Concentrated aqueous dispersion of fluorine-containing polymer as well as preparation method and application of concentrated aqueous dispersion

A water-based dispersion, polymer technology, used in abrasion-resistant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of poor biodegradability, unfriendly environment, limited wide application, etc., and achieve good stability and good gloss. The effect of low viscosity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

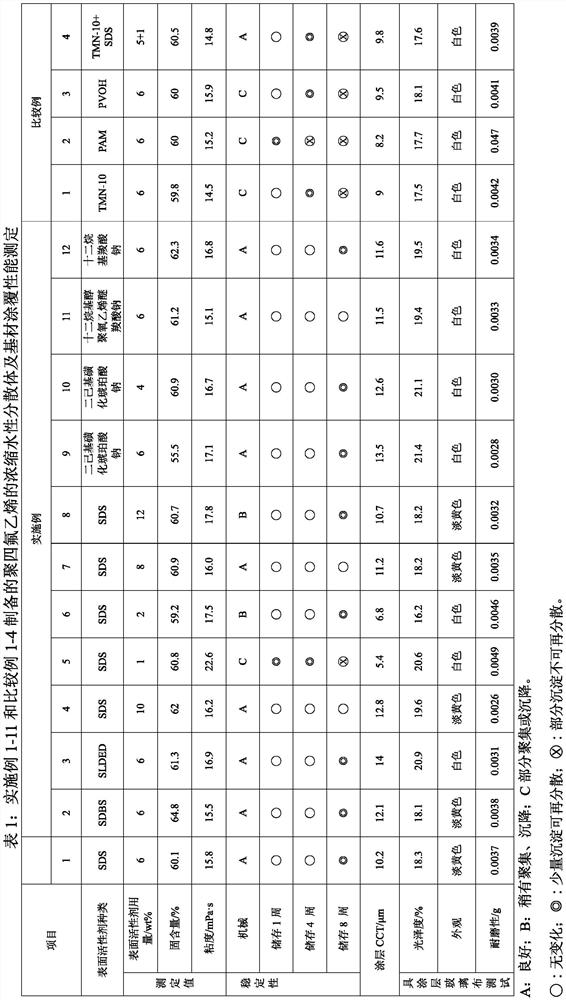

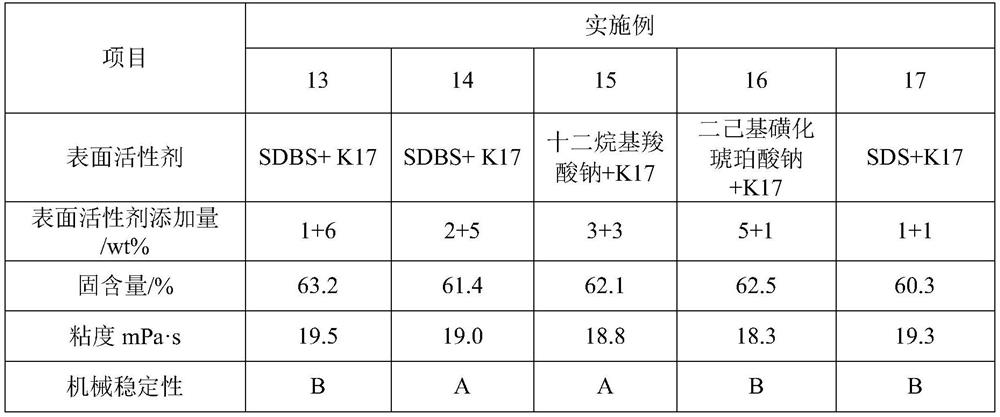

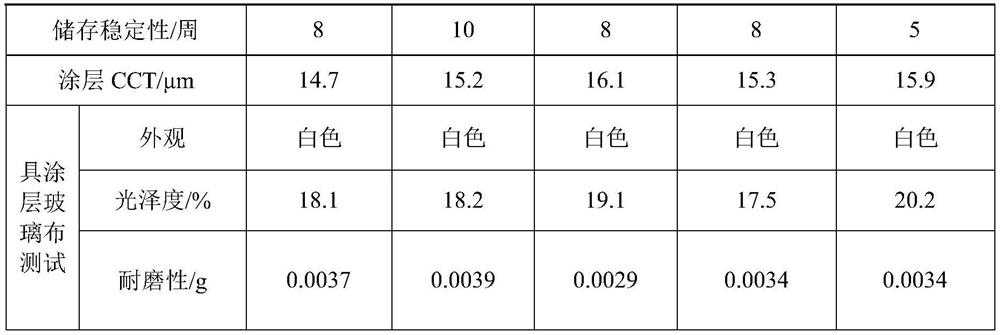

Examples

Embodiment 1

[0082] In a 5L stainless steel high-pressure reactor equipped with a jacket and a horizontal stirrer, add 3000g of deionized water and 80g of paraffin, heat the contents of the reactor to 70°C, and vacuumize the reactor, replace it with nitrogen, and then use tetrafluoroethylene (TFE) purge. Add 0.02 g of polymerization initiator ammonium persulfate, 3 g of fluorine-containing emulsifier (sodium perfluorohexyl acetate), control the reaction pressure to 2.5 MPa, and continuously feed TFE through the compressor. By means of emulsion polymerization, a starting aqueous dispersion of polytetrafluoroethylene particles is prepared. The solid content of this dispersion is about 30% by weight, and the average particle size of the polytetrafluoroethylene particles is 250 nm.

[0083] Get the initial aqueous dispersion of 2kg polytetrafluoroethylene particles (wherein contain the sodium perfluorohexyl acetate of about 0.2wt% based on the weight of polytetrafluoroethylene particles), add...

Embodiment 2

[0085] According to the steps in Example 1, the difference is that the sodium dodecylbenzenesulfonate anionic surfactant represented by SDBS replaces the SDS in Example 1, and the consumption is 6 wt%, and vacuum concentration is carried out, and the obtained concentrated aqueous dispersion The solid content of the body is about 64.8wt%. The performance test results are shown in Table 1 below.

Embodiment 3

[0087] Carry out according to the step in embodiment 1, difference is that the sodium dodecyl diphenyl ether disulfonate anionic surfactant represented in the aqueous solution of 45% SLDED replaces the SDS among the embodiment 1, consumption is 6wt% (in SLDED dry basis), carry out vacuum concentration, the solid content of gained concentrated aqueous dispersion is about 61.3%. The performance test results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com