Carbon fiber surface coating treatment method

A technology of surface coating and treatment method, applied in the direction of fiber treatment, carbon fiber, flame retardant fiber, etc., can solve the problems of complex operation, harsh experimental conditions, and high equipment requirements, achieve uniform thickness, improve inert surface, and solve poor wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

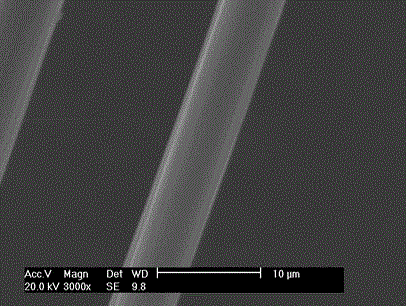

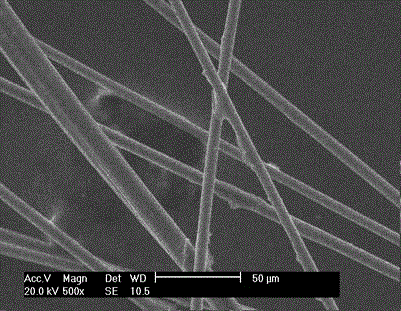

Image

Examples

Embodiment 1

[0043] Step 1. Fiber pretreatment: Burn the carbon fiber at 450°C for 40 minutes, then boil it in a nitric acid solution with a concentration of 15wt%, heat it for 40 minutes, then put it in a 5mol / L acetic acid solution, and place it for 5 min;

[0044] Step 2. Configure the sol solution: mix 1mol / L ethyl orthosilicate, 2mol / L ethanol, 15mol water and 0.2mol / L hydrochloric acid, adjust the pH of the sol solution to 2 with ammonia water, stir evenly, and let stand for 60 minutes;

[0045] Step 3, sol-gel coating treatment: place the pretreated carbon fiber obtained in step 1 in the sol solution obtained in step 2, and oscillate for 30 min with an ultrasonic oscillator, and the temperature of the water bath is 50℃, and finally the surface coated with Dense SiO 2 Coated carbon fiber.

Embodiment 2

[0047] Step 1. Fiber pretreatment: Burn the carbon fiber at 480°C for 30 minutes, then boil it in a 25wt% nitric acid solution, heat it for 50 minutes, then put it in a 6mol / L acetic acid solution, and place it for 8 min;

[0048] Step 2, configure the sol solution: mix 3mol / L ethyl orthosilicate, 3mol / L methanol, 10mol water and 0.5mol / L hydrochloric acid, adjust the pH of the sol solution to 6 with ammonia water, stir evenly, and let stand for 60 minutes;

[0049] Step 3, sol-gel coating treatment: place the pretreated carbon fiber obtained in step 1 in the sol solution obtained in step 2, and oscillate for 60 min with an ultrasonic oscillator, and the temperature of the water bath is 70°C. Dense SiO 2 Coated carbon fiber.

Embodiment 3

[0051] Step 1. Fiber pretreatment: Burn the carbon fiber at 500°C for 50 min, then boil it in a 30wt% nitric acid solution, heat it for 50 min, then put it in an 8mol / L acetic acid solution, and place it for 6 min;

[0052] Step 2, configure the sol solution: mix 2.5mol / L ethyl orthosilicate, 2mol / L methanol, 15mol water and 0.5mol / L hydrochloric acid, adjust the pH of the sol solution to 7 with ammonia water, stir evenly, and let stand for 90 min;

[0053] Step 3. Sol-gel coating treatment: Put the pretreated carbon fiber obtained in step 1 into the sol solution obtained in step 2, and oscillate for 45 minutes with an ultrasonic oscillator, and the temperature of the water bath is 70°C. Dense SiO 2 Coated carbon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com