Single-component asphalt-based water-based non-cured rubber asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating, non-curing rubber technology, applied in the direction of asphalt coating, chloroprene homopolymer coating, coating, etc., can solve the problems of harmful volatile substances, damage to human health, complex construction process, etc., and achieve storage Excellent stability, saving construction cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

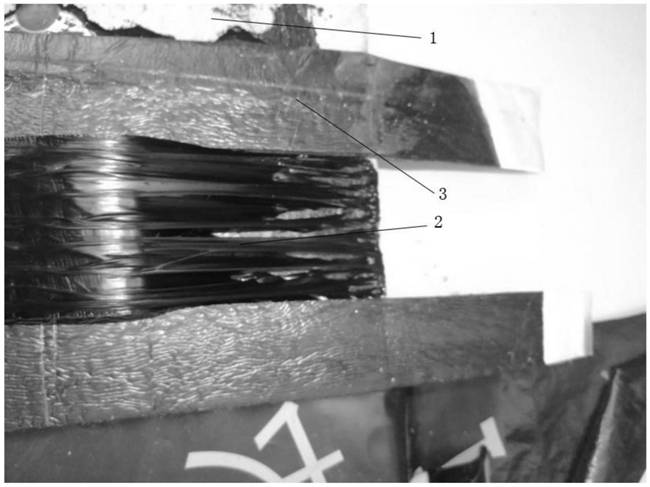

Image

Examples

Embodiment 1

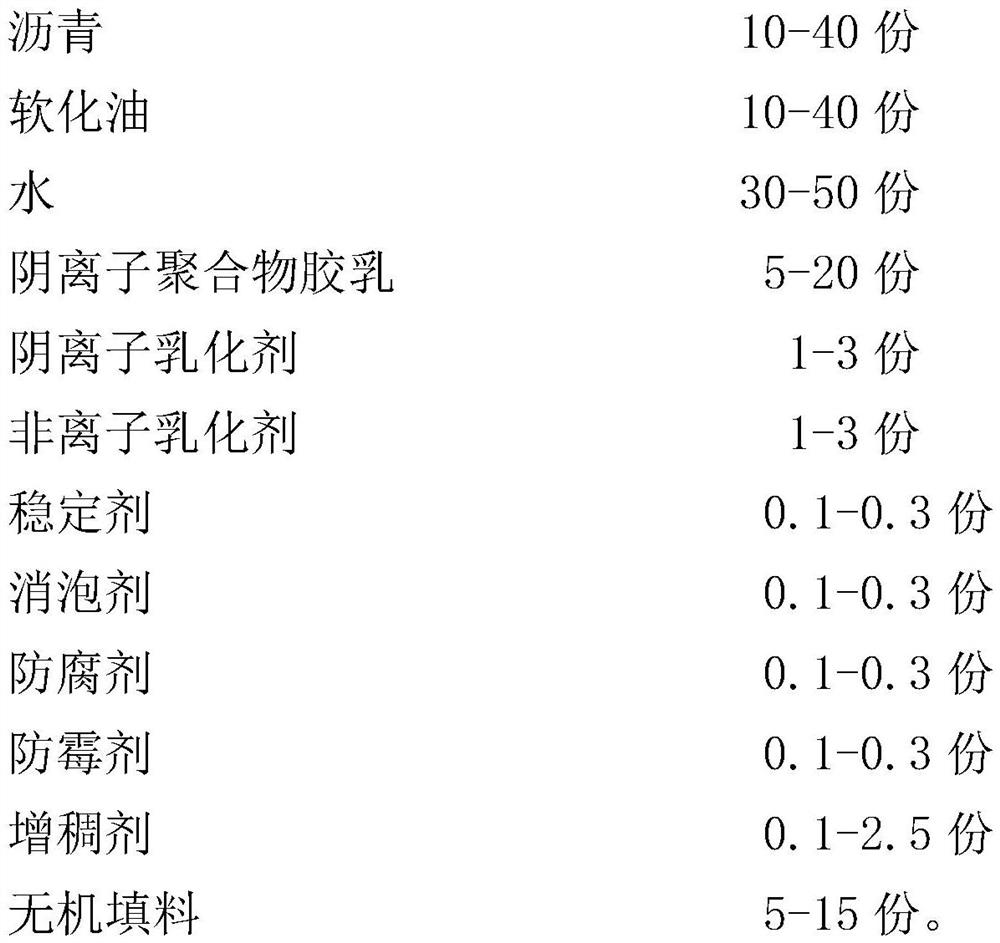

[0054] A one-component asphalt-based water-based non-curing rubber asphalt waterproof coating according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0055]

[0056] The preparation method of described one-component asphalt-based water-based non-curing rubber asphalt waterproof coating comprises the following steps carried out in sequence:

[0057] 1) Weigh each raw material respectively according to the weight and number ratio, then add carboxylate emulsifier, long-chain fatty alcohol polyoxyethylene ether and carboxymethyl cellulose sodium into distilled water and mix well, and prepare soap liquid, Then adjust the pH value of the soap solution to 11;

[0058] 2) Mix 30# asphalt with white oil, heat to 135°C, and stir for 0.8 hours to obtain modified asphalt;

[0059] 3) Mixing and grinding the soap solution obtained in step 1) and the modified asphalt obtained in step 2) for 2 min throu...

Embodiment 2

[0064] A one-component asphalt-based water-based non-curing rubber asphalt waterproof coating according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0065]

[0066] The preparation method of described one-component asphalt-based water-based non-curing rubber asphalt waterproof coating comprises the following steps carried out in sequence:

[0067] 1) Weigh each raw material respectively according to the weight and part ratio, then add the sulfonate emulsifier, alkylphenol polyoxyethylene ether and hydroxyethyl cellulose into deionized water and mix well, and prepare soap liquid, then Adjust the pH of the soap to 10;

[0068] 2) Mix 50# asphalt with white oil, heat to 140°C, and stir for 0.5 hours to obtain modified asphalt;

[0069] 3) Mixing and grinding the soap solution obtained in step 1) and the modified asphalt obtained in step 2) for 3 minutes through a colloid mill to prepare emu...

Embodiment 3

[0074] A one-component asphalt-based water-based non-curing rubber asphalt waterproof coating according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0075]

[0076] The preparation method of described one-component asphalt-based water-based non-curing rubber asphalt waterproof coating comprises the following steps carried out in sequence:

[0077] 1) Weigh each raw material respectively according to the weight and number ratio, then add sulfate ester emulsifier, fatty acid polyoxyethylene ester and hydroxypropyl methylcellulose into tap water and mix well, and prepare soap liquid, then add The pH value of the soap is adjusted to 12;

[0078] 2) Mix 70# asphalt with lubricating oil, heat to 130-140°C, and stir for 1 hour to obtain modified asphalt;

[0079] 3) mixing and grinding the soap solution obtained in step 1) and the modified asphalt obtained in step 2) through a colloid mill for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com