Composite emulsified asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating and emulsified asphalt technology, which is applied in the direction of asphalt coating, natural rubber coating, chloroprene homopolymer coating, etc. It can solve the problems of poor dispersion of fillers, film thickness of waterproof coating, unsatisfactory coating film quality, difficult Adapt to the harsh environment and climate, etc., to achieve the effect of fine paint, no defects in the coating film, and improved viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

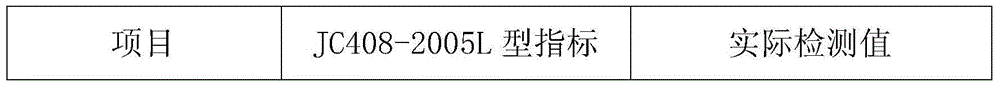

Embodiment 1

[0033] Mix 30 parts of water, 6 parts of dispersant, 3 parts of wetting agent, 2 parts of stabilizer, 70 parts of inorganic powder, and 2 parts of defoaming agent. The special dispersing machine with a toothed dispersing disc has a rotating speed of 2000r / min and a high speed Stir for 40 minutes; then add 220 parts of emulsified asphalt, a special disperser with a toothed dispersing disc at a speed of 500r / min, and stir for 10 minutes at a slow speed; then add 60 parts of polymer emulsion, a special dispersing machine with a toothed dispersing disc Stir at a slow speed of 500r / min for 10 minutes; then add 1.5 parts of thickener I, and stir for 10 minutes at a speed of 500r / min with a special disperser with a toothed dispersing disc; finally add thickener II 3 parts, a special dispersing machine with a toothed dispersing disc at a speed of 500r / min, stirring at a slow speed for 15 minutes; after that, the material is discharged, and the organic / inorganic composite water-emulsion...

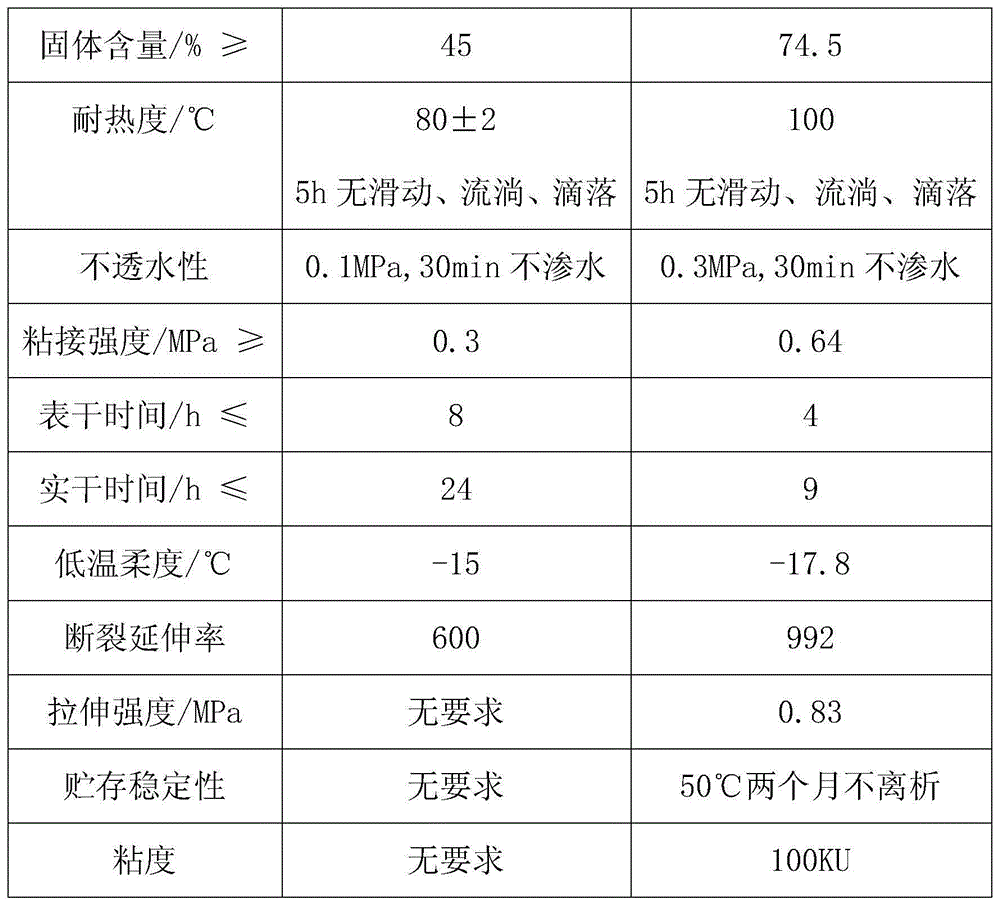

Embodiment 2

[0038] Mix 15 parts of water, 8 parts of dispersant, 5 parts of wetting agent, 2 parts of stabilizer, 77 parts of inorganic powder, and 2.5 parts of defoaming agent. The special dispersing machine with a toothed dispersing disc has a rotating speed of 1500r / min and a high speed Stir for 40 minutes; then add 150 parts of emulsified asphalt, a special disperser with a toothed dispersing disc at a speed of 100r / min, and stir for 10 minutes at a slow speed; then add 80 parts of polymer emulsion, a special dispersing machine with a toothed dispersing disc Stir at a slow speed of 10 minutes at a speed of 100r / min; then add 1.5 parts of thickener I, and stir for 10 minutes at a speed of 100r / min with a special disperser with a toothed dispersing disc; finally add thickener II 3 parts, a special dispersing machine with a toothed dispersing disc at a speed of 100r / min, stirring at a slow speed for 15 minutes; after that, the material is discharged, and the organic / inorganic composite wa...

Embodiment 3

[0042]Mix 40 parts of water, 10 parts of dispersant, 2 parts of wetting agent, 0.5 parts of stabilizer, 130 parts of inorganic powder, and 7 parts of defoaming agent. The special dispersing machine with toothed dispersing disc is set at a speed of 2000r / min and high speed Stir for 30 minutes; then add 200 parts of emulsified asphalt, a special disperser with a toothed dispersing disc at a speed of 500r / min, and stir for 5 minutes at a slow speed; then add 105 parts of polymer emulsion, a special dispersing machine with a toothed dispersing disc Stir at a slow speed of 5 minutes at a speed of 500r / min; then add 1 part of thickener I, and use a special disperser with a toothed dispersing disc at a speed of 500r / min, stir at a slow speed for 5 minutes; finally add thickener II 1 part, a special disperser with a toothed dispersing disc, at a speed of 500r / min, stir for 5 minutes at a slow speed; after that, the material is discharged, and the organic / inorganic composite water-emuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com