Resin-based high-viscosity heat-resistant grinding wheel material

A high-viscosity, resin-based technology, used in abrasives, manufacturing tools, metalworking equipment, etc., to solve problems such as poor viscosity and heat resistance, and low life of phenolic resin grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

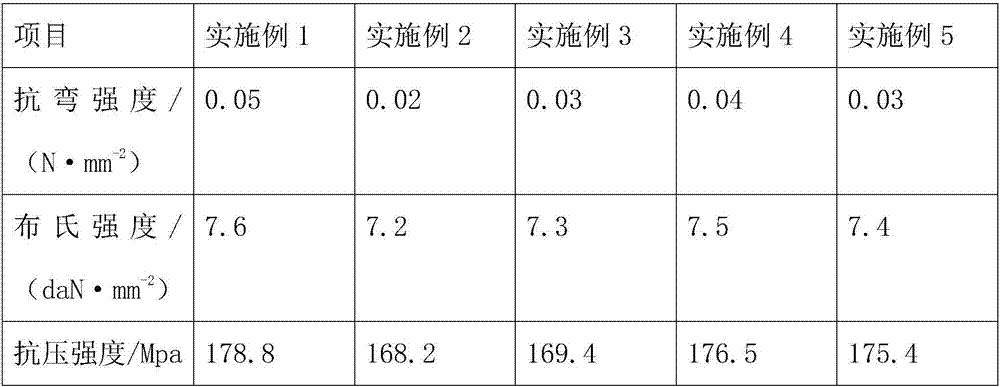

Examples

Embodiment 1

[0015] A resin-based high-viscosity heat-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 45 parts of modified phenolic resin, 10 parts of bisphenol A epoxy resin, 3.5 parts of silicone resin, 6 parts of polyimide resin , 4 parts of bismaleimide, 6 parts of zinc stearate, 3.5 parts of graphite, 2.5 parts of precipitated calcium carbonate, 4.5 parts of titanium dioxide, 3 parts of diamond, 3.5 parts of cerium oxide, 4.5 parts of talcum powder, 6 parts of silicon carbide, 4 parts of silicon dioxide, 3.5 parts of silicon nitride, 4.5 parts of aluminum oxide, 4.5 parts of boron oxide, 3.5 parts of boron nitride, 4 parts of azodicarbonamide, 2.5 parts of imidazole, 2.5 parts of phenyltrimethoxysilane, 4 , 3.5 parts of 4-oxobisbenzenesulfonyl hydrazide, 3 parts of silane coupling agent KH-570, 4.5 parts of wear-resistant additive.

[0016] The modified phenolic resin is prepared according to the following process: mix 20 parts o...

Embodiment 2

[0019] A resin-based high-viscosity heat-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 40 parts of modified phenolic resin, 15 parts of bisphenol A epoxy resin, 2 parts of silicone resin, and 8 parts of polyimide resin , 2 parts of bismaleimide, 9 parts of zinc stearate, 2 parts of graphite, 4 parts of precipitated calcium carbonate, 3 parts of titanium dioxide, 5 parts of diamond, 2 parts of cerium oxide, 6 parts of talcum powder, 4 parts of silicon carbide, 6 parts of silicon dioxide, 2 parts of silicon nitride, 8 parts of aluminum oxide, 3 parts of boron oxide, 5 parts of boron nitride, 2 parts of azodicarbonamide, 4 parts of imidazole, 1 part of phenyltrimethoxysilane, 4 parts , 5 parts of 4-oxobisbenzenesulfonyl hydrazide, 2 parts of silane coupling agent KH-570, 6 parts of wear-resistant additive.

[0020] The modified phenolic resin is prepared according to the following process: mix 15 parts of phenolic resin,...

Embodiment 3

[0023] A resin-based high-viscosity heat-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 50 parts of modified phenolic resin, 5 parts of bisphenol A epoxy resin, 5 parts of silicone resin, 4 parts of polyimide resin , 6 parts of bismaleimide, 3 parts of zinc stearate, 5 parts of graphite, 1 part of precipitated calcium carbonate, 6 parts of titanium dioxide, 1 part of diamond, 5 parts of cerium oxide, 3 parts of talcum powder, 8 parts of silicon carbide, 2 parts of silicon dioxide, 5 parts of silicon nitride, 1 part of aluminum oxide, 6 parts of boron oxide, 2 parts of boron nitride, 6 parts of azodicarbonamide, 1 part of imidazole, 4 parts of phenyltrimethoxysilane, 4 parts , 2 parts of 4-oxobisbenzenesulfonyl hydrazide, 4 parts of silane coupling agent KH-570, and 3 parts of wear-resistant additive.

[0024] The modified phenolic resin is prepared according to the following process: mix 25 parts of phenolic resin, 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com