High-polymer modified water-emulsion asphalt-based thick waterproof paint and preparation method thereof

A technology of polymer modified and waterproof coatings, applied in asphalt coatings, chloroprene homopolymer coatings, cellulose coatings, etc., can solve the problems of poor coating stability, poor compatibility, affecting the water resistance of coating films, etc. , to achieve the effect of improving weather resistance, improving viscosity and plasticity, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

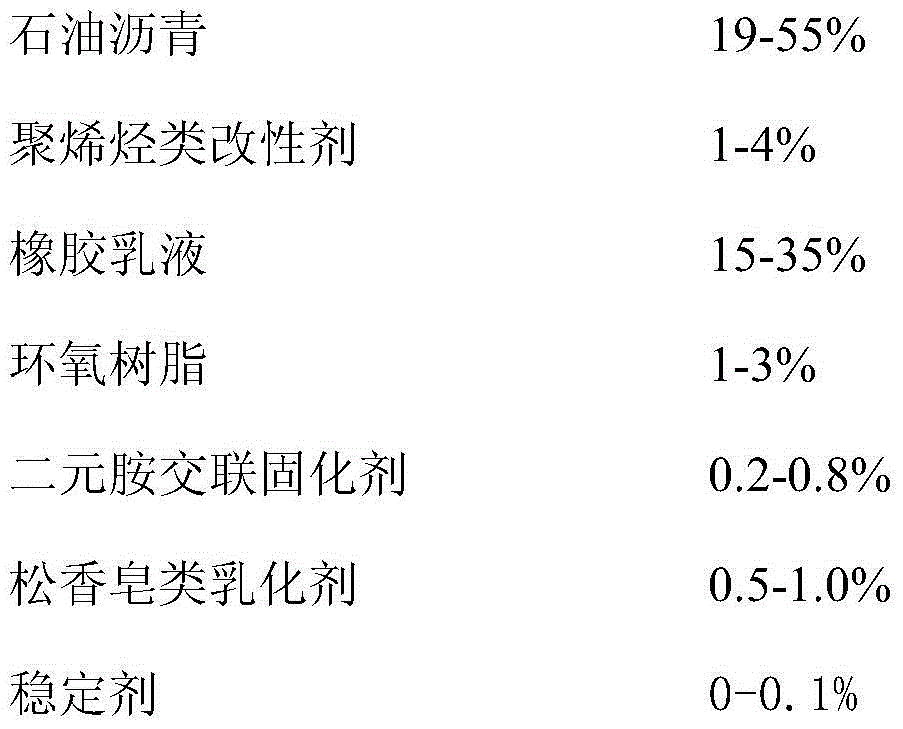

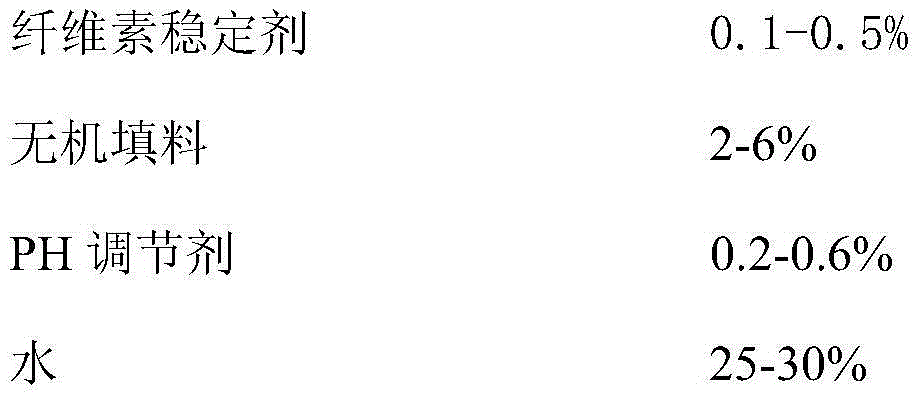

Method used

Image

Examples

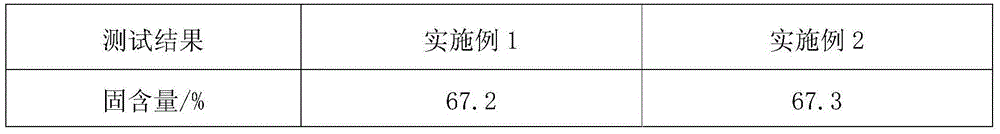

Embodiment 1

[0025] Pump 60# special asphalt for waterproof materials into the asphalt tank and heat to 160 ℃ ~ 180 ℃, add 3% APP, stir at high speed for 2 hours, then add 2% epoxy resin E51, stir for 30 minutes, and grind it through a colloid mill to prepare A good polymer modified asphalt material is stirred for 2 hours to remove foam and set aside. Pump hot water at 60°C into the soap tank, add 1% rosin soap emulsifier, 0.02% AEO-9 and 0.6% ethylenediamine, and adjust the pH value to 11 with NaOH to make soap . The prepared polymer modified asphalt and soap solution are passed through a high-speed shearing machine at the same time to form a modified emulsified asphalt emulsion with a concentration of about 60%. Add 25% neoprene latex to the emulsion, and then 2% SiO 2 , 3% bentonite and 0.2% cellulose. During the feeding process, stir slowly and continuously to disperse evenly. After the feeding is completed, keep stirring for 30 minutes, then stop stirring, add a small amount of defoa...

Embodiment 2

[0027] Pump 70# heavy-duty asphalt into the asphalt tank and heat it to 150°C-170°C, add 3% APAO, stir at high speed for 2 hours, then add 2% epoxy resin E44, stir for 30 minutes, grind it through a colloid mill, and prepare The polymer modified asphalt material was stirred for 2 hours to defoam and set aside. Pump hot water at 60°C into the soap tank, add 1% rosin soap emulsifier, 0.02% AEO-9 and 0.4% ethylenediamine, and adjust the pH value to 11 with NaOH to make soap . The prepared polymer modified asphalt and soap solution are simultaneously passed through a high-speed shearing machine to make a modified emulsified asphalt emulsion with a concentration of about 60%. Add 15% neoprene latex and 10% styrene-butadiene latex to the emulsion, and then 2% SiO 2 , 3% bentonite and 0.2% cellulose. During the feeding process, stir slowly and continuously to disperse evenly. After the feeding is completed, keep stirring for 30 minutes, then stop stirring, add a small amount of def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com