Emulsified asphalt, a preparation method thereof, applications thereof, a water-proof coating material and a water-proof coating

A technology of emulsified asphalt and emulsifier, which is applied in the direction of asphalt paint, coating, chloroprene homopolymer paint, etc. It can solve the problems of cumbersome construction process, time-consuming, insufficient waterproof coating strength, etc., and achieve high strength, The effect of high curing and setting speed and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

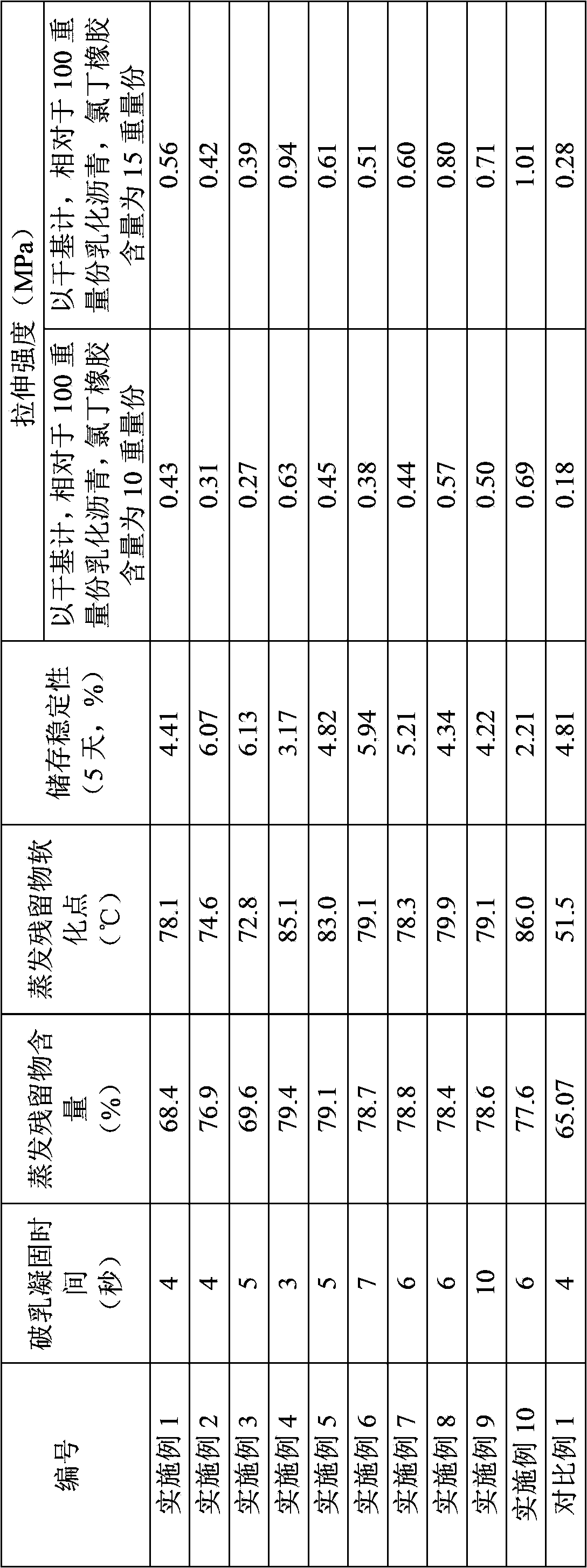

Examples

preparation example Construction

[0039] According to the method of the present invention, the polymer modified asphalt can be prepared by various methods commonly used in the art. For example, the preparation method of the polymer-modified asphalt may include: mixing base asphalt with at least one polymer modifier in the presence of a compatibilizer with or without to obtain a polymer-modified asphalt. The base asphalt can be mixed with at least one polymer modifier by various methods commonly used in the art. For example, the polymer-modified asphalt can be obtained by mixing base asphalt with a polymer modifier at a temperature of 160-180°C. From the perspective of further improving the compatibility of the base asphalt and the polymer modifier, the mixing of the base asphalt and the polymer modifier is preferably carried out in the presence of a compatibilizer. For example, at least one compatibilizer and at least one polymer modifier can be successively added to the base asphalt at a temperature of 160-1...

Embodiment 1

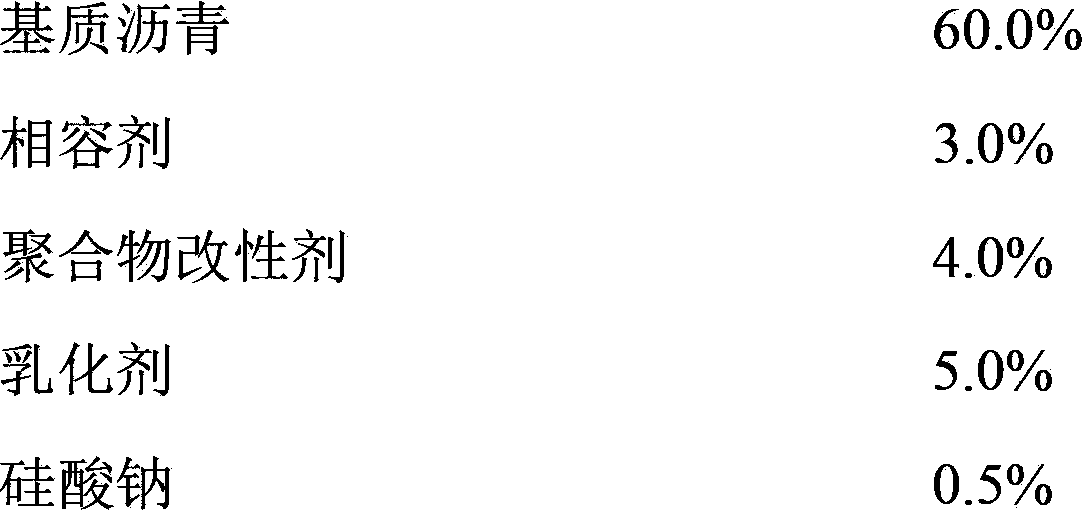

[0060] Composition formula of polymer modified emulsified asphalt (by weight):

[0061]

[0062] The balance is water

[0063] Among them, the base asphalt is No. 70 heavy traffic road asphalt commercially purchased from Zhenhai Refining and Chemical Co., Ltd., with a penetration of 68.1;

[0064] The polymer modifier is the styrene-butadiene-styrene terpolymer of SBS 1301 commercially available from Yueyang Petrochemical, wherein the total amount of styrene-butadiene-styrene terpolymer As a benchmark, the content of structural units formed by styrene is 30% by weight, and the content of structural units formed by butadiene is 70% by weight;

[0065] The compatibilizer is aromatic hydrocarbon oil (commercially purchased from Qilu Petrochemical) with an aromatic content of 70% by weight;

[0066] The emulsifier is a compound emulsifier of sodium dodecylbenzenesulfonate and ammonium stearate, and the weight ratio of the two is 1:3.

[0067] The preparation method of emulsi...

Embodiment 2

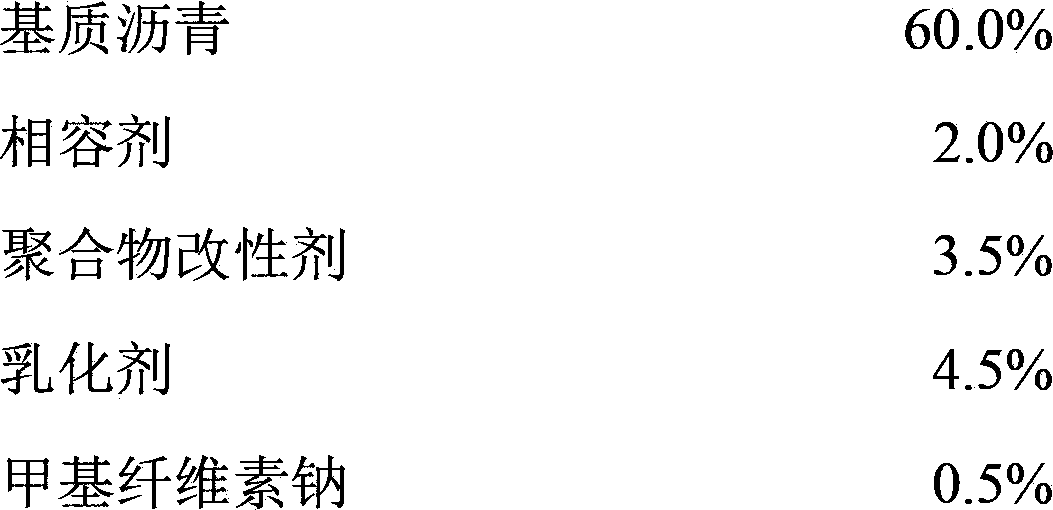

[0075] Composition formula of polymer modified emulsified asphalt (by weight):

[0076]

[0077] The balance is water

[0078] Wherein, the matrix asphalt is No. 90 heavy traffic road asphalt commercially purchased from Jinan Petrochemical, and the penetration is 94.4;

[0079] The polymer modifier is a commercially available styrene-butadiene-styrene terpolymer of SBS 1401 from Yueyang Petrochemical, wherein the total amount of styrene-butadiene-styrene terpolymer As a benchmark, the content of structural units formed by styrene is 40% by weight, and the content of structural units formed by butadiene is 60% by weight;

[0080] The compatibilizer is an aromatic oil with an aromatic content of 75% by weight (commercially purchased from Yanshan Petrochemical);

[0081] The emulsifier is ammonium stearate.

[0082] The preparation method of emulsified asphalt is:

[0083] Step 1: Provide polymer modified bitumen

[0084] Heat the base asphalt to 175°C, add a compatibiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com