Slot running device after cutting head of small bar and flying shear

A technology for cutting heads and bars, which is applied in the field of small-sized bar cutting and flying shears, and can solve problems such as no good solutions, and achieve the effects of simple structure, reliable collection, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

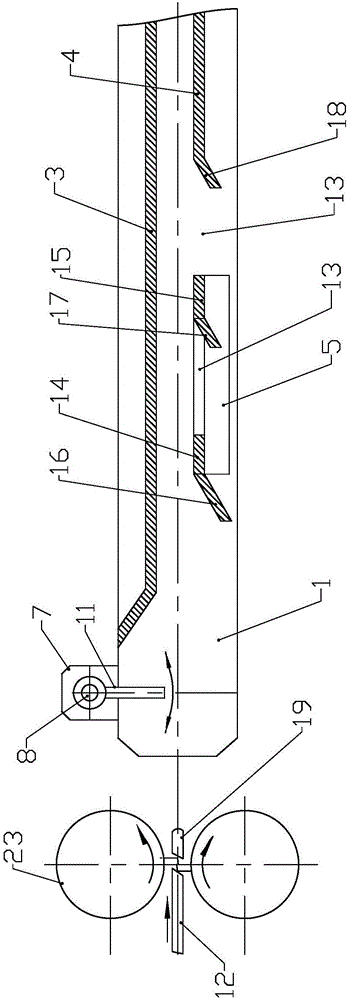

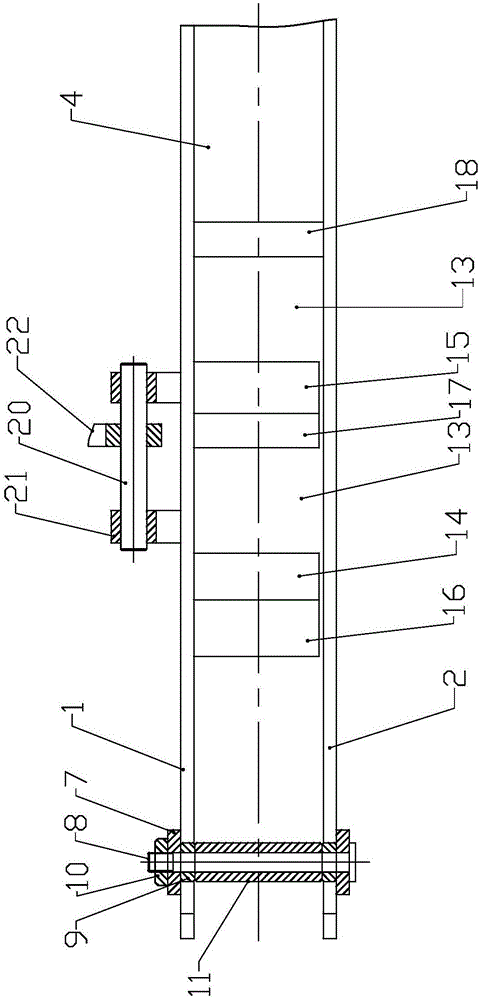

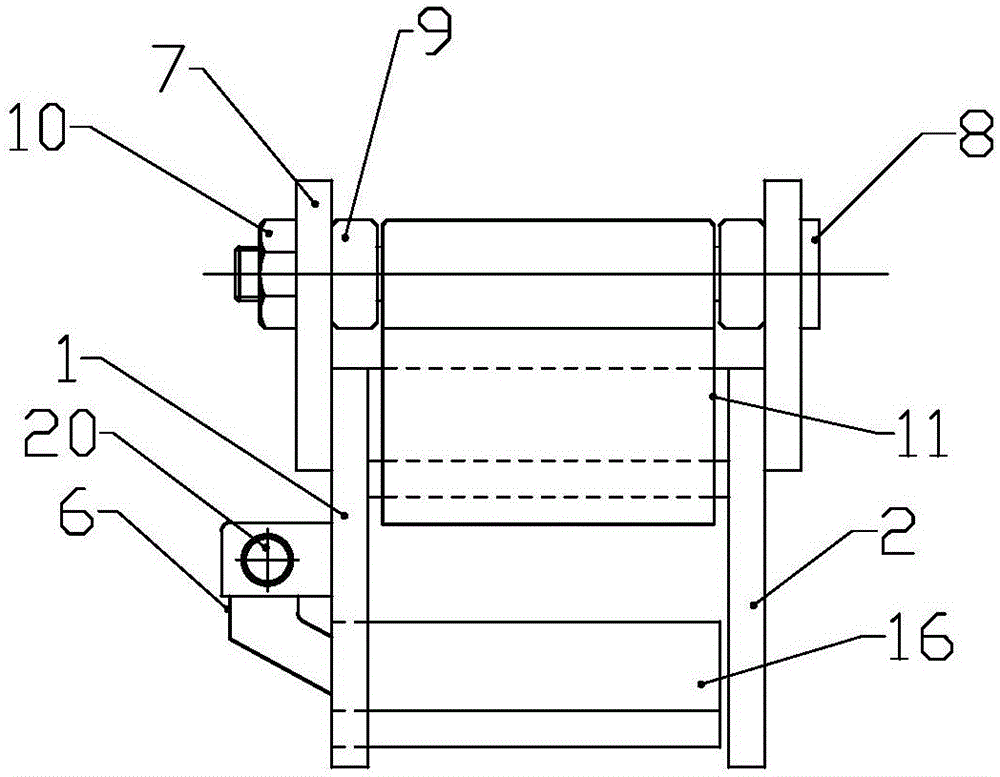

[0017] Refer to the attached figure 1 to attach image 3 The groove-running device after the small-sized bar cutting and flying shear of the present invention is described in detail below.

[0018] The rear trough running device of the small-sized bar cutting head flying shear of the present invention includes a rear trough running mechanism, and the rear trough running mechanism includes a left guard plate 1, a right guard plate 2, an upper guard plate 3, and a fixed bottom plate 4. The movable flap 5 and the movable flap turning drive mechanism 6, the upper guard 3 is arranged on the upper part between the left guard 1 and the right guard 2, the movable flap 5 and the fixed bottom plate 4 are respectively located at the lower part of the upper guard plate 3, the fixed bottom plate 4 is arranged on the rear side of the movable flap 5, and the left end of the movable flap 5 passes through the left guard plate 1 and the movable flap turning drive mechanism 6 Connected, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com