Glove having butyl rubber layer to provide resistance to ketone family chemicals

a butyl rubber and solvent technology, applied in gloves, coatings, garments, etc., can solve the problems of not using different materials to enhance, and using butyl layers to provide solvent resistance to ketone family chemicals, and achieve superior or much improved solvent resistance. , good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

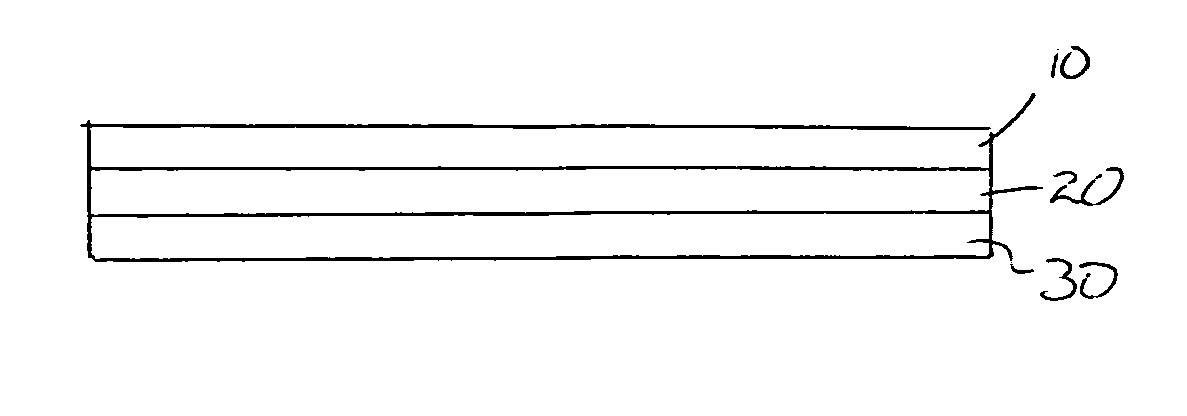

[0011] A three-layered sandwich structure shown in FIG. 1 contains an outer layer of nitrile rubber 10, a middle layer of butyl rubber 20 and an inner layer of nitrile rubber 30. This structure provides a resistance to ketone family member solvents. It is possible that other layers of other materials may be added or the three-layered sandwich structure may be repeated.

[0012] The formulation of each layer is as follows:

Nitrile LayersButyl LayerBase100parts100partsZinc Oxide1part5parts(Primary activator)Sulfur (crosslinker)1part3partsZDBC (accelerator)1part2partsTitanium Dioxide1part0parts(optional)BHT (antioxidant)1part1partColor pigment0parts0parts(optional)

The base of the nitrile layer may be natural rubber latex or nitrile. Throughout the specification, the term ‘nitrile’ is used to encompass these two materials. The base for the butyl layer is butyl latex.

[0013] Laminates made in accordance with the invention have demonstrated the following resistance:

AcetoneButyl layerTot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structure | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com