301 stainless steel production method, and 301 stainless steel and application thereof

A production method and stainless steel technology, applied in the production method of 301 stainless steel and the field of 301 stainless steel, can solve the problems of poor corrosion resistance, failure to meet the manufacturing requirements of high-end elastic components, and poor corrosion resistance, so as to improve hardenability and creep Effects of improving performance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for producing 301Si stainless steel. The 301Si stainless steel includes the following chemical components in terms of weight percentage: C: 0.1113; Si: 1.246; Mn: 1.365; P: 0.034; S: 0.0016; Cr16.374; Ni: 6.3; N : 0.0146; Mo: 0.107, the balance is Fe and other unavoidable impurity elements; Md30 is 23 ~ 65 ° C; it is characterized by the following steps:

[0050] 1) Smelting of billets:

[0051] The steel billet is dissolved by the electric furnace, and then decarburized by the converter argon oxygen decarburization (AOD) furnace, and the molten steel is further purified through the reduction stage, and high-quality raw materials are added at the end of blowing to adjust the composition. Continue to carry out argon blowing (element symbol Ar) stirring in the refining furnace (LT) of the ladle treatment process to make the inclusions in the molten steel float up, and absorb the floating inclusions through the covering agent that has been put in. During the ladle...

Embodiment 2

[0062] A method for producing 301SiMo stainless steel. The 301SiMo stainless steel includes the following chemical components in terms of weight percentage: C: 0.1102; Si: 1.241; Mn: 1.332; P: 0.0309; S: 0.0018; Cr: 16.309; Ni: 6.57; : 0.0157; Mo: 0.577, the balance is Fe and other unavoidable impurity elements, Md30 is 11 ~ 53 ℃; it is characterized by the following steps:

[0063] 1) Smelting of billets:

[0064] The steel billet is dissolved by the electric furnace, and then decarburized by the converter argon oxygen decarburization (AOD) furnace, and the molten steel is further purified through the reduction stage, and high-quality raw materials are added at the end of blowing to adjust the composition. Continue to carry out argon blowing (element symbol Ar) stirring in the refining furnace (LT) of the ladle treatment process to make the inclusions in the molten steel float up, and absorb the floating inclusions through the covering agent that has been put in. During the l...

Embodiment 3

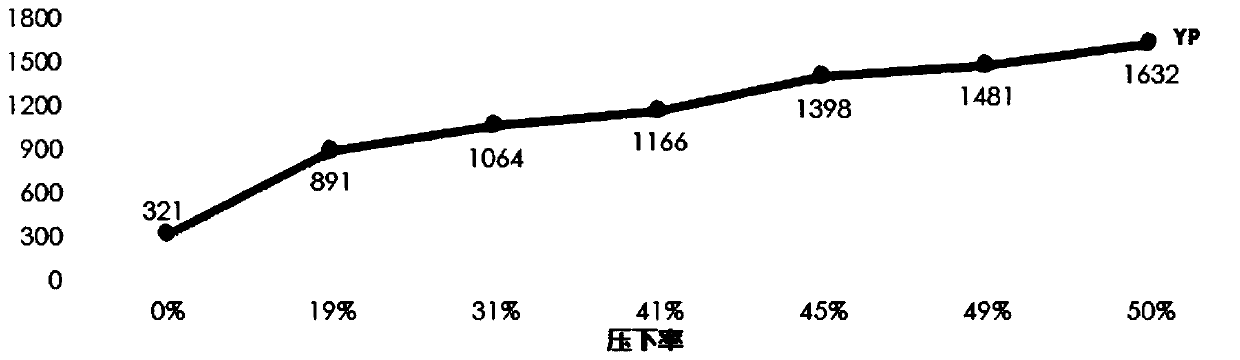

[0082] The 301SiMo stainless steel obtained in Example 2 is used in the fields of high-end elastic components, electronic equipment, etc., and undergoes precision rolling and tempering treatment during use. Such as image 3 Shown is the variation curve of the processing strength of 301SiMo stainless steel, and it can be seen that the reduction rate is linearly related to the processing strength (Yp).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com