Preparation method and application of microbial inoculant for remediating poly-halohydrocarbon-polluted soil

A technology of polyhalogenated hydrocarbons and polluted soil, applied in the field of soil remediation in environmental engineering, can solve the problems of limiting the large-scale application of bioaugmentation technology and high cost, and achieve the effect of low cost, low content of heavy metals, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

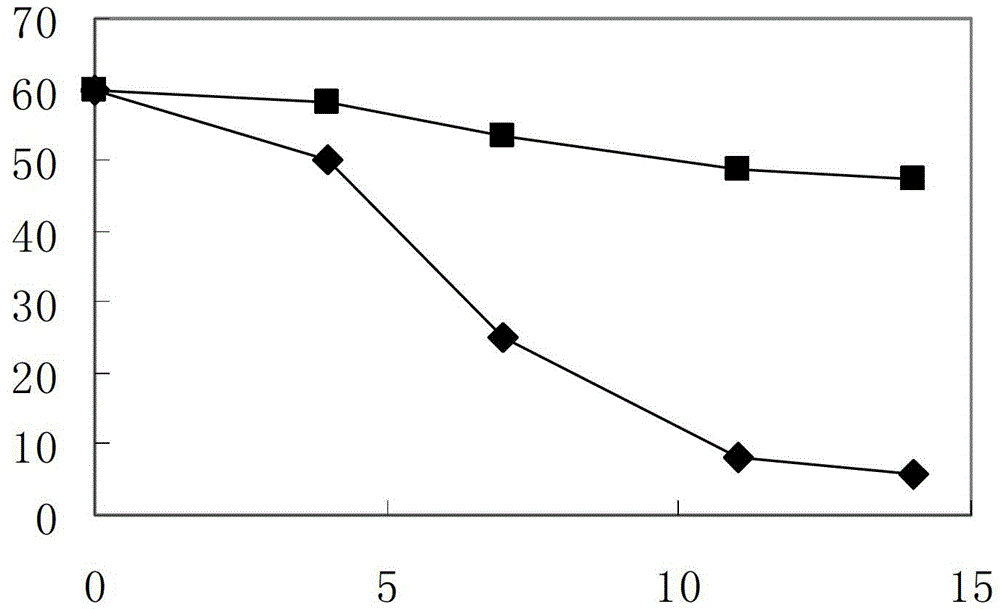

Image

Examples

Embodiment 1

[0027] [1] Preparation of residual sludge lysate

[0028] Take the remaining sludge from the urban sewage treatment plant, adjust its concentration to 30g / L, control the initial pH at 11, control the pyrolysis temperature at 120°C, and control the pyrolysis time at 0.5 hours. Centrifuge the sludge lysate obtained above at 4000r / min After 30 minutes, collect the sludge lysate supernatant, and recover the precipitate.

[0029] [2] Culture substrate optimization

[0030] Divide the sludge cracking supernatant obtained in step [1] into two parts of equal volume, adjust the pH of one part to 2.0, let it stand for 18 hours, recover the sediment, and combine the remaining supernatant with another part of sludge cracking After the serum was mixed, an optimized culture substrate was obtained for the cultivation of degrading bacteria.

[0031] [3] Bacteria preparation

[0032] First, the quinone-reducing facultative anaerobic bacteria Shewanella oneidensis MR-1 (ATCC 700550) was inoc...

Embodiment 2

[0036] [1] Preparation of residual sludge lysate

[0037] Take the remaining sludge from the urban sewage treatment plant, adjust its concentration to 30g / L, control the initial pH at 11, control the pyrolysis temperature at 90°C, and control the pyrolysis time at 2 hours. Centrifuge the sludge lysate obtained above at 6000r / min After 20 minutes, the sludge lysed supernatant was collected, and the precipitate was recovered.

[0038] [2] Culture substrate optimization

[0039] Divide the sludge cracking supernatant obtained in step [1] into two parts of equal volume, adjust the pH of one part to 2.0, let it stand for 24 hours, recover the sediment, and combine the remaining supernatant with another part of sludge cracking After the serum was mixed, an optimized culture substrate was obtained for the cultivation of degrading bacteria.

[0040] [3] Bacteria preparation

[0041] First, the quinone-reducing facultative anaerobic bacteria Shewanella putrefaciens (1A02627) was ino...

Embodiment 3

[0045] [1] Preparation of residual sludge lysate

[0046] Take the remaining sludge from the urban sewage treatment plant, adjust its concentration to 30g / L, control the initial pH at 12, control the pyrolysis temperature at 115°C, and control the pyrolysis time at 1 hour, and centrifuge the sludge lysate obtained above at 4000r / min After 30 minutes, collect the sludge lysate supernatant, and recover the precipitate.

[0047] [2] Culture substrate optimization

[0048] Divide the sludge cracking supernatant obtained in step [1] into two parts of equal volume, adjust the pH of one part to 2.0, let it stand for 18 hours, recover the sediment, and combine the remaining supernatant with another part of sludge cracking After the serum was mixed, an optimized culture substrate was obtained for the cultivation of degrading bacteria.

[0049] [3] Bacteria preparation

[0050] First, the quinone-reducing facultative anaerobic bacteria Shewanella oneidensis MR-1 (ATCC 700550) was inocu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com