Aqueous inkjet inks and uses thereof

A water-based ink and ink technology, applied in the field of inkjet printing ink, can solve the problems of wetting performance change, poor image quality, ink printing machine damage, etc., achieve and stabilize filtration performance, reduce VOC emissions, and good filtration performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

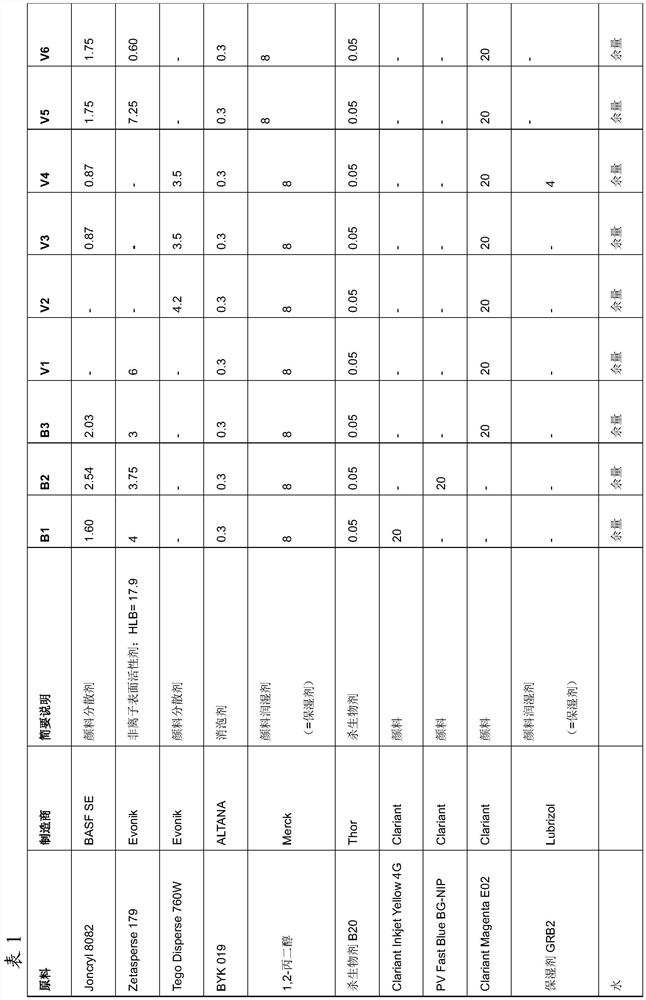

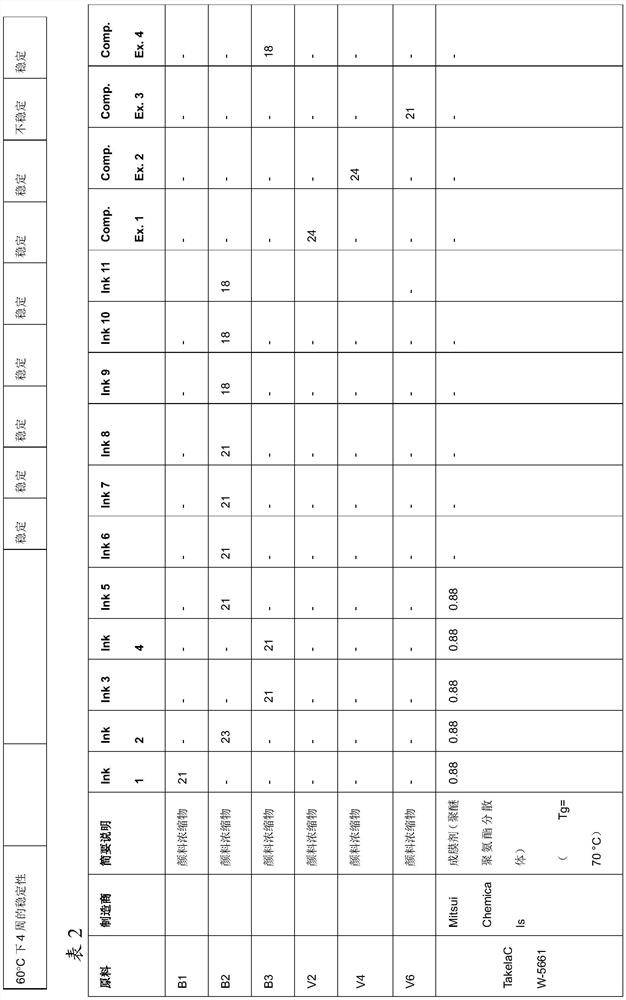

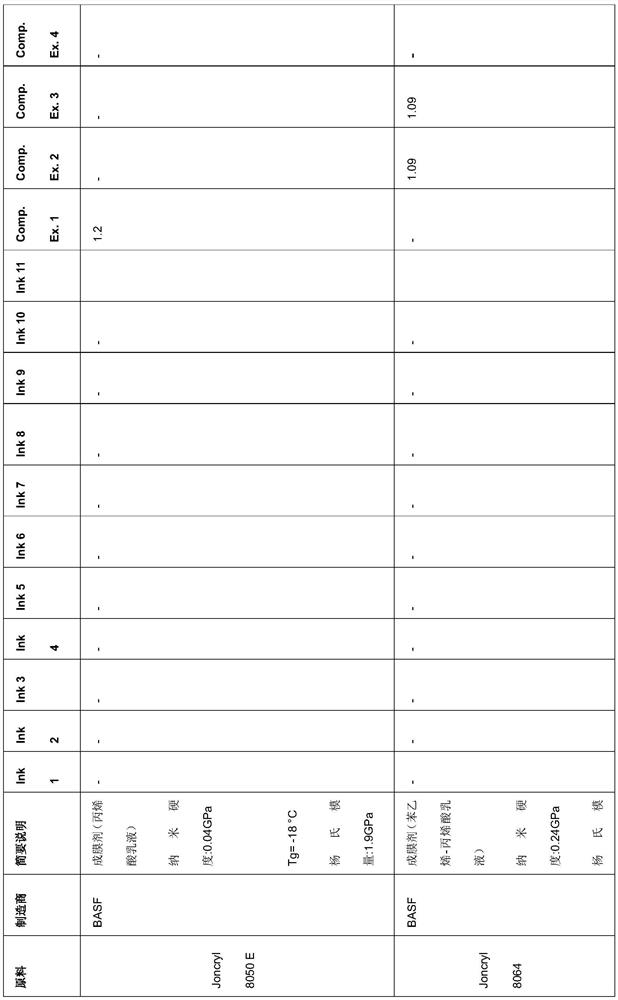

Method used

Image

Examples

Embodiment 1

[0181] Embodiment 1. a kind of water-based ink comprising aqueous pigment concentrate and pigment concentrate carrier liquid,

[0182] Wherein the water-based ink includes

[0183] - one or more film formers, wherein the total film former concentration in the aqueous ink is 0.1 to 10 wt.%,

[0184] - one or more emulsifiers, wherein the total emulsifier concentration in the aqueous ink is 0.1 to 10 wt.%,

[0185] wherein the one or more film formers satisfy at least one of the following properties:

[0186] i) a Young's modulus of at least 2 GPa, and

[0187] ii) Nanohardness of at least 0.08 GPa.

Embodiment 2

[0188] Embodiment 2. The water-based ink according to Embodiment 1, wherein the pigment concentrate carrier liquid further comprises one or more polyols and / or one or more glycol ethers having at least 2 hydroxyl groups , wherein their total concentration in the aqueous ink is 0.1 to 30 wt.%.

Embodiment 3

[0189] Embodiment 3. The water-based ink according to Embodiment 1 or 2, wherein the one or more film-forming agents include one or more film-forming agents selected from the group consisting of: polyurethane, polyacrylate, In particular polystyrene-(meth)acrylate or polystyrene (meth)acrylic copolymers, polyesters, polyamide-polyurethane copolymers, polyurethane-(meth)acrylates, polyamides, and mixtures thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com