A modification method of para-aramid chopped fiber

A technology of chopped fiber and para-aramid fiber, which is used in the paper industry, can solve the problems of poor wettability and poor interface adhesion, and achieve the effect of improving high temperature resistance, friction and wear resistance, interface bonding performance, and surface inertness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

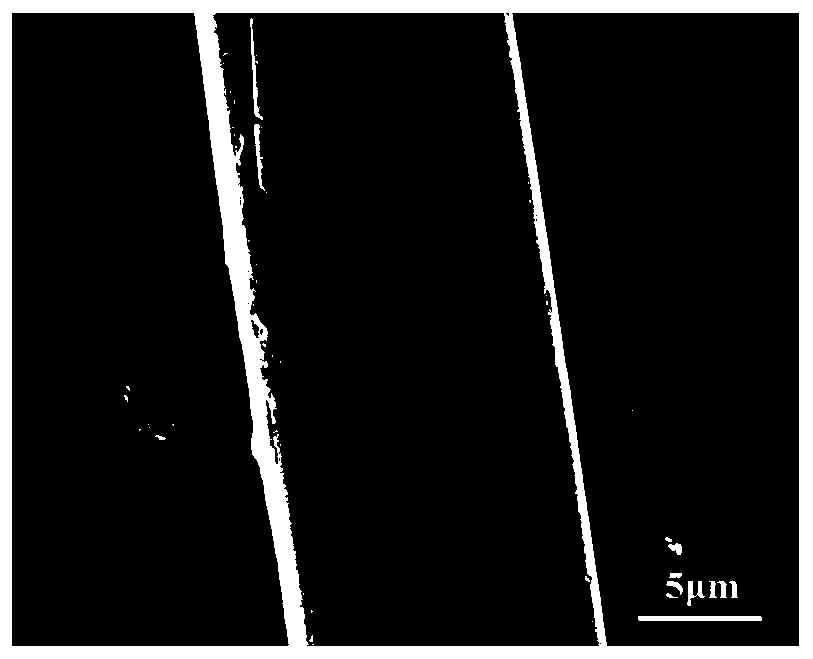

Image

Examples

Embodiment 1

[0029] (1) Fiber pretreatment: Add para-aramid chopped fibers into water, wash them with sodium dodecylbenzenesulfonate in a water bath at 50°C for 20 minutes, rinse them with distilled water, and dry them for later use. Prepare a mixed acid solution, which is a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1. Put the cleaned chopped fibers into the mixed acid solution, oxidize it, and then wash it with water and dry it for later use.

[0030] (2) Fiber modification process: ultrasonically disperse the oxidized chopped fibers in a stable and uniform mixed solution (the mixed solution is a mixture of absolute ethanol, deionized water and ammonia water at a volume ratio of 10:3:1) . Then, TEOS (tetraethyl orthosilicate) was added rapidly, and the resulting mixture was stirred at room temperature for 12 h to allow it to react.

[0031] (3) Fiber post-treatment: After the reaction is completed, the fiber mixture is vacuum-filte...

Embodiment 2

[0033] (1) Fiber pretreatment: p-aramid chopped fiber pretreatment: add p-aramid chopped fiber into water, wash with sodium dodecylbenzenesulfonate in a water bath at 60°C for 30 minutes, and then use Rinse with distilled water and dry for later use. Prepare a mixed acid solution, which is a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1. Put the cleaned chopped fibers into the mixed acid solution, oxidize it, and then wash it with water and dry it for later use.

[0034] (2) Fiber modification process: ultrasonically disperse the oxidized chopped fibers in a stable and uniform mixed solution (the mixed solution is a mixture of absolute ethanol, deionized water and ammonia water at a volume ratio of 10:3:1) . Then, TEOS (tetraethyl orthosilicate) was added rapidly, and the resulting mixture was stirred at room temperature for 13 h to allow it to react.

[0035] (3) Fiber post-treatment: After the reaction is completed, th...

Embodiment 3

[0037] (1) Fiber pretreatment: p-aramid chopped fiber pretreatment: add p-aramid chopped fiber into water, wash with sodium dodecylbenzenesulfonate in a water bath at 70°C for 40 minutes, and then wash with Rinse with distilled water and dry for later use. Prepare a mixed acid solution, which is a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1. Put the cleaned chopped fibers into the mixed acid solution, oxidize it, and then wash it with water and dry it for later use.

[0038] (2) Fiber modification process: ultrasonically disperse the oxidized chopped fibers in a stable and uniform mixed solution (the mixed solution is a mixture of absolute ethanol, deionized water and ammonia water at a volume ratio of 10:3:1) . Then, TEOS (tetraethyl orthosilicate) was added rapidly, and the resulting mixture was stirred at room temperature for 15 h to allow it to react.

[0039] (3) Fiber post-treatment: After the reaction is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com