobil as the self-adhesive layer resin of the protective film.

[0027] The three-layer resin is co-extruded through three extruders. When extruding, a supercritical nitrogen fluid delivery system is used. The three machines are all heated in 5 stages. The temperature of the 5 stages from the head to the feed port is set to: 195 ℃, 180℃, 175℃, 160℃, 110℃. After extrusion, the film is blown to obtain a three-layer composite protective film. The process of extrusion blown film is carried out in a dust-free and cle...

Embodiment 3

[0030] Low-density polyethylene 410E produced by Dow Chemical is used as the back layer resin of the protective film; 30 parts of low-density polyethylene 100BW produced by Exxon Mobil and 70 parts of medium-density polyethylene 6910AA produced by BP are used as the middle layer of the protective film. Layer resin; get 30 parts of low-density polyethylene 410E produced by Dow Chemical, and 70 parts of metallocene low-density polyethylene 1318CA produced by Exxon Mobil as the self-adhesive layer resin of the protective film.

[0031] The three-layer resin is co-extruded through three extruders. Supercritical nitrogen fluid delivery system technology is used for extrusion. The three machines are all heated in 5 stages, and the temperature of the 5 stages from the head to the feed port is set to: 190 ℃, 180℃, 170℃, 155℃, 100℃. After extrusion, the film is blown to obtain a three-layer composite protective film. The process of extrusion blown film is carried out in a dust-free and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com