Patents

Literature

44results about How to "Improve heat and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

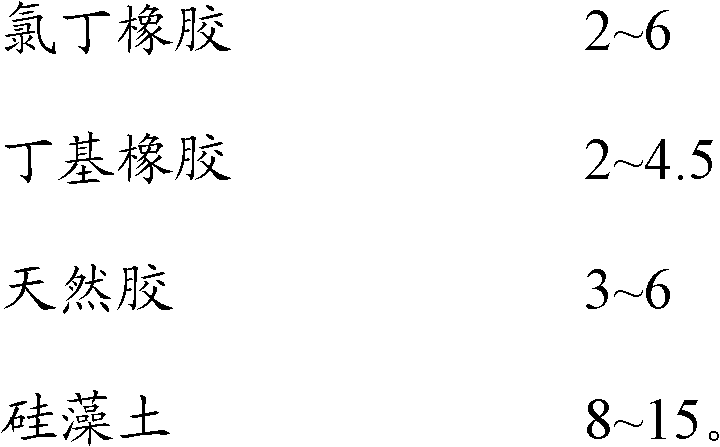

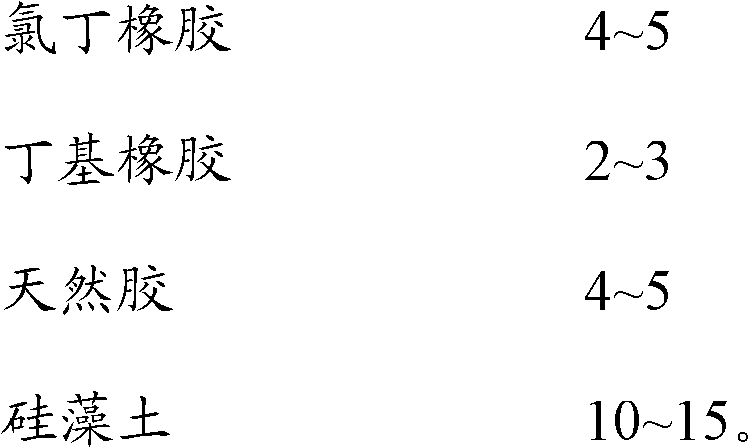

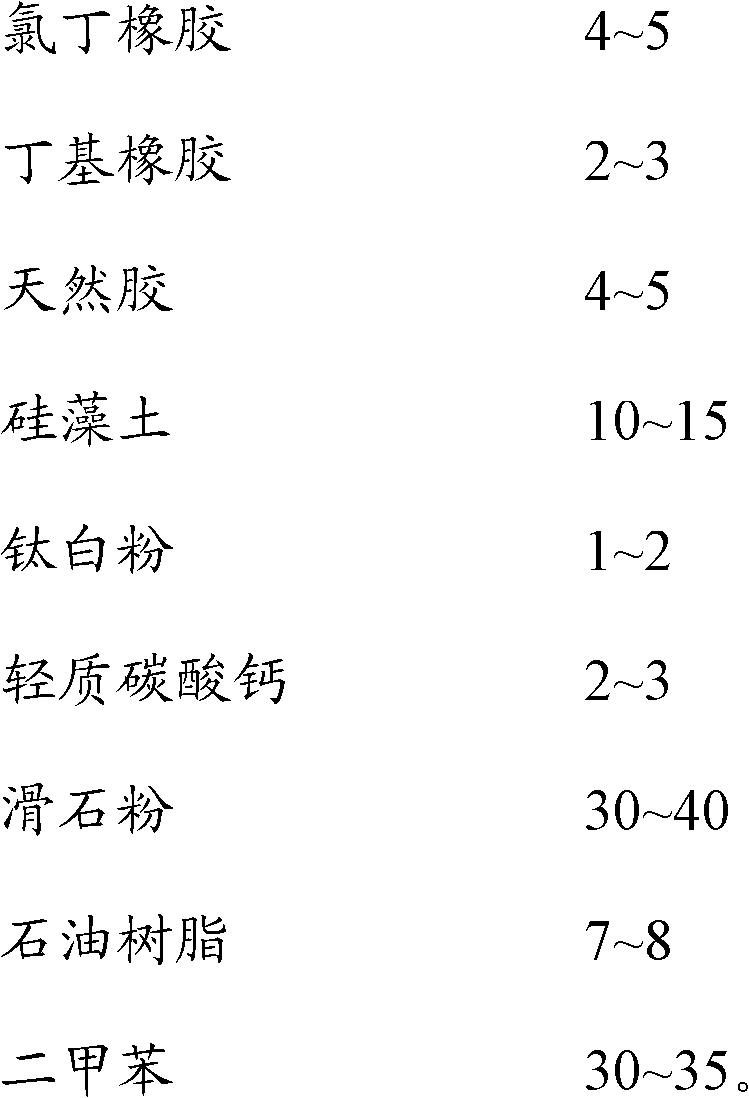

Diatomite chloroprene type sealant

InactiveCN102504722AHigh porosityStrong absorptionNatural rubber adhesivesNon-macromolecular adhesive additivesWeather resistanceHeat resistance

The invention belongs to the technical field of sealants, and specifically to a diatomite chloroprene type sealant. The diatomite polychloroprene type sealant is prepared by carrying out milling and kneading the following materials according to a formula, wherein the materials comprise chloroprene rubber, butyl rubber, natural rubber, diatomite, a reinforcing agent, a filler, a viscosity regulator, a vulcanizing agent, a stabilizer and other commonly used additives. According to the present invention, the diatomite has a special structure and physical properties, the other raw materials in the formula are reasonably selected, the ratio is appropriate, and the diatomite chloroprene type sealant has characteristics of good anti-aging performance, good weather resistance, strong heat resistance, strong wear resistance, rare sagging, good surface smoothness, environmental protection, and long service life, and can be used for family decoration and other fields.

Owner:TIANCHANG CITY TONGTIAN CHEM

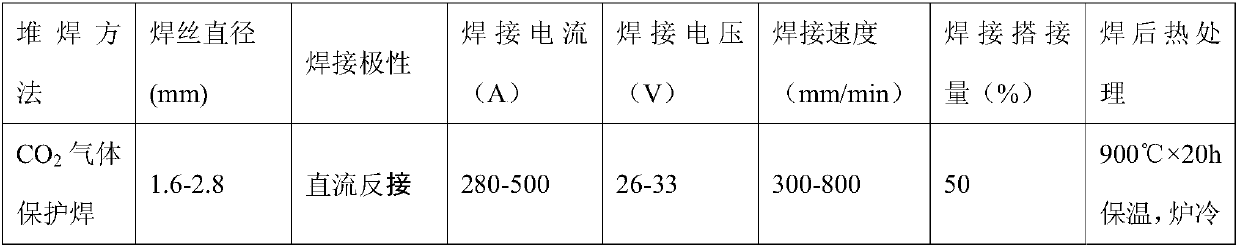

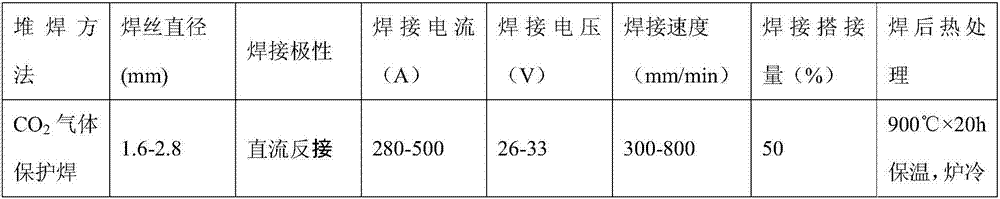

Heat-resisting and wear-resisting flux-cored wire

ActiveCN105945456ANon-spontaneous nucleationOptimize the reasonable rangeWelding/cutting media/materialsSoldering mediaRare-earth elementNiobium

The invention belongs to the technical field of metal surfacing materials and particularly relates to a heat-resisting and wear-resisting flux-cored wire. The heat-resisting and wear-resisting flux-cored wire is formed by wrapping a low-carbon cold-rolled steel strip on flux core powder. The flux core powder comprises, by weight, 0.25-1.0% of graphene, 40-45% of chromium metal, 5-9% of electrode graphite, 2-4% of marble, 1-3% of chromium carbide, 1-4% of electrolytic manganese metal, 3-6% of silicon iron, 4-6% of molybdenum, 6-10% of nickel, 2-4% of ferro-boron, 0.5-3% of niobium, 0.5-3.0% of tungsten, 0.5-1% of rare earth, and the balance FHY100.25 reduced iron powder. According to the heat-resisting and wear-resisting flux-cored wire, weld metal structures are refined and homogenized by adding components such as graphene, rare earth elements and chromium carbide into the flux core powder and optimizing the reasonable range of components, and the high-temperature tempering stability of surfacing metal is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

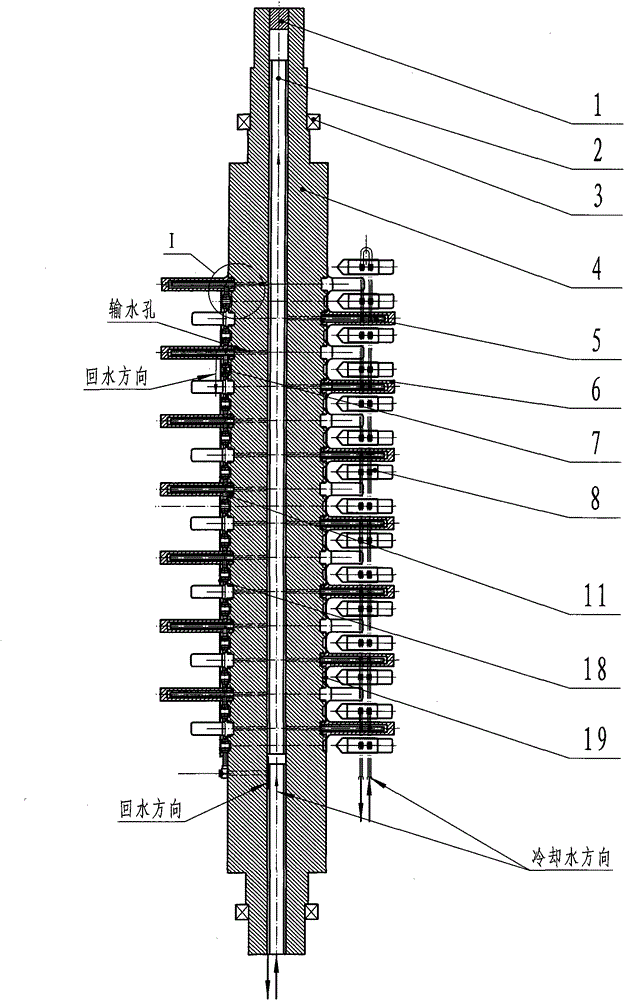

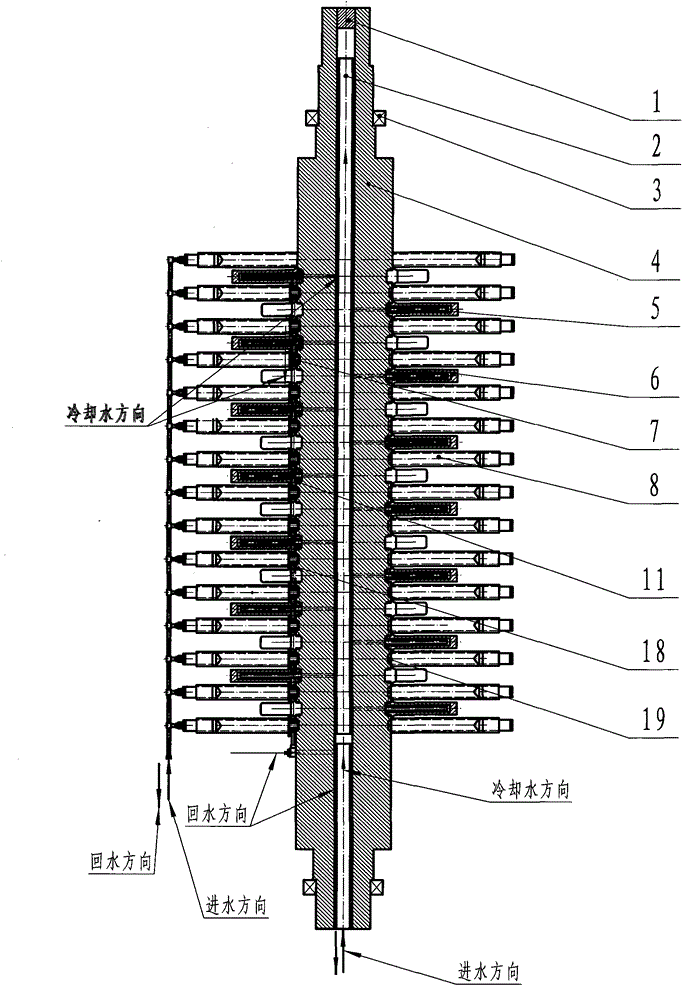

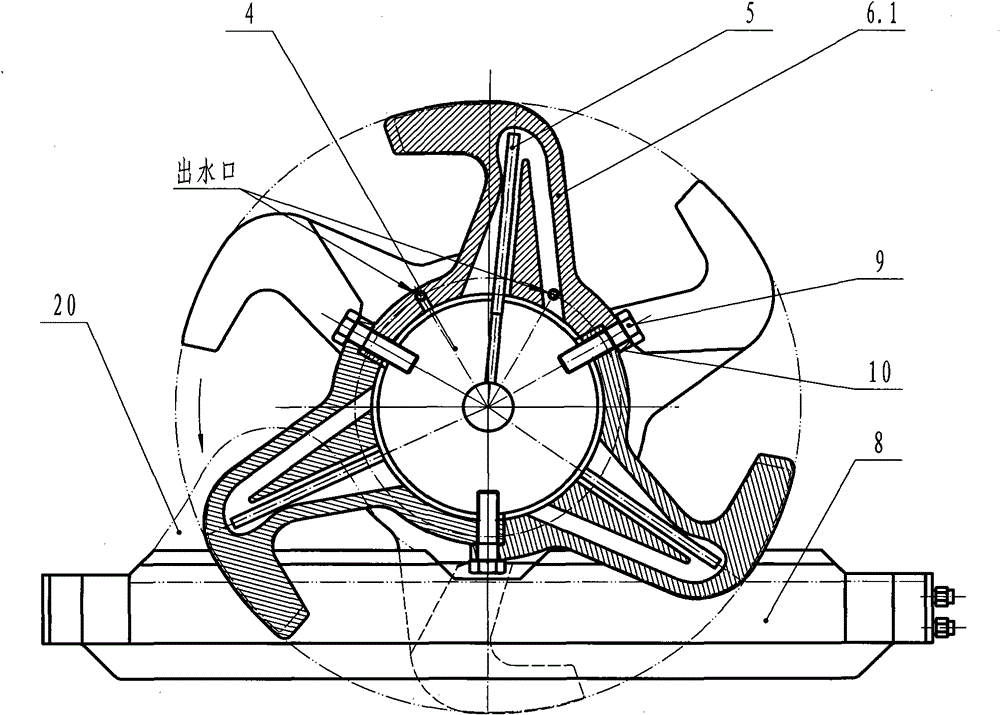

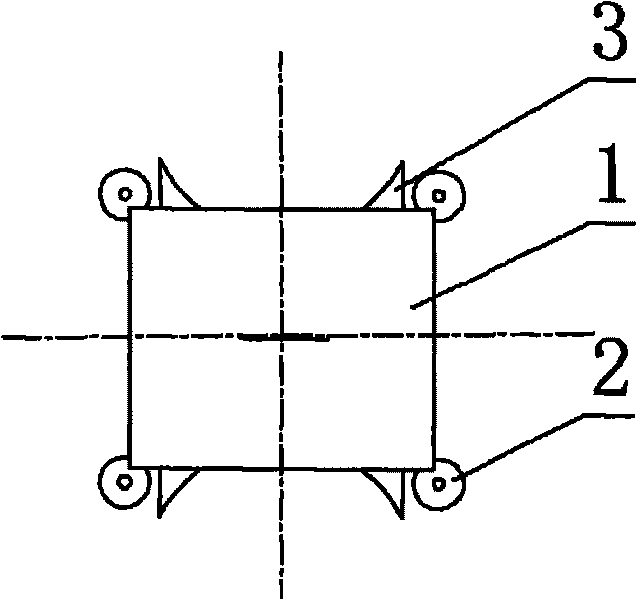

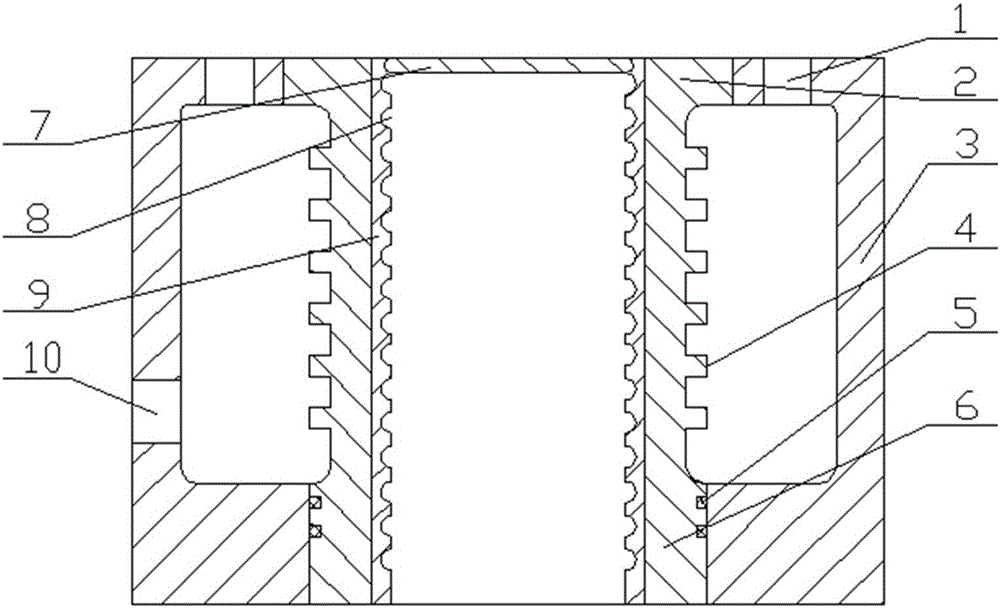

Tooth roller and grate of single-tooth roller crusher

InactiveCN102744120AIncrease water flow areaGood cooling effectGrain treatmentsMaterials processingSingle tooth

The invention discloses a tooth roller and a grate of a single-tooth roller crusher for crushing sinter cakes, belonging to the field of initial material processing in metal smelting industry. The invention is characterized in that: the tooth roller is produced by inlaying 5-14 crushing toothed rings in a tooth roller that can be available for inlay, the grate is produced by surfacing a grate basic body or conducting secondary casting to form a layer of wear-resisting alloy, wherein the crushing toothed rings comprises 3-4 hocks which are mutually occluded and arranged together in order, a layer of the wear-resisting alloy is formed by surfacing or carrying out secondary casting on the crown and periphery of the hock, the grate basic body is produced by sealing a cast steel groove-shaped body, a water-stop sheet and a sealing cover by welding, and the crushing toothed rings, tooth roller and grate basic body are all can be prepared into a water cooling structure and a half-water cooling structure. According to the invention, the tooth roller and the grate of the full water cooling single-tooth roller crusher have excellent heat resistance and wear resistance because of large flow area and good cooling effect, the processing technology of the hock, the tooth roller and the grate is simple, the replacement is convenient, the cost of processing and maintenance is reduced, and the hock and the grate has good repairability.

Owner:郭振洲

Aluminum-plastic composite film for flexible packaging of lithium battery

ActiveCN107825773AStrong bondExtended service lifeSynthetic resin layered productsMacromolecular adhesive additivesComposite filmPolyolefin

The invention discloses an aluminum-plastic composite film for flexible packaging of a lithium battery. The aluminum-plastic composite film comprises a wear-resistant layer, a first bonding layer, analuminum foil layer, a passivation layer, a second bonding layer having corrosion resistance and a heat sealing layer which are sequentially arranged from the outside to the inside, and the passivation layer comprises, by weight, 100 parts of acrylic resin, 5-15 parts of a chromium-containing compound, 1-5 parts of a phenyltrimethylsilane coupling agent, 1-5 parts of a titanate coupling agent and30-50 parts of water; and the second bonding layer having corrosion resistance includes, by weight, 100 parts of acid-modified polyolefin resin, 1-5 parts of an epoxy system curing agent, 1-5 parts offluorine-containing micro-powder, 10-20 parts of a cyclohexane solvent and 20-40 parts of a butanone solvent. The aluminum-plastic composite film has the advantages of obviously improved electrolyteresistance, stability in bonding among the first bonding layer, the aluminum foil layer, the passivation layer, the second bonding layer having corrosion resistance and the heat sealing layer, high deep-drawing intensity and long service life.

Owner:ZHEJIANG GREEN NEW MATERIALS

Process for preparing WC hard alloy coating through laser cladding of hot rolling bar apron board roller way

ActiveCN104250810AYouyi Thermal Abrasion ResistanceImprove heat and wear resistanceMetallic material coating processesCarbide coatingBoron nitride

The invention relates to a process for preparing a WC hard alloy coating through laser cladding of a hot rolling bar apron board roller way, which is characterized in that weight percentage of spherical casting tungsten carbide is 40-60%, a nickel-based alloy is a bonding phase with weight percentage of 60-40%. The process comprises the following steps: preparing and mixing, machining an operational layer and cleaning the surface, removing oil stain by a solvent or a cleaning compound, removing a rust layer by polishing or sandblasting; performing laser cladding treatment, selecting the bonding phase and the spherical casting tungsten carbide powder with appropriate proportion, adjusting powder feeding rate of an automatic powder feeding apparatus for satisfying the powder feeding rate required by the coat layer thickness; and employing diamond or cubic boron nitride for grinding and processing the cemented carbide coating through laser cladding to the required size. On the hot rolling bar apron board roller way with a common stainless steel material, the WC hard alloy coating with thermal wear resistance is formed on a matrix through laser cladding, service life of the hot rolling bar apron board roller way can be increased, and the laser manufacture of the hot rolling bar apron board roller way can be realized.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

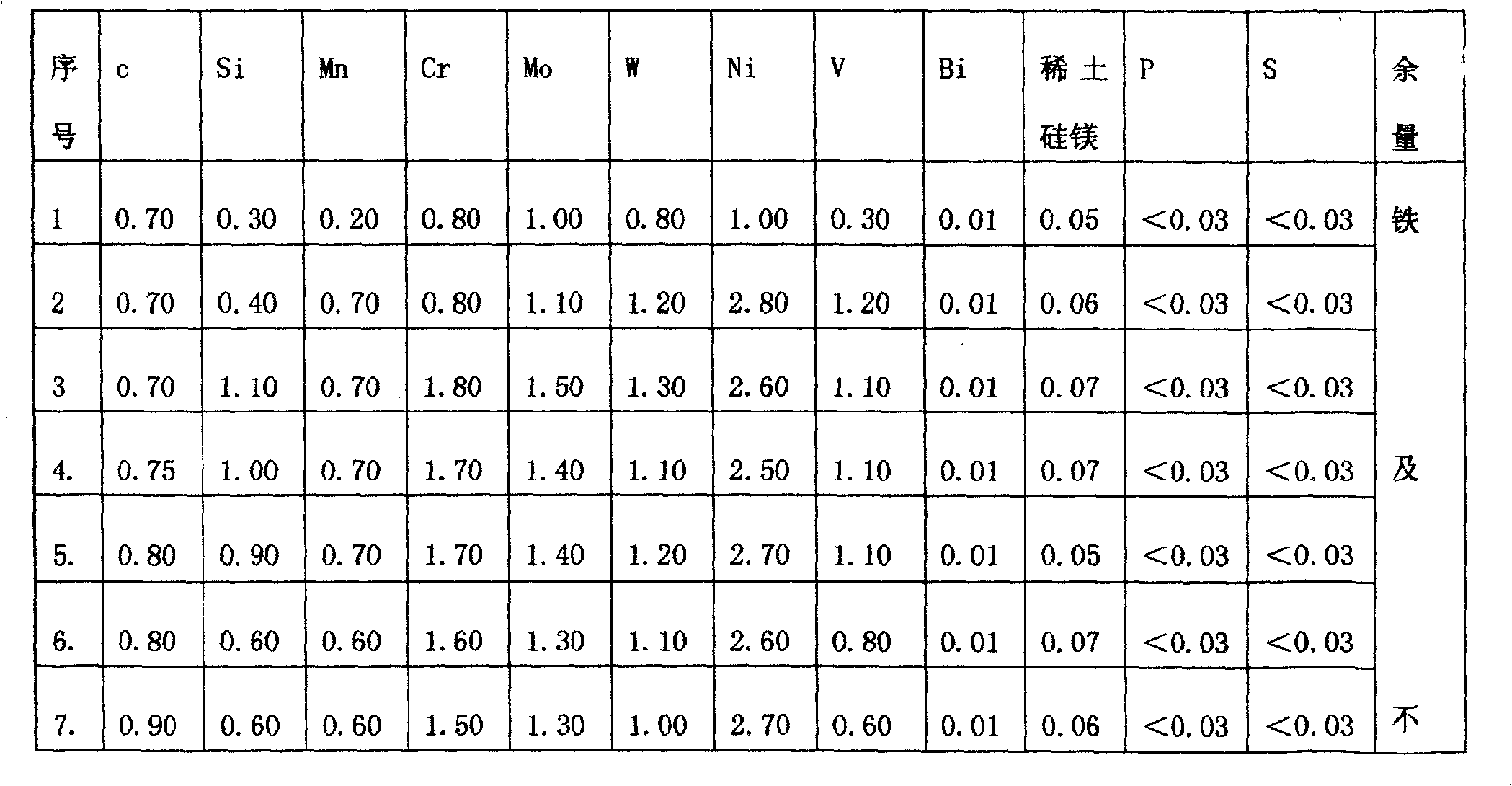

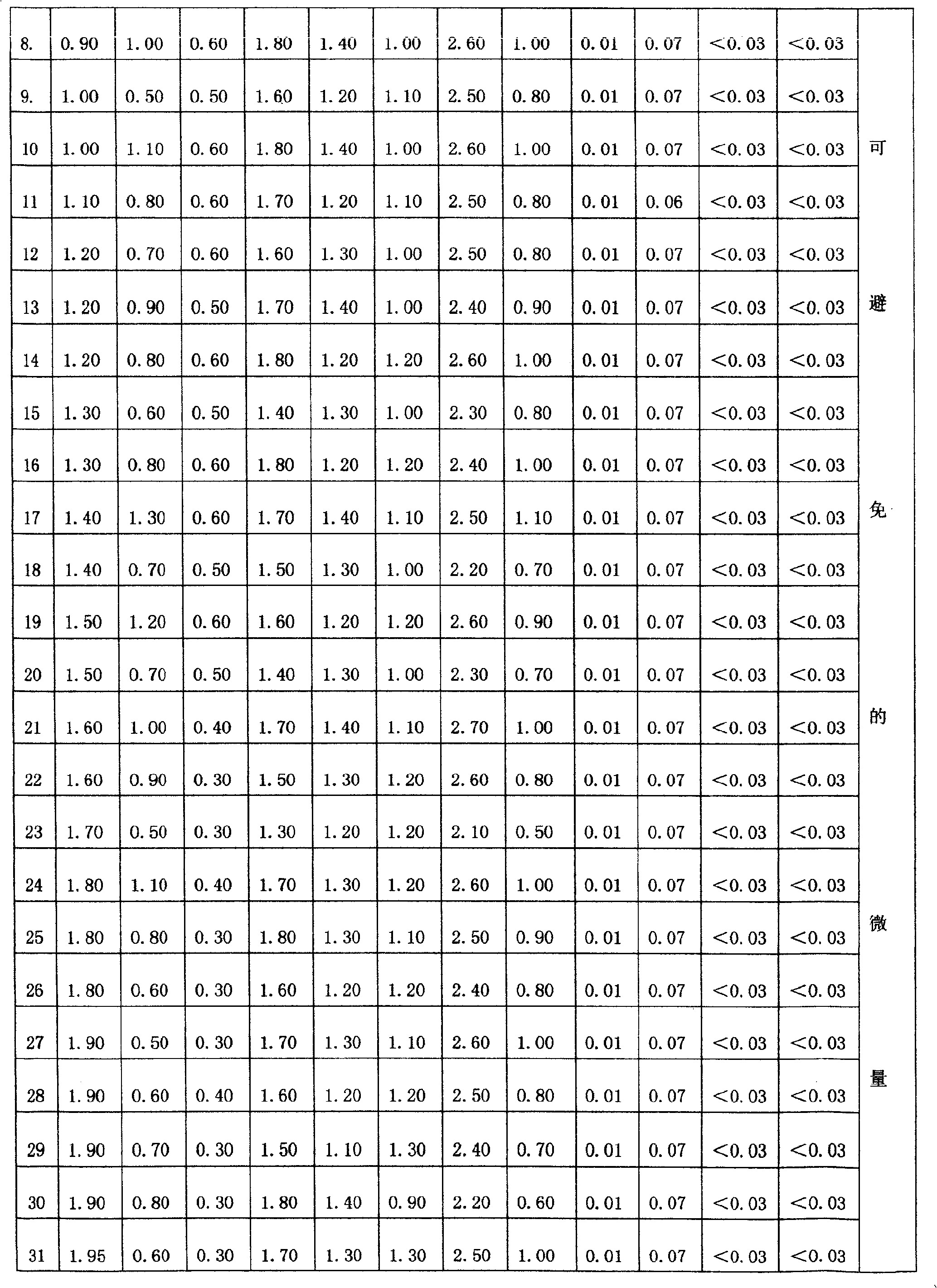

High performance hot work mould steel

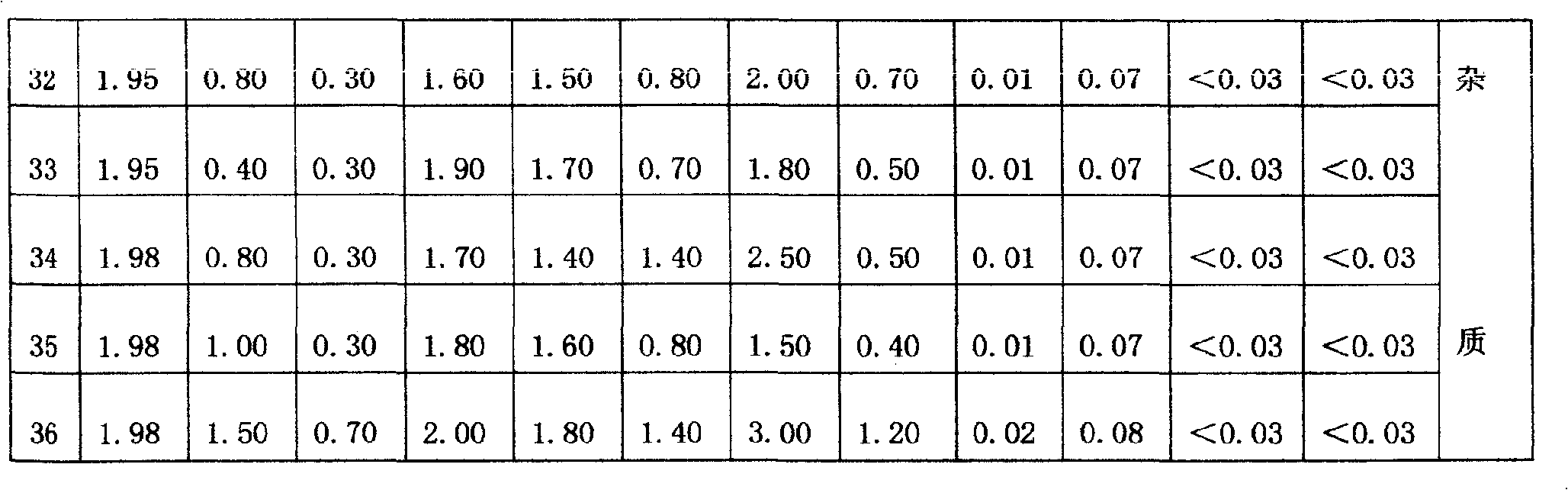

This high performance hot-work die steel accounting for weight has following chemical composition: C: 0.70-1.98,Si:0.30-1.50,Mn:0.20-0.70,Cr:0.80-2.00,W:0.80- 1.40,Mo:1.00-1.80,Ni:1.00-3.00,V:0.30-1.20,Bi:0.01-0.02,rare earth Si and Mg:0.05-0.08,P<0.03,S<0.03, the rest is Fe and inevitable impurity. The HRC hardness of it can be adjust by need from 20-60 degree, through the way of heat treatment such as annealing and quenching. The invention has enough mechanical strength and toughness, super ordinary thermal oxidation resistance and cold-heat impact resistance, heat resistance, wear resistance, and aluminium liquid resistance. After process into die, not need surface treatment of 'nitriding', just need quenching and tempering for needed hardness.

Owner:易正伦

Method for preparing wear-resistant heat-resistant coating through laser cladding of surface of guide roller by bar rolling mill

InactiveCN104250805AImprove wear resistanceGood claddingMetallic material coating processesWear resistantRoom temperature

The invention relates to a method for preparing a wear-resistant heat-resistant coating through laser cladding of surface of a guide roller by a bar rolling mill, which comprises the following steps: removing oil and rust on the surface of the guide roller under room temperature; preparing alloy powder B with weight percentage of 15-50% in an A+B hard alloy composite powder; adjusting an automatic powder feeding apparatus so that the alloy powder from an automatic powder feeding head just falls in a laser molten pool, adjusting the powder feeding amount so that the coating thickness of the alloy powder can reach 0.8-2mm; selecting a 3.5*1mm broadband integration mirror, and adjusting the defocus amount for laser cladding, and forming an uniform and compact laser cladding layer on the surface of the guide roller. The hard alloy composite powder has good metallurgy and mechanical compatibility with a guide roller matrix, cladding layer thickness is 0.8-2.0mm, the hardness and thickness are uniform, and no crack and spalling phenomena can be generated.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Resin-based high-viscosity heat-resistant grinding wheel material

InactiveCN107400330AImprove heat and wear resistanceHigh strengthAbrasion apparatusWear resistantAzodicarbonamide

The invention discloses a resin-based high-viscosity heat-resistant grinding wheel material, which is prepared from the following raw materials: modified phenolic resin, bisphenol-A epoxy resin, silicon resin, polyimide resin, bismaleimide, zinc stearate, graphite, precipitated calcium carbonate, titanium dioxide, diamond, cerium oxide, talcum powder, silicon carbide, silica, silicon nitride, aluminum oxide, boric oxide, boron nitride, azodicarbonamide, imidazole, phenyltrimethoxysilane, 4,4-dioxylbisbenzensulfonyl hydrazide, a silane coupling agent KH-570 and a wear-resistant additive. The prepared resin-based high-viscosity heat-resistant grinding wheel material has excellent wear-resisting property, good adhesion and high hardness; the heat resistance and the hardness of a resin grinding wheel are improved; cracks formed by rigid grinding is reduced; heat dissipation is fast; dispersion of a lot of heat released from the grinding wheel in the cutting process is facilitated; and the resin-based high-viscosity heat-resistant grinding wheel material plays a role in reducing the cutting temperature.

Owner:安徽昌悌进出口贸易有限公司

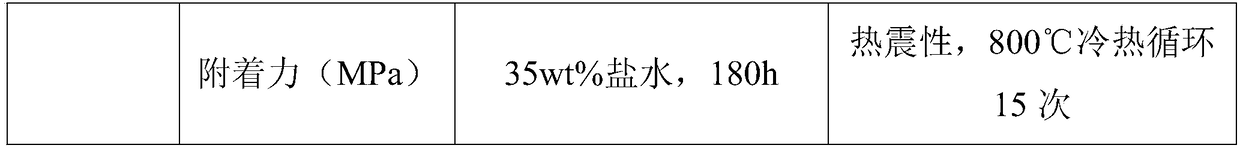

Fluorine nanometer composite modified anticorrosion paint

InactiveCN106398499AImprove compactnessImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention relates to a fluorine nanometer composite modified anticorrosion paint, comprising 32 to 55 parts of waterborne polyurethane emulsion, 28 to 43 parts of epoxy resin, 8 to 15 parts of modified nanometer titanium dioxide, 11 to 19 parts of fluorine polymer, 7 to 14 parts of pigment, 0.3 to 0.8 part of a catalyst triethylamine and 12 to 17 parts of an auxiliary agent. A preparation method for the paint comprises the following steps: step 1, preparing modified nanometer titanium dioxide; step 2, preparation of a fluorine polymer; and step 3, compounding of the anticorrosion paint. According to the invention, the volume-filling density of a carrier is improved through nanometer titanium dioxide, so capillary action is reduced and shielding density is greatly improved; a film structure can be filled with tiny particles of a nano-material, so the density of a film is enhanced, permeability of the film is reduced, and corrosion of water, oxygen and the like to a metal substrate is efficiently blocked; thus, the anticorrosion performance of the paint is improved.

Owner:中国人民解放军空军勤务学院

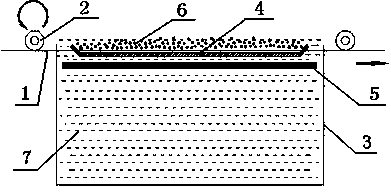

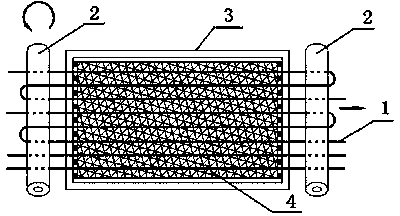

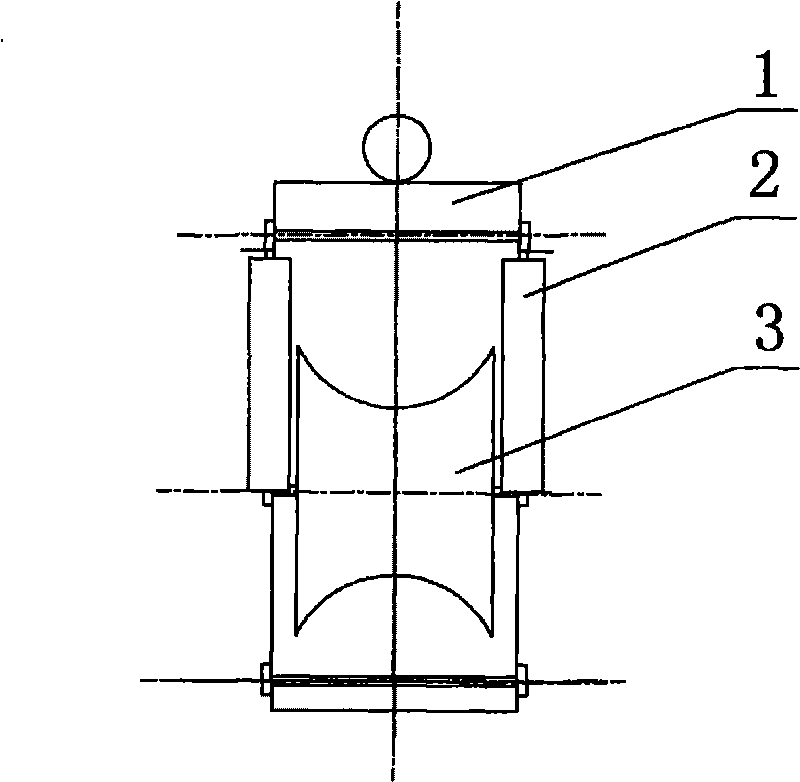

Continuous composite plating sand overlying tank for diamond cutting line

ActiveCN103898595AImprove plating efficiencyHigh controllability of coating qualityElectrolysis componentsElectrolytic coatingsDiamond cuttingElectroplating

The invention discloses a continuous composite plating sand overlying tank for a diamond cutting line. The continuous composite plating sand overlying tank comprises an electroplating bath body, a cathode roller, an anode rack, a sand loading tank and a wire guiding wheel, wherein the cathode roller is connected with the cathode of a power supply, and the anode rack is connected with the anode of the power supply; the cathode roller is arranged on the outer side of the electroplating bath body; a plating solution is filled in the electroplating bath body; diamond micro-powder is loaded by the sand loading tank; the anode rack, the sand loading tank and a cutting steel wire wound at the upper part and lower part of the cathode roller are submerged in the plating solution; the anode rack is fixed below the sand loading tank; the cutting steel wire below the cathode roller is buried in the diamond micro-powder. The composite plating sand overlying tank has the characteristics of high electroplating efficiency, high controllability on the length of the needed electroplating bath body and the plating quality, strong binding force of cutting line diamond with a base body, good heat-resisting and abrasion-resisting properties and high cutting efficiency.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Heat-proof wear-proof nano anti-corrosion coating material

InactiveCN109401544AImprove adhesionImprove bindingFireproof paintsAnti-corrosive paintsEmulsionDefoaming Agents

The invention provides a heat-proof wear-proof nano anti-corrosion coating material. The heat-proof wear-proof nano anti-corrosion coating material is prepared from the following components in parts by weight: 40 to 60 parts of epoxy resin emulsion, 20 to 30 parts of modified organic silicon resin, 6 to 12 parts of modified nano titanium nitride, 5 to 10 parts of bentonite, 10 to 16 parts of ceramic powder, 10 to 16 parts of graphite powder, 2 to 6 parts of a coalescing agent, 0.1 to 0.5 parts of a dispersing agent, 0.6 to 1.2 parts of pigment, 0.1 to 0.5 part of a defoaming agent and 20 to 30parts of water, wherein the modified organic silicon resin is mainly prepared from organic silicon resin, acrylic acid, an initiator and silica sol; the modified nano titanium nitride is mainly prepared from nano titanium nitride and sodium dodecyl sulfonate. The heat-proof wear-proof nano anti-corrosion coating material provided by the invention not only is good in corrosion resistance, but alsohas very good heat-proof and wear-proof properties.

Owner:合肥晓拂新能源有限公司

Surface weather-resistant coating for mining machinery

InactiveCN107974112AImprove curing effectEffective protectionCoatingsDiethylene glycol monobutyl etherMethacrylate

The invention discloses a surface weather-resistant coating for mining machinery, and relates to the technical field of the mining machinery. The surface weather-resistant coating is prepared from thefollowing components: sodium diacetate, turpentine oil, zinc naphthenate, polyacrylamide, pigment, propylene glycol, waterborne acrylic resin, a defoaming agent, calcium carbonate powder, bamboo fibers, 8-hydroxyquinoline, diethylene glycol monobutyl ether, bisepoxyl glycol diglycidyl ether, diacetone acrylamide, amine sorbate, hexafluorobutyl methacrylate, chitosan modified nano-alumina and film-forming resin. After the surface weather-resistant coating for the mining machinery is sprayed onto the surfaces of the mining machinery, the solidification effect of the surface weather-resistant coating on the mining machinery is good, and the mining machinery can be effectively protected; the surface weather-resistant coating is good in heat resistance and wear resistance, and has good weatherresistance.

Owner:马鞍山市恒特重工科技有限公司

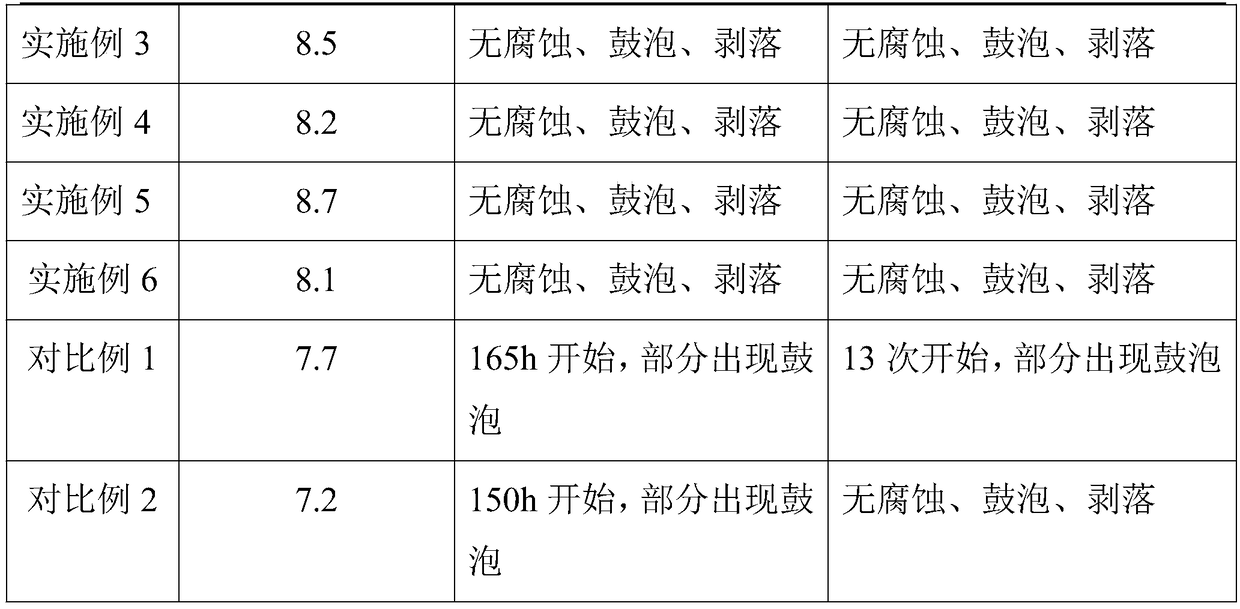

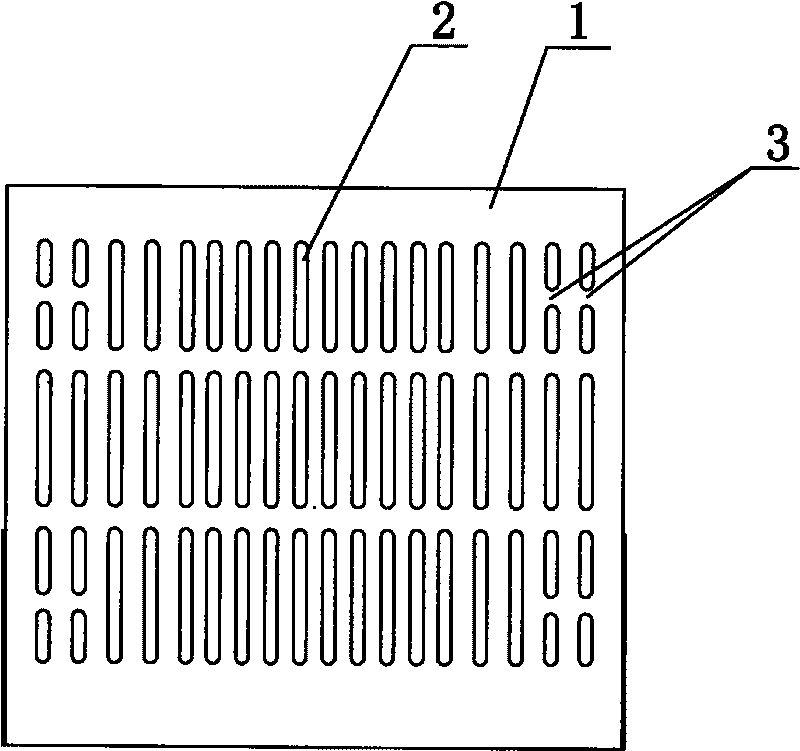

Grate plate of pellet traveling grate and preparation method thereof

InactiveCN101709917AImprove antioxidantImprove heat and wear resistanceFoundry mouldsFurnace typesOxidation resistantSilanes

A grate plate of a pellet traveling grate and a preparation method thereof relate to a structural technology of the grate plate of the traveling grate in the iron and steel smelting pellet technology. The preparation method comprises the following steps: hot-melting the alloy formed by C, Si, Mn, Cr, Mo, W, Ni, Al, V, P and S elements, pouring in the casting box formed by moulding sand, curing agent, silane and resin, cooling, demoulding, quenching at 1000-1100 DEG C, and finally tempering to prepare the grate plate of the pellet traveling grate, wherein the plate body of the grate plate is provided with at least two rows of long through-holes, and the through-holes at the four corners of the plate body are provided with connection ribs which are vertical to the length direction of the through-holes. Therefore, the fracture resistance, fatigue resistance, oxidation resistance, heat resistance and wear resistance of the product are enhanced, the expansion coefficient is reasonable, and the service life is up to 16-18 months. As the grate plate of the invention has good overall performance, needs a little repair and saves the raw material, the labor intensity of users and the production cost are significantly reduced so as to realize efficient, energy-saving and environmentally friendly production.

Owner:江苏明雨耐磨材料有限公司

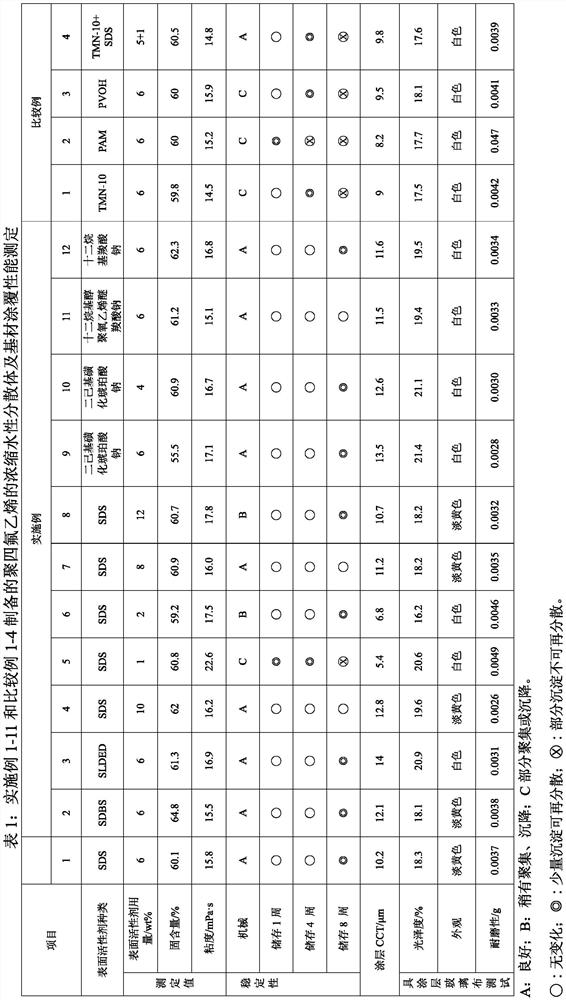

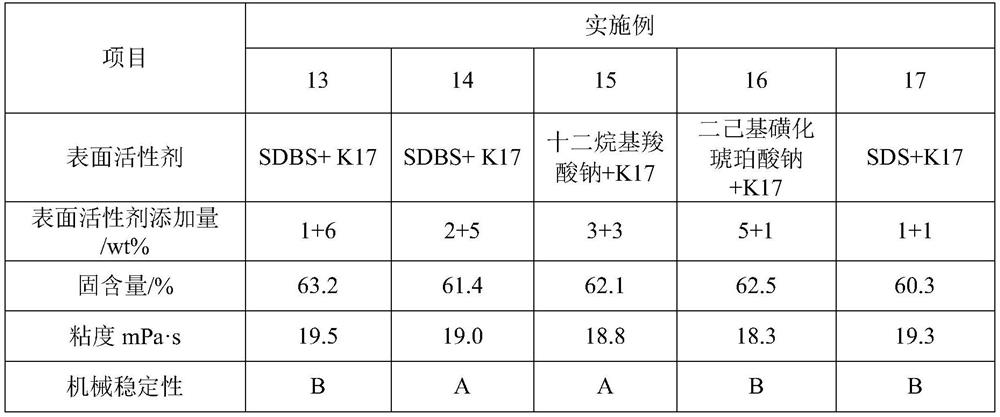

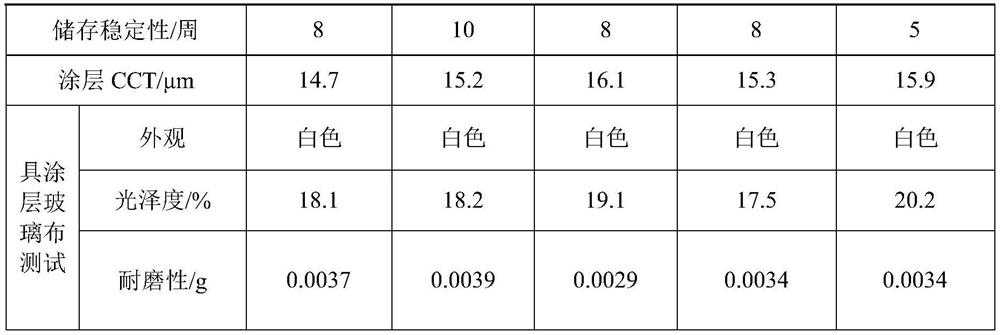

Concentrated aqueous dispersion of fluorine-containing polymer as well as preparation method and application of concentrated aqueous dispersion

PendingCN114381013ALow viscosityPromote degradationAbrasion resistant fibresActive agentPyrrolidinones

The invention discloses a concentrated aqueous dispersion of a fluorine-containing polymer as well as a preparation method and application of the concentrated aqueous dispersion, and belongs to the technical field of coatings. A concentrated aqueous dispersion of a fluorine-containing polymer according to the present invention comprises fluorine-containing polymer particles dispersed in an aqueous solvent, an anionic surfactant, and an optional nonionic surfactant selected from a polyvinylpyrrolidone-based polymer represented by formula (I), and does not comprise a polyoxyethylene ether-based surfactant. The total content of the anionic surfactant and the optional nonionic surfactant is from 2 to 16 wt% based on the weight of the fluoropolymer particles. The concentrated aqueous dispersion of the fluorine-containing polymer disclosed by the invention has the characteristics of low viscosity and good stability, is environment-friendly, can be used for producing a fluorine-containing polymer anti-dripping agent, impregnated porous glass and porous metal or used as a coating, and has the characteristics of good appearance, wear resistance and the like.

Owner:SHINE POLYMER (ZHUHAI) CO LTD

Roller type tube protecting device for medicament delivery rubber tube of emulsifying mix-load vehicle

InactiveCN101709020AImprove heat and wear resistanceReduce wearExplosive working-up apparatusWear resistantHeat resistance

The invention relates to the technical field of mechanical equipment, in particular to a roller type tube protecting device for a medicament delivery rubber tube of an emulsifying mix-load vehicle. The roller type tube protecting device comprises a support and a pulley, and is characterized in that: the upper part of the support and the front side, the back side, the left side and the right side near the edge part of the pulley are respectively provided with a roller; each roller is provided with an oil hole to prevent a shaft core of the roller from being corroded and oxidized; the roller is made of heat-resistant and wear-resistant materials, and also can be prevented from causing sparkles during friction with the rubber tube. The roller type tube protecting device for the medicament delivery rubber tube of the emulsifying mix-load vehicle has the characteristics of simple structure, good effects of heat resistance and wear resistance, and has the considerable economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

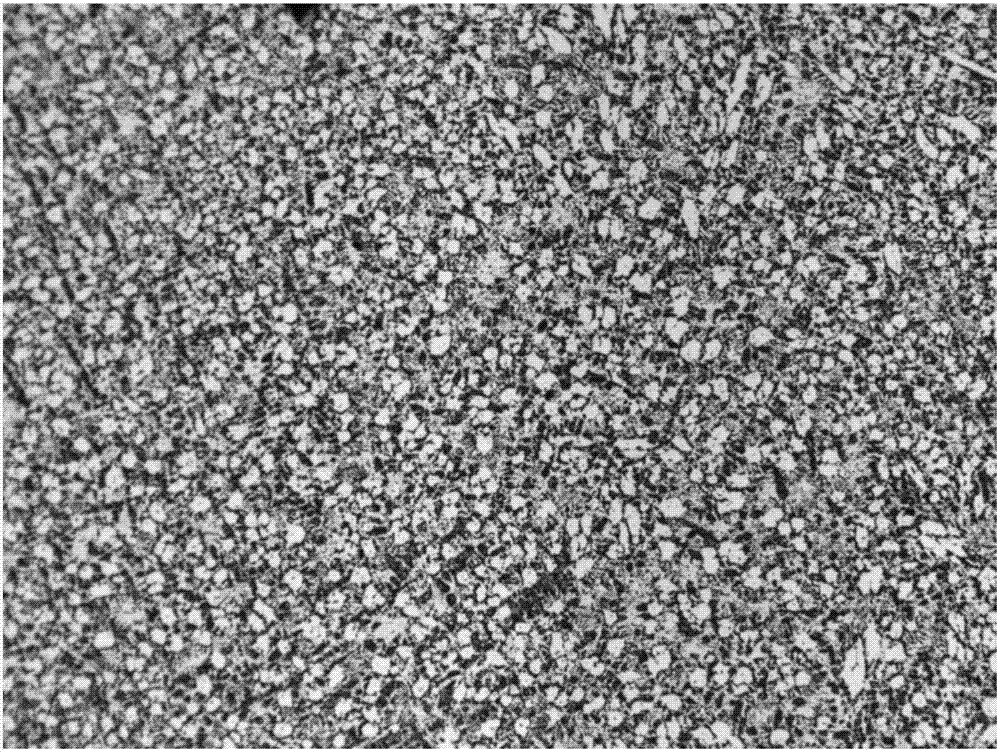

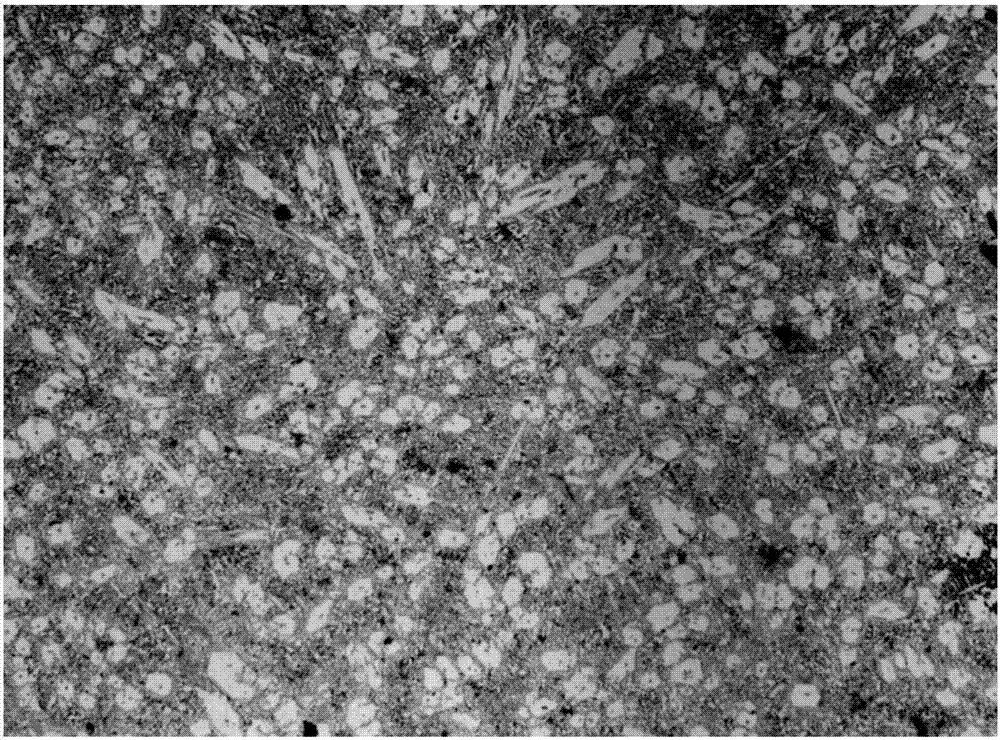

A heat-resistant and wear-resistant flux-cored welding wire

ActiveCN105945456BNon-spontaneous nucleationOptimize the reasonable rangeWelding/cutting media/materialsSoldering mediaRare-earth elementHeat flux

The invention belongs to the technical field of metal surfacing materials and particularly relates to a heat-resisting and wear-resisting flux-cored wire. The heat-resisting and wear-resisting flux-cored wire is formed by wrapping a low-carbon cold-rolled steel strip on flux core powder. The flux core powder comprises, by weight, 0.25-1.0% of graphene, 40-45% of chromium metal, 5-9% of electrode graphite, 2-4% of marble, 1-3% of chromium carbide, 1-4% of electrolytic manganese metal, 3-6% of silicon iron, 4-6% of molybdenum, 6-10% of nickel, 2-4% of ferro-boron, 0.5-3% of niobium, 0.5-3.0% of tungsten, 0.5-1% of rare earth, and the balance FHY100.25 reduced iron powder. According to the heat-resisting and wear-resisting flux-cored wire, weld metal structures are refined and homogenized by adding components such as graphene, rare earth elements and chromium carbide into the flux core powder and optimizing the reasonable range of components, and the high-temperature tempering stability of surfacing metal is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Method for preparing heat-resistant and wear-resistant alloy coatings on surfaces of hot rolling plate fine rolling conveying rollers

ActiveCN102453895BImprove heat and wear resistanceHigh surface hardnessMolten spray coatingLaser beam welding apparatusNumerical controlMachined surface

The invention relates to a method for preparing heat-resistant and wear-resistant alloy coatings on the surfaces of hot rolling plate fine rolling conveying rollers. The method is characterized by comprising the following steps that: 1) the conveying rollers are subjected to surface pre-treatment; 2) alloy powder is selected, and an automatic powder conveyor is regulated; 3) light beams are regulated, a 10*1mm wide band integral lens is adopted, and in addition, the off-focus value is regulated so that the focused laser facula is rectangular; 4) a DL-HL-T5000 type CO2 laser is adopted for wear-resistant anti-corrosion coating laser cladding, a work table is a SIMENS numerical control laser processing machine, a synchronous powder conveyor is adopted for automatically conveying the alloy powder into a laser molten pool, high-power focus laser beams and an automatic powder conveying head are fed in the axial direction of the conveying rollers, the rotation is carried out at the set rotating speed, and uniform and compact laser cladding layers are formed on the processing surfaces of the conveying rollers; and 5) flaw detection is carried out after the cladding. The surface hardness, the wear resistance and the contact fatigue resistance capability of the conveying rollers can be obviously improved through reinforcing layers formed through the laser cladding.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

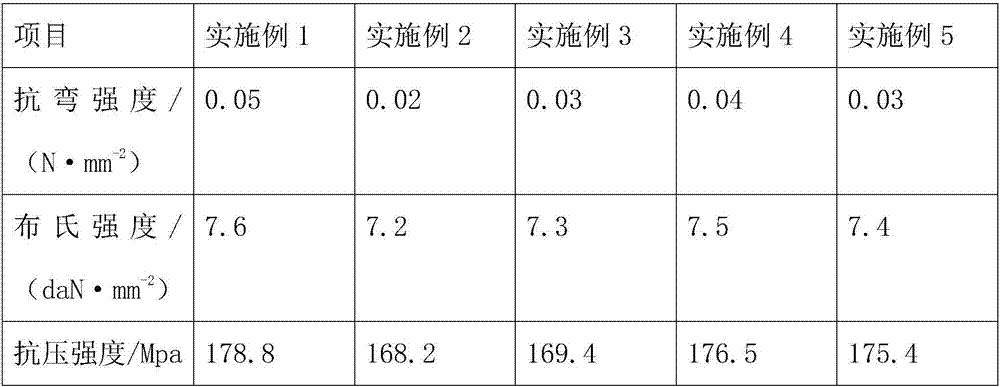

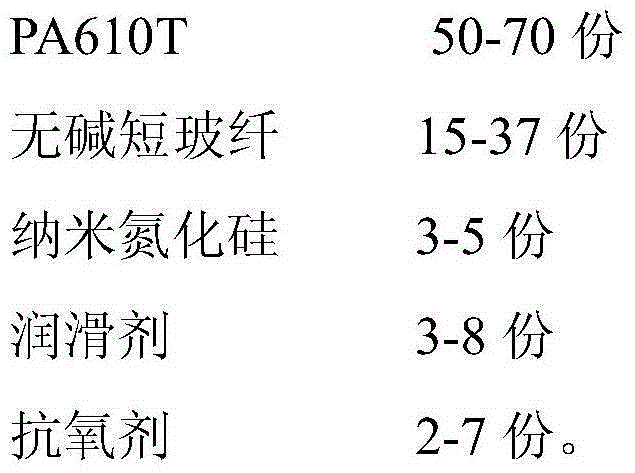

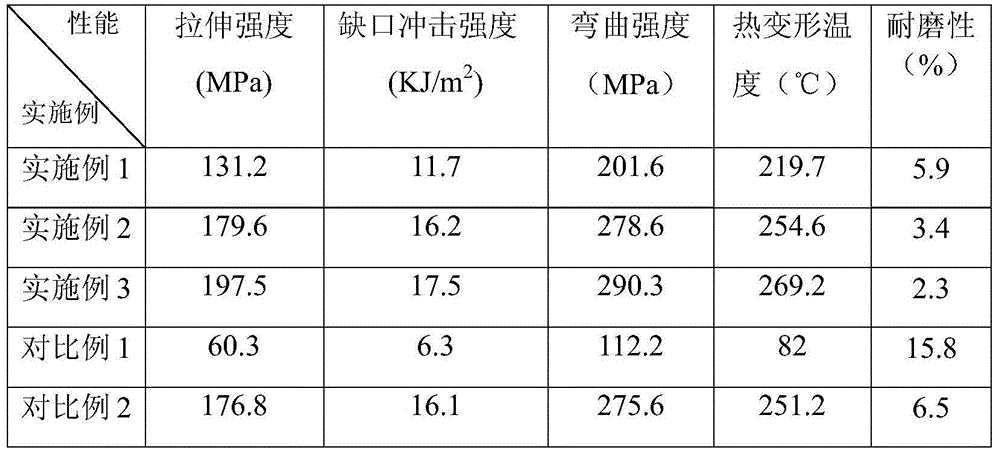

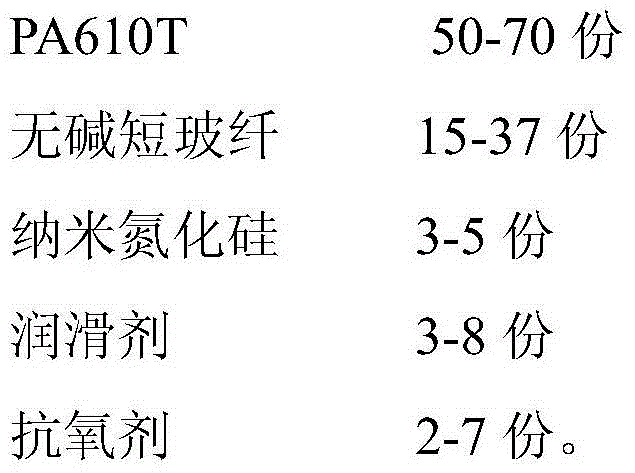

Heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition and preparation method thereof

The invention relates to a heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition and a preparation method thereof. The composition is prepared from, by weight, 50 to 70 parts of PA610T, 15 to 37 parts of alkali-free short glass fiber, 3 to 5 parts of nanometer silicon nitride, 3 to 8 parts of a lubricant and 2 to 7 parts of an anti-oxidant. The preparation method comprises the following steps: weighing nylon, nanometer silicon nitride, the anti-oxidant and the lubricant according to the above-mentioned weight parts, carrying out uniformly mixing, pouring an obtained mixture into a hopper of an extruder and adding the alkali-free short glass fiber into a side feed inlet; starting the extruder and a vacuum pump and carrying out extrusion and granulation via the double screw-extruder so as to obtain am alkali-free short glass fiber-reinforced nylon PA610T composition; and drying the composition in a baking oven with a temperature of 90 to 110 DEG C for 2 to 6 h so as to obtain the heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition for subsequent usage. Compared with the prior art, the invention has the following advantages: the preparation method is simple and stable; the alkali-free short glass fiber and auxiliary agents are uniformly dispersed in nylon resin; compatibility of the short glass fiber and nylon resin is good; and the obtained composition has ideal mechanical properties and excellent heatproof and wear-resistant performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A kind of heat-resistant and wear-resistant nano anti-corrosion coating and preparation method thereof

ActiveCN106243908BReduce frictionImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyALUMINUM STEARATES

The invention discloses a heat-resistant and wear-resistant nano anticorrosion coating and a preparation method thereof. The coating is composed of an A component, a B component, a C component, a D component and an E component; the A component is a substrate mixture prepared from organosilicone phenolic resin dispersion liquid and epoxy resin dispersion liquid, the B component is an auxiliary mixture prepared from calcium carbonate, ceramic powder, bentonite, zinc borate, mica powder, a defoaming agent and talcum powder, the C component is a heat-resistant mixture prepared from nano-aluminum powder, nano-aluminum stearate and nano-titanium nitride, the D component is a wear-resistant mixture prepared from graphite powder, polyphenylene sulfide and polyether-ether-ketone, and the E component is a pigment which can be selected from a green pigment or a blue pigment or a black pigment or a gray pigment or a red pigment or a yellow pigment or a purple pigment or an orange pigment. The invention further discloses the preparation method of the heat-resistant and wear-resistant nano anticorrosion coating. The heat-resistant and wear-resistant nano anticorrosion coating has the anticorrosion performance, the heat resistance and the wear resistance and is simple in preparation method and high in using stability.

Owner:西安鸿钧睿泽新材料科技有限公司

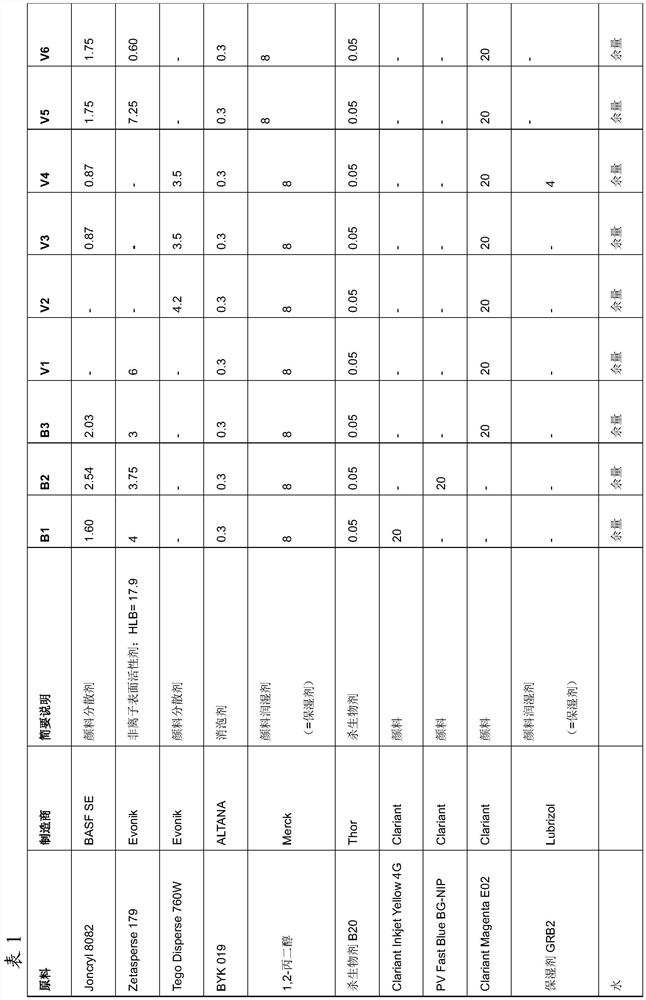

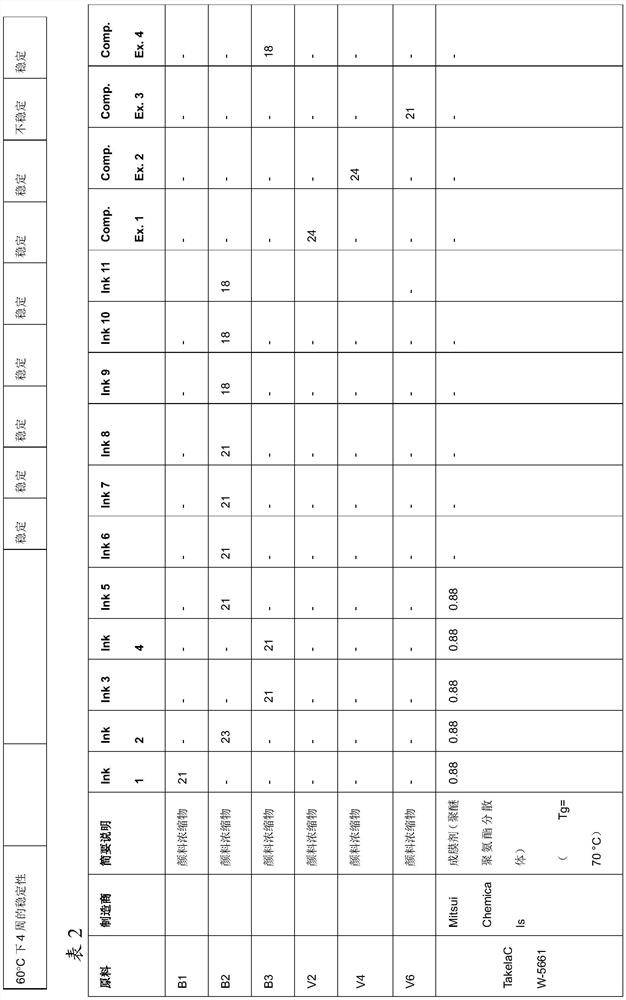

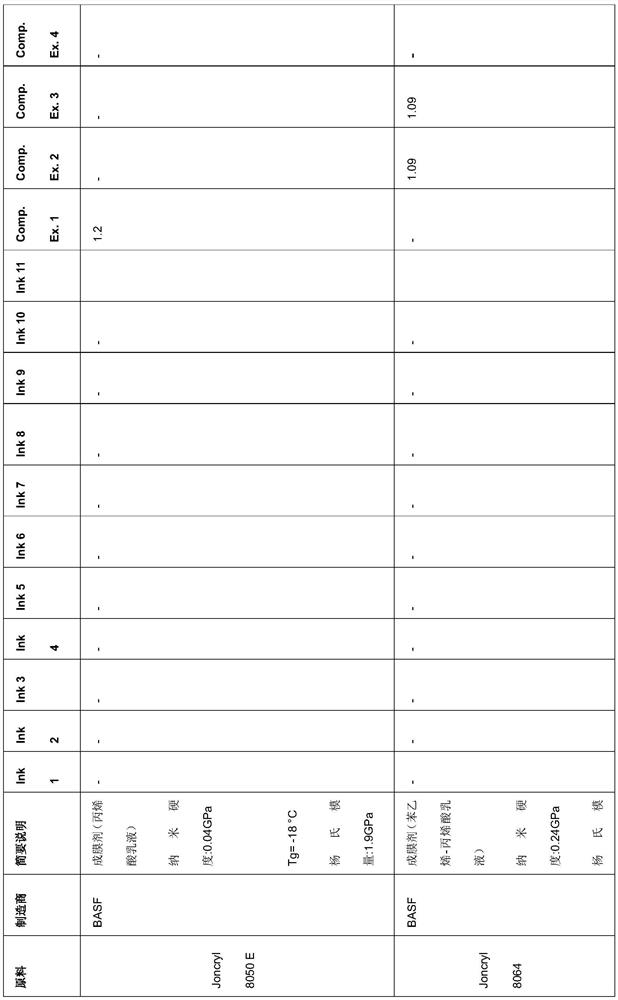

Aqueous inkjet inks and uses thereof

PendingCN114746519AImprove heat and wear resistanceEmission reductionDuplicating/marking methodsPaper coatingCardboardPolymer science

The present invention provides an aqueous ink comprising one or more film formers wherein the assembly film concentration in the aqueous ink is from 0.1 to 30 wt.%, and optionally one or more emulsifiers, preferably wherein the total emulsifier concentration in the aqueous ink is from 0.1 to 10 wt.%. The one or more emulsifiers, if any, are fatty acid esters of polyalkoxylated sorbitan, and / or the one or more film formers satisfy at least one of the following properties: a Young's modulus of at least 2 GPa, and a nanohardness of at least 0.08 GPa. Also provided is the use thereof for inkjet printing, preferably on corrugated cardboards or on liners used for producing corrugated cardboards.

Owner:TIGERWERK LACK & FARBENFAB

Preparation method of heat-resistant and wear-resistant alloy coating on surface of wrapper roll of hot rolling sheet

ActiveCN102453899BImprove heat and wear resistanceHigh surface hardnessMetallic material coating processesNumerical controlLaser processing

Owner:唐山大陆激光工程技术有限公司

Capacitor aluminum shell high-temperature-resistant paint

InactiveCN106519958AImprove curing effectImprove heat and wear resistanceFireproof paintsPolyamide coatingsCapacitanceSodium phosphates

The invention discloses a capacitor aluminum shell high-temperature-resistant paint which is prepared from a polyamide resin, polyvinyl alcohol, polymethyl methacrylate, diatomite, a phenolic resin, silicone oil, aluminum silicate, olive oil, sodium phosphate, wheat hull ash and a corn straw extract. After being sprayed on the capacitor aluminum shell surface, the capacitor aluminum shell paint has favorable curing effect, can effectively protect the capacitor, has favorable heat resistance and wear resistance, and can effectively achieve the heat radiation effect under the synergistic actions of the corn straw extract and wheat hull ash.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

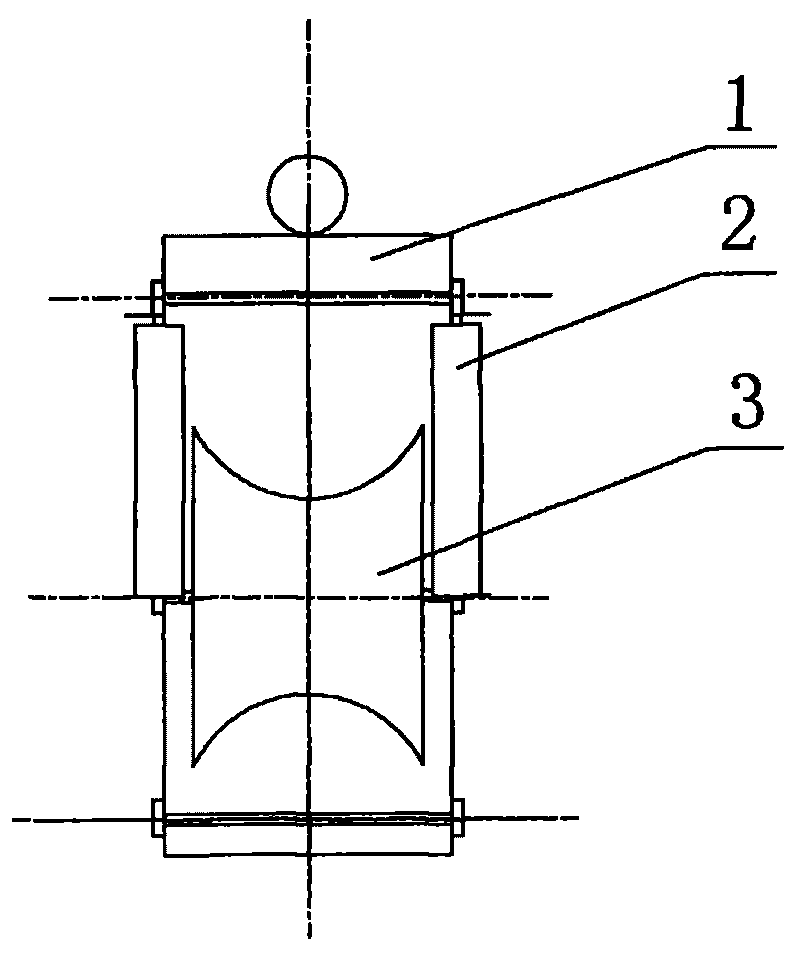

Heatproof wearable wet sleeve

InactiveCN106150742AImprove heat and wear resistanceImprove the effect of heat and wear resistanceCylinder headsCylindersPistonEngineering

The invention provides a heatproof wearable wet sleeve which comprises a water tank sleeve and a main body, wherein the main body is in nested connection with the water tank sleeve; a first flange is arranged at the upper end of the main body; a plurality of second flanges are arranged on a side wall of the main body; a heatproof wearable layer is arranged on the inner wall of the main body. Due to the design, the heatproof wearable effect of the inner wall of the sleeve is improved and the cooling dissipating effect of the sleeve and a piston is also enhanced.

Owner:扬州神驰新材料科技有限公司

Processing Technology of High Wear-resistant Aluminum Alloy Foam Die Casting

The invention discloses a processing technology for a high-abrasion-resistance aluminium alloy foaming mould casting, and the processing technology comprises the following four steps of: burdening, smelting, casting and carrying out heat treatment. According to the processing technology disclosed by the invention, appropriate amounts of rare earth elements such as Y, Pr and Nd are added in aluminium alloy, the content of hydrogen in the aluminium alloy is reduced, and the plasticity, heat resistance, abrasion resistance and high temperature strength of the aluminium alloy are improved. An aluminium alloy refrigerator foaming mould casting processed by adopting the processing technology disclosed by the invention has the advantages of good mechanical properties, high strength, good heat resisting property, good usability, good internal structure compactness, no pore or peeling, high abrasion resistance, high oxidation resistance, low expansion coefficient and the like.

Owner:CHUZHOU DIMENGDE MOLD MFG

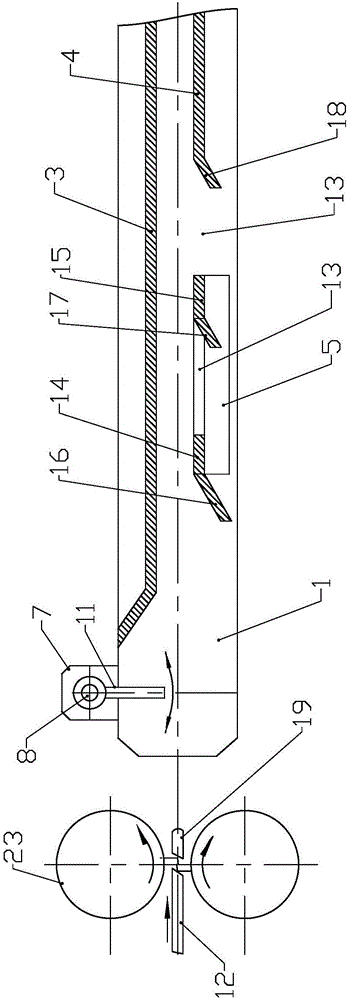

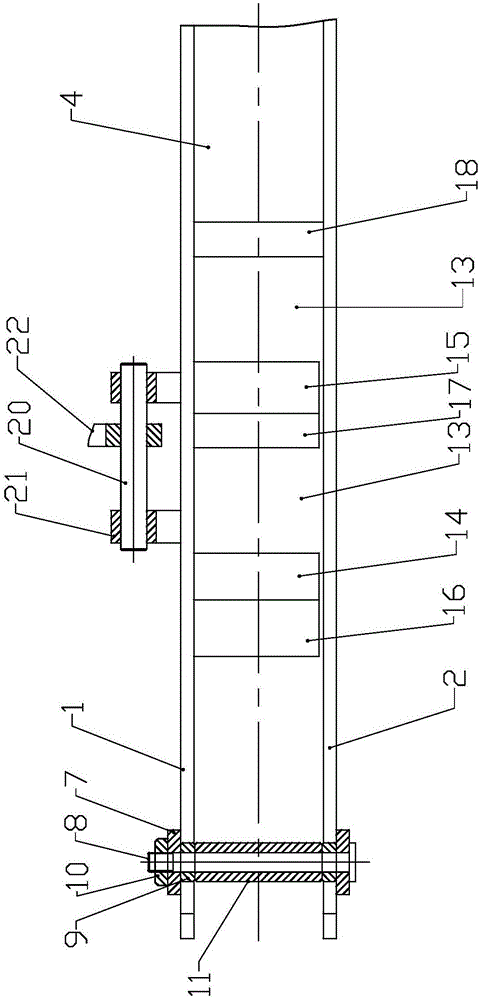

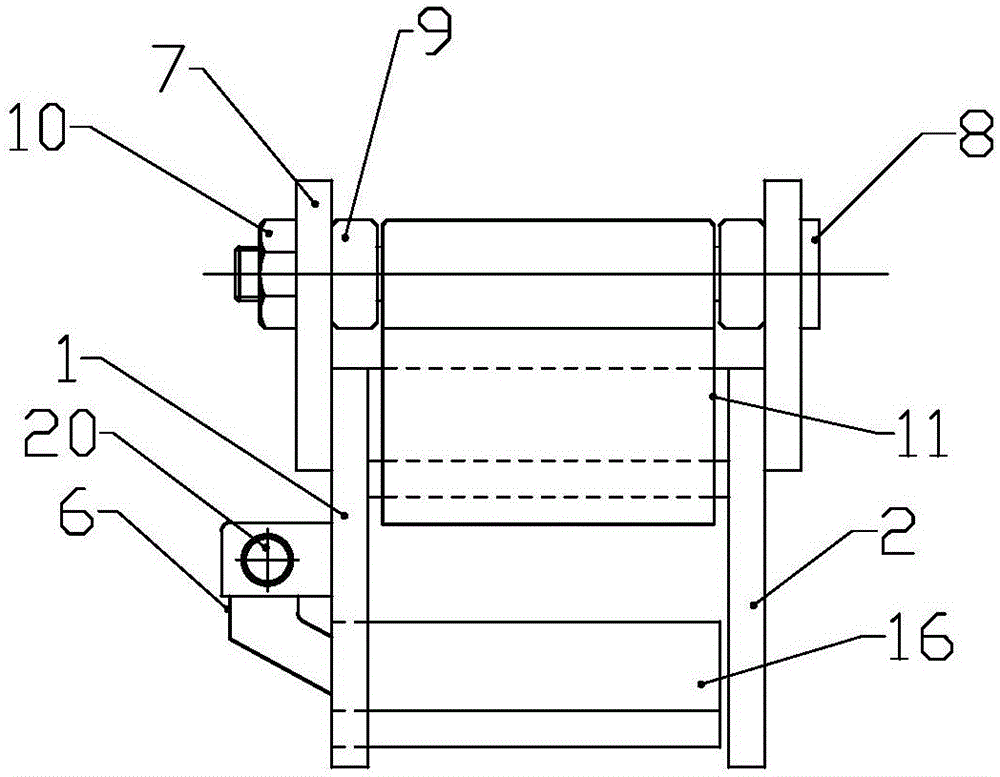

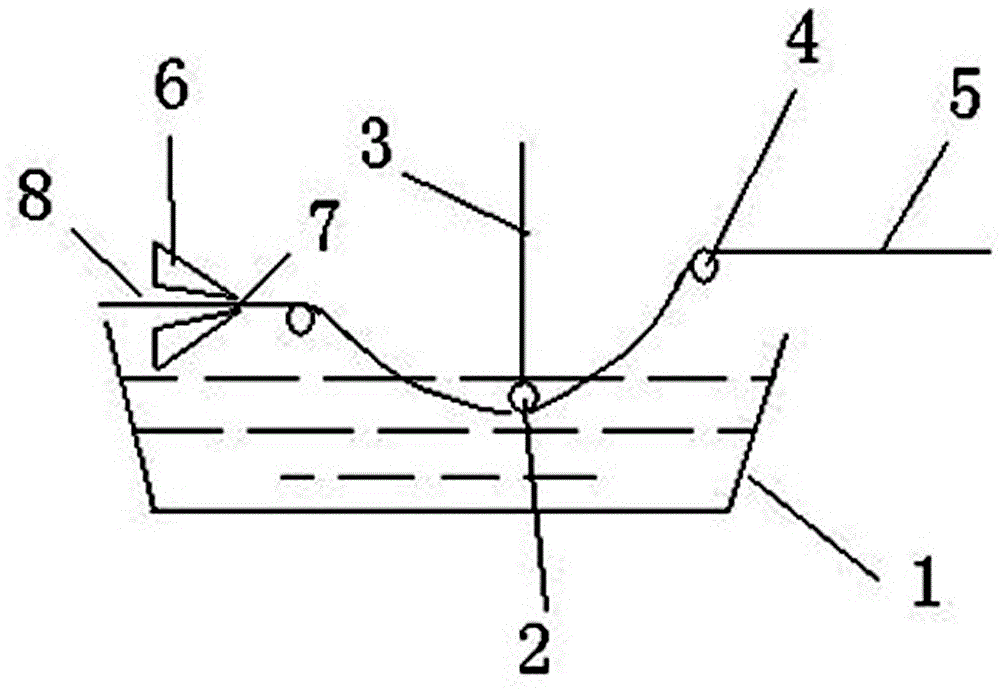

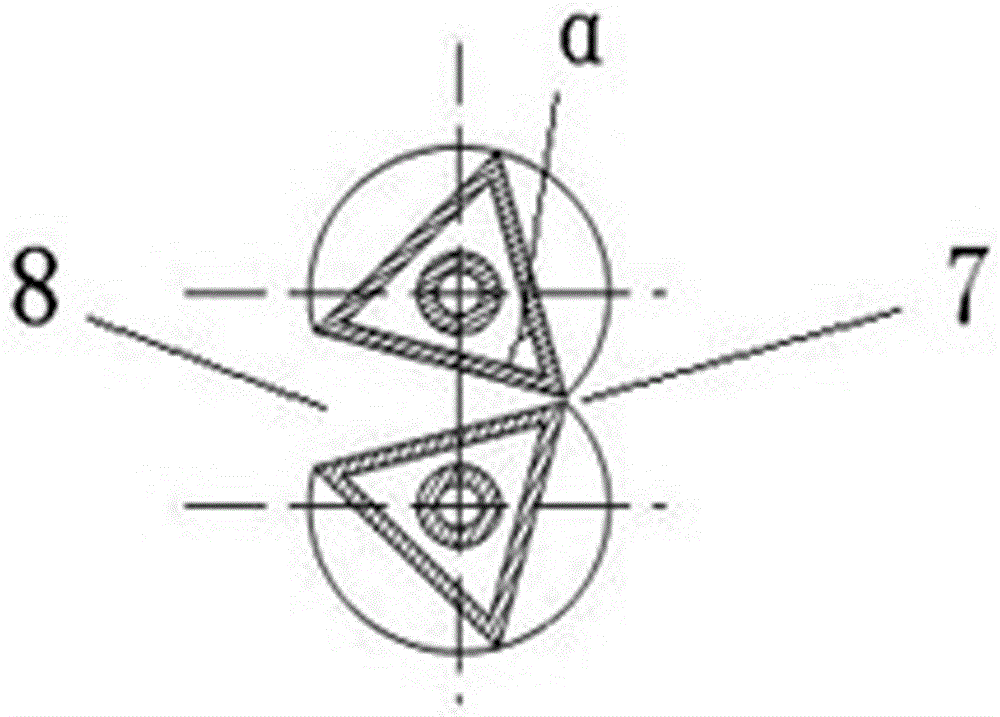

Slot running device after cutting head of small bar and flying shear

InactiveCN103962472BEfficient collectionReliable collectionMetal-working feeding devicesPositioning devicesMechanical engineering

The invention discloses a rear runner device of a flying crop shear for a small bar material and belongs to the production equipment of the small bar material. The rear runner device comprises a rear runner mechanism including a left-side protection plate, a right-side protection plate, an upper protection plate, a fixed base plate, a movable overturning plate and a movable overturning plate driving mechanism, wherein a blank head baffling device is arranged on the front side of the upper protection plate and comprises support plates, a shaft pin, a spacer bush, a locking unit and a baffle, and the baffle is arranged on the shaft pin; a leaking groove is formed in the middle of the movable overturning plate to divide the movable overturning plate into a front movable overturning plate and a rear movable overturning plate, and a front overturning plate baffle and a rear overturning plate baffle are respectively arranged on the front sides of the front movable overturning plate and the rear movable overturning plate; a leaking groove is further formed between the fixed base plate and the movable overturning plate, and a base plate guiding plate is arranged on the front side of the fixed base plate. The rear runner device has the characteristics that sheared blank heads can effectively fall into a blank head collection pit, the obstruction caused after the sheared blank heads of rolled blanks fly into a runner is avoided, and a 'steel accumulation accident' is further avoided.

Owner:JIGANG GRP

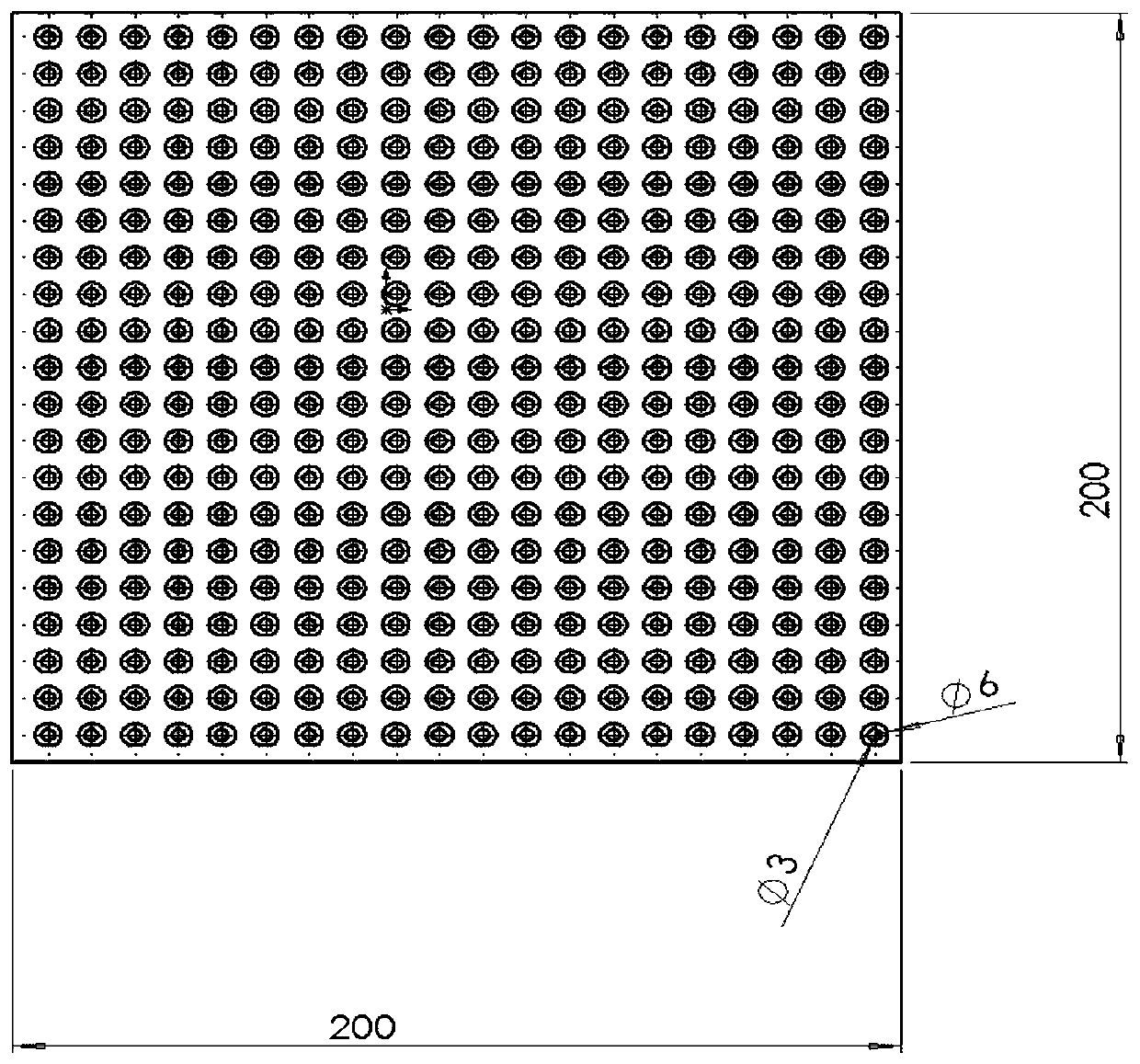

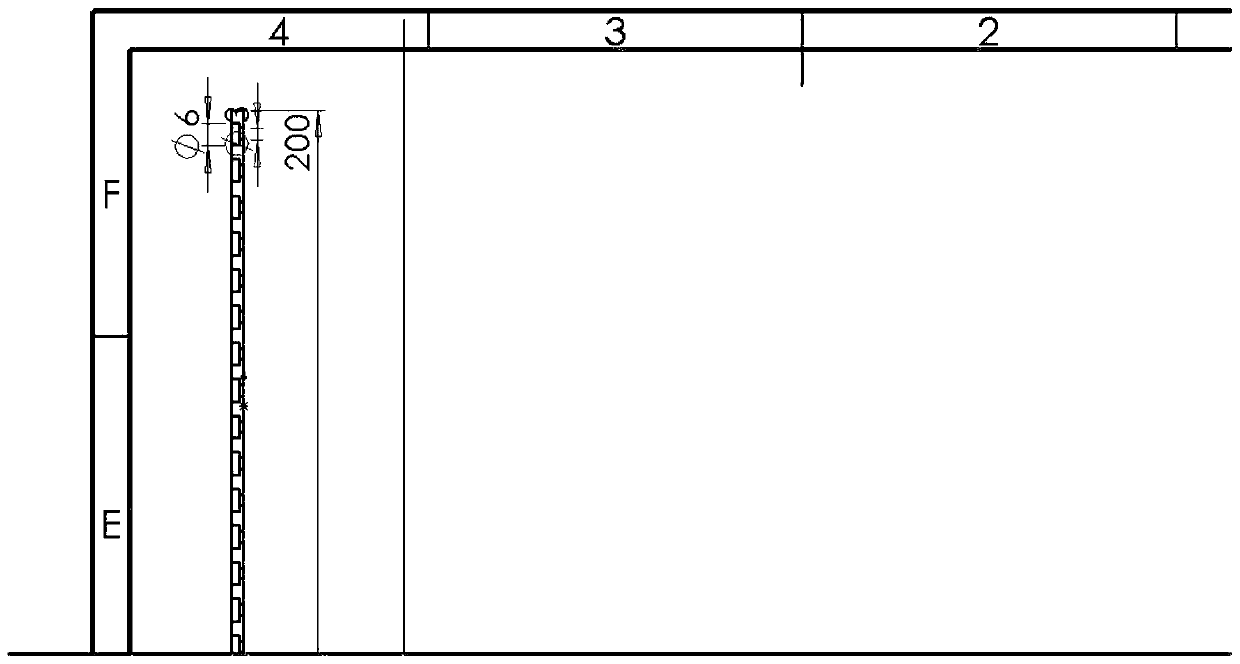

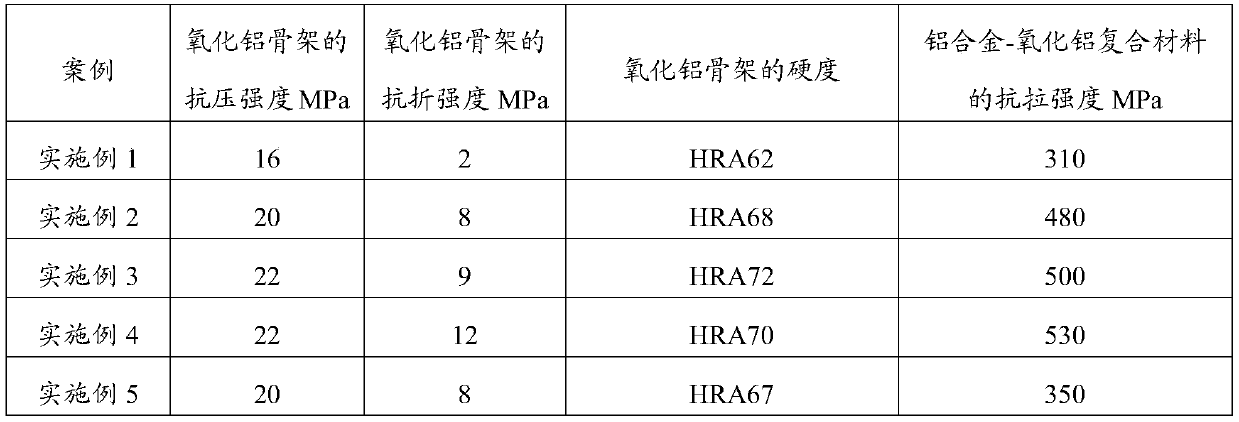

A kind of aluminum alloy-alumina composite material and its preparation method and application

ActiveCN110358944BMature technologyDrilling is quick and easyBraking discsHeat resistanceOxide composite

The invention belongs to the technical field of composite materials, and particularly relates to an aluminum alloy-aluminum oxide composite material as well as a preparation method and application thereof. An aluminum oxide framework is prepared by adopting a mould pressing method or a tape casting method, the yield of the aluminum oxide framework reaches 95%, and meanwhile, the production efficiency and the yield are improved. The hardness of the prepared aluminum oxide framework reaches HRA 70, when the aluminum alloy-aluminum oxide composite material is used for a brake disc with a frictionpair, the aluminum oxide framework cannot cause serious damage to the friction pair due to excessively high hardness, and the service life of the brake disc and the friction pair is prolonged. The aluminum alloy-aluminum oxide composite material is prepared by combining the good toughness of an aluminum alloy and the heat resistance and wear resistance of aluminum oxide, the wear resistance of the aluminum alloy is improved, and when the aluminum alloy-aluminum oxide composite material is used for the friction pair, the wear amount is less than 30 mg / MJ.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

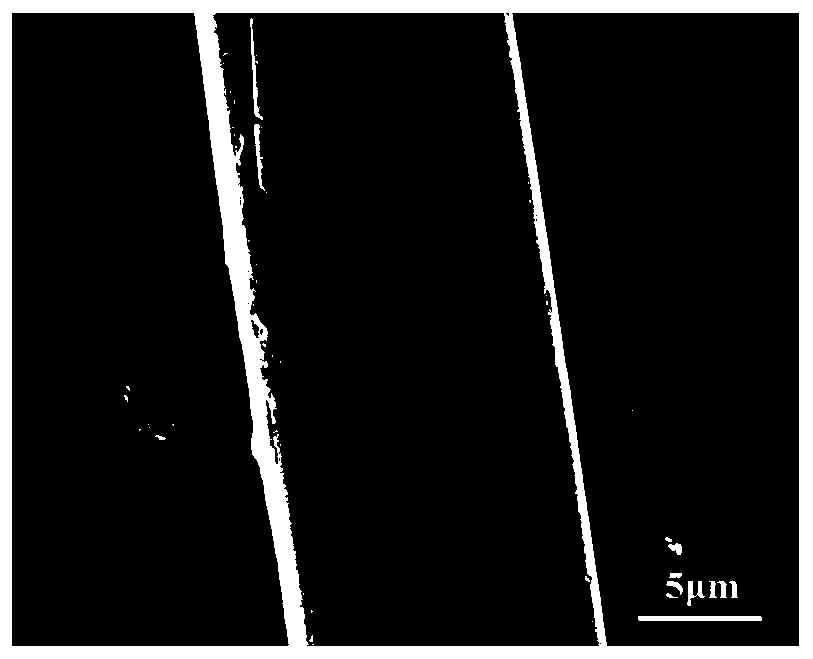

A modification method of para-aramid chopped fiber

ActiveCN106637953BImprove inert surfacesImprove heat and wear resistanceFibre typesWear resistantAmmonium hydroxide

The invention discloses a modification method of p-aramid fiber chopped fiber. A mixed acid solution is used for performing coarsening pretreatment on the cleaned p-aramid fiber chopped fiber; a sol-gel method is used for performing nanometer SiO2 modification on the surface of the p-aramid fiber chopped fiber subjected to pretreatment to obtain the modified p-aramid fiber chopped fiber. The modification method of the p-aramid fiber chopped fiber has the advantages that the sol-gel method is used; tetraethoxysilane is used as a precursor; the tetraethoxysilane is hydrolyzed by ammonium hydroxide in an ethanol medium; the nanometer SiO2 particles are subjected to in situ synthesis on the fiber surface; the smooth insert surface without active groups of the fiber is improved. The nanometer SiO2 synthesized on the surface of the fiber has good heat-resistant and wear-resistant performance, and can be used as a composite material enhancing body for improving the high-temperature-resistant friction-resistant and abrasion-resistant performance of the material.

Owner:SHAANXI UNIV OF SCI & TECH +1

Preparation method of anti-aging agent for powder coating

The invention discloses a preparation method of an anti-aging agent for a powder coating, and relates to the technical field of powder coating assistants. The preparation method comprises the following steps: (1) preparing dispersion liquid; (2) preparing modified liquid; (3) preparing premixed liquid; (4) mixing the premixed liquid and the modified liquid for reaction, and drying. The invention provides the preparation method of the anti-aging agent for the powder coating, wherein the prepared anti-aging agent has a good curing effect, good heat resistance and good wear-resisting property after being applied to the powder coating; by adding the anti-aging agent prepared by the method, dispersibility and fluidity of a powder coating mixture system are improved, compatibility with components in the powder coating system is good, melting time after mixing is short, and anti-aging property of a powder coating film can be obviously improved. Through high compatibility in the powder coating, hardness of the coating film can be greatly improved, and denseness of the coating can be improved, so that scratch resistance of the coating film is greatly improved.

Owner:安徽迈高化工科技有限公司

A modified asphalt coil forming thickness control device to prevent tire base from being scraped

ActiveCN103506252BAvoid strong pullingAvoid scratchesLiquid surface applicatorsCoatingsHeat resistanceEngineering

The invention discloses a modified asphalt coiled material forming and thickness control device capable of preventing tire bases from being broken by blowing, The forming and thickness control device comprises two thickness-adjusting devices which are arranged in an up-and-down opposite mode. The forming and thickness control device is characterized in that the two thickness-adjusting devices are both of a wedged structure, the front ends of the two thickness-adjusting devices are arranged oppositely to each other, a first gap is arranged between the two thickness-adjusting devices, the first gap is the input end of the forming and thickness control device, a second gap is arranged between the rear ends of the two thickness-adjusting devices, the second gap is the output end of the forming and thickness control device, and the first gap is less than the second gap. Due to the wedged structures, a tire-containing coiled material after being provided with a coating material is smoother, and more uniform in thickness. A thickness-adjusting roller can be made of engineering ceramics, so that the heat resistance and wear resistance of the device are better. Therefore, the forming and thickness control device disclosed by the invention has the advantages that the device can prevent tire bases from being broken by blowing; the tire-containing coiled material after being provided with the coating material is smoother, and more uniform in thickness.

Owner:湖南信提环保装备技术咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com