Tooth roller and grate of single-tooth roller crusher

A technology of roller crusher and crushing teeth, which is applied in the field of single-toothed roller crusher toothed rollers and grating bars, which can solve the problems of increased production and maintenance costs for users, non-heat-resistant and wear-resistant parts, and poor water cooling effect, etc., to achieve Good cooling effect, good heat resistance and wear resistance, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

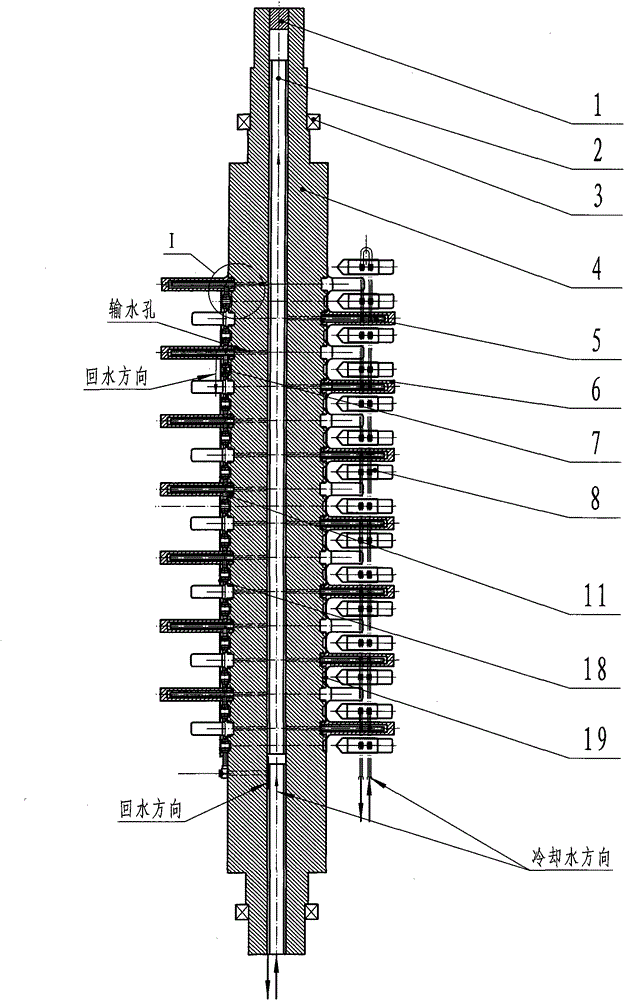

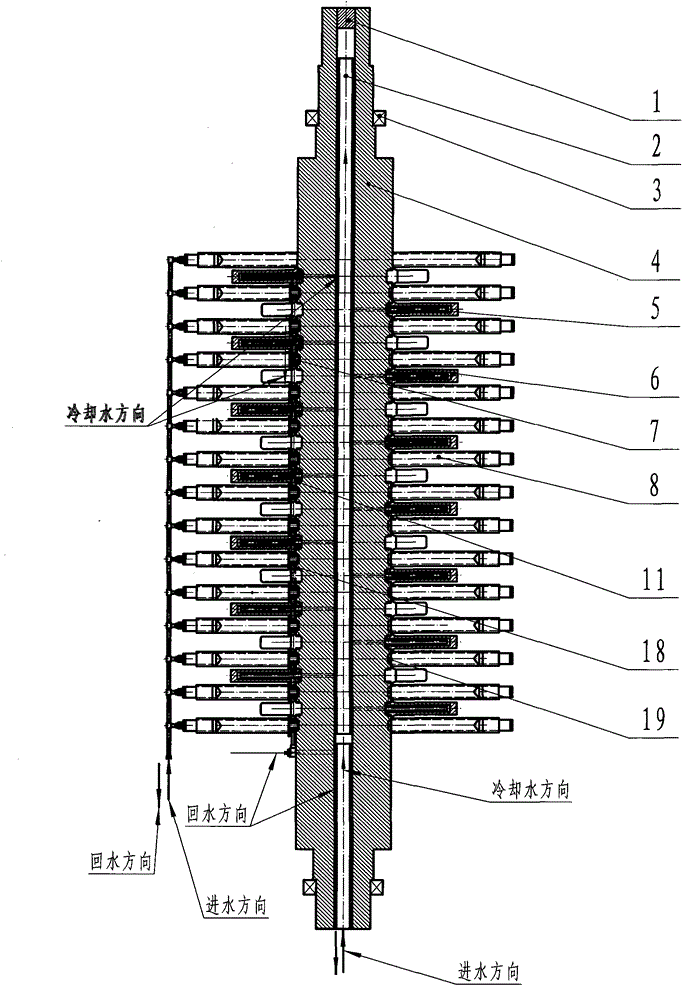

[0054] Example 1: Full water-cooled single-toothed roller crusher toothed roller and grate bar

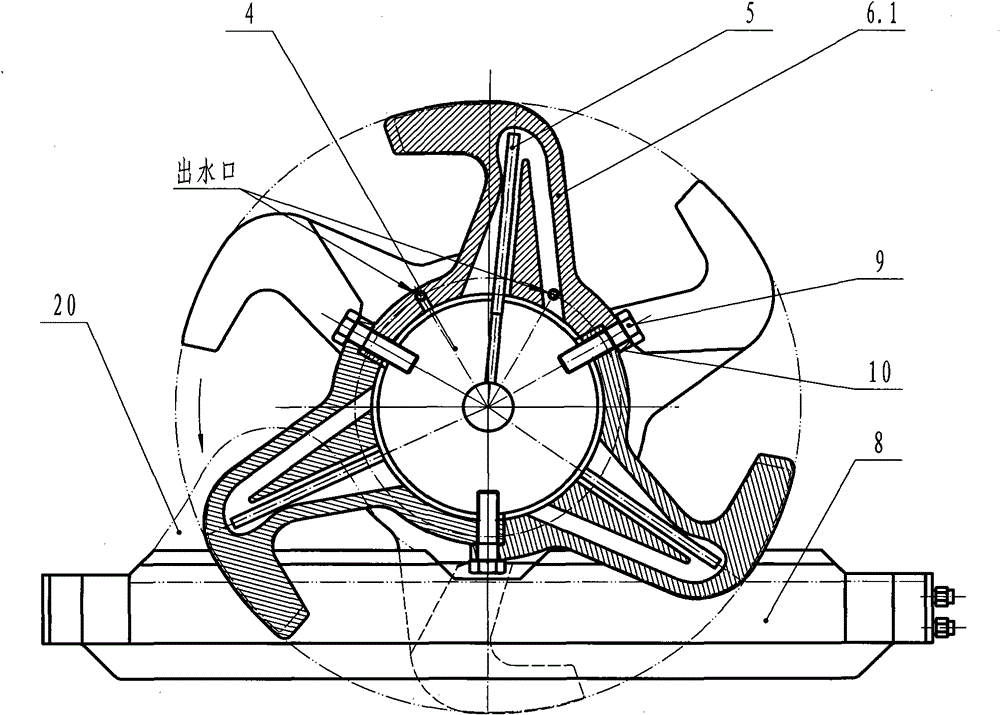

[0055] figure 1 , 2 , 3 is the assembly diagram of the toothed roller and the grating bar of the full water-cooled single-toothed roller crusher. Among the figures, the toothed roller is composed of 14 water-cooled crushing toothed rings 6.1 interlaced by 60 degrees and embedded on the water-cooled toothed roller shaft 4.1. The broken grating plate assembly is composed of 15 water-cooled grating bars 8.1. When the toothed roller presses image 3 When the direction indicated by the arrow turns counterclockwise, the sintered material 20 falling on the grating plate will be broken into materials with a certain particle size. One side of the cooling water is connected to the rotary joint water inlet pipe 2 at the middle of the toothed roller shaft and enters the central waterway of the toothed roller shaft to cool the toothed roller shaft. One end of the central waterway of the toot...

Embodiment 2

[0062] Example 2: Semi-water-cooled single-toothed roller crusher toothed roller and grate bar

[0063] Semi-water-cooled single-toothed roller crusher toothed rollers and grating bars are still in production, and there is still a good market demand, especially in small and medium-sized sinter production enterprises.

[0064] Figure 26 , 27 , 28 is the structural diagram of the toothed roller of the semi-water-cooled single-toothed roller crusher. In the figure, the non-water-cooled crushing gear ring 6.3 is a three-toothed claw that bites each other in sequence, and is fastened by the fastening bolt 9, and is embedded on the toothed roller shaft 4.2. Broken gear rings 6..3 can be formed by one-time casting, and the trapezoidal surface of the inlaid part can be turned and drilled on the machine tool at one time, and then separated into three-tooth claws by the wire cutting machine tool, the processing is very simple. The tooth crown of the claw part is Figure 28 As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com