Adhesive impregnation liquid and impregnation process for integrally weaving canvas

A dipping process and technology of dipping liquid, which is applied to the field of dipping liquid and impregnating process of integral woven canvas, can solve the problem of low strength of canvas skeleton material, low degree of impregnation between dipping liquid and canvas, complicated dipping process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 discloses a kind of impregnation process for integrally woven canvas, comprising the following preparation steps:

[0031] Step 1, preparation of base cloth

[0032] Polyester industrial yarn is used as the warp thread, nylon industrial yarn is used as the weft thread, and the warp thread and weft thread are woven by the method of integral weaving; among them, 8 warp threads are used, and the weft thread is divided into 4 rows, which are woven by double layers and woven into the base fabric. Standby; wherein, the warp thread density is 150 / 10cm, and the weft thread density is 80 / 10cm; the warp thread is 800D, and the weft thread is 500D. The twist of polyester industrial yarn is 20 twists / 10cm, and the twist of nylon industrial yarn is 10 twists / 10cm.

[0033] Step 2, preparation of dipping solution

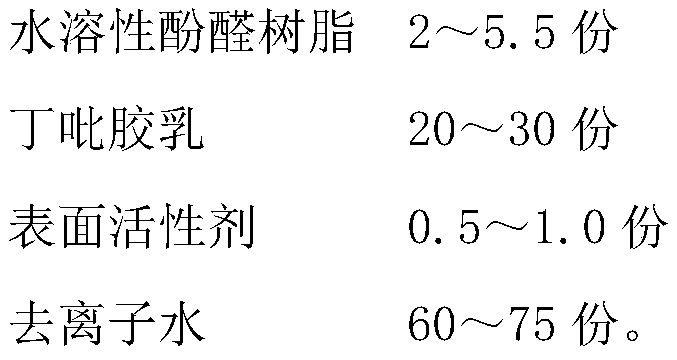

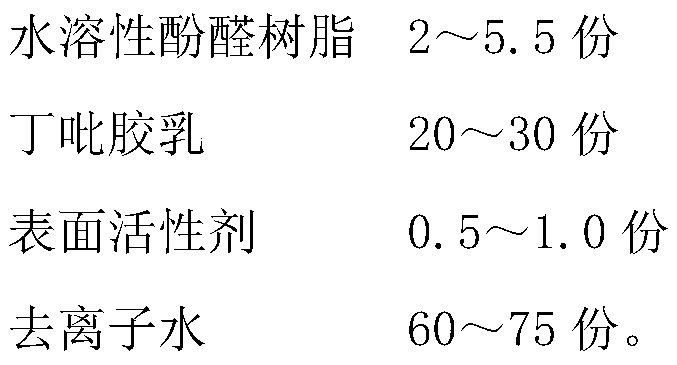

[0034] The dipping liquid includes a first dipping liquid and a second bonding liquid; wherein the first dipping liquid includes: epoxy resin, isocyanate an...

Embodiment 2

[0040] Embodiment 2 discloses a kind of impregnation process for integrally woven canvas, comprising the following preparation steps:

[0041] Step 1, preparation of base cloth

[0042] Polyester industrial yarn is used as the warp thread, nylon industrial yarn is used as the weft thread, and the warp thread and weft thread are woven by the method of integral weaving; among them, 8 warp threads are used, and the weft thread is divided into 4 rows, which are woven by double layers and woven into the base fabric. Standby; wherein, the warp thread density is 180 / 10cm, and the weft thread density is 90 / 10cm; the warp thread is 1000D, and the weft thread is 700D. The twist of polyester industrial yarn is 30 twists / 10cm, and the twist of nylon industrial yarn is 20 twists / 10cm.

[0043] Step 2, preparation of dipping solution

[0044] The dipping liquid includes a first dipping liquid and a second bonding liquid; wherein the first dipping liquid includes: epoxy resin, isocyanate a...

Embodiment 3

[0050] Embodiment 3 discloses a kind of impregnation process for integrally woven canvas, comprising the following preparation steps:

[0051] Step 1, preparation of base cloth

[0052] Polyester industrial yarn is used as the warp thread, nylon industrial yarn is used as the weft thread, and the warp thread and weft thread are woven by the method of integral weaving; among them, 8 warp threads are used, and the weft thread is divided into 4 rows, which are woven by double layers and woven into the base fabric. Standby; wherein, the warp thread density is 200 threads / 10cm, and the weft thread density is 100 threads / 10cm; the warp thread is 1200D, and the weft thread is 700D. The twist of polyester industrial yarn is 50 twists / 10cm, and the twist of nylon industrial yarn is 30 twists / 10cm.

[0053] Step 2, preparation of dipping solution

[0054] The dipping liquid includes a first dipping liquid and a second bonding liquid; wherein the first dipping liquid includes: epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weft breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com