A heat-resistant and wear-resistant flux-cored welding wire

A flux-cored welding wire, heat-resistant technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of high price, achieve grain refinement, improve high-temperature tempering stability, and excellent heat resistance The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

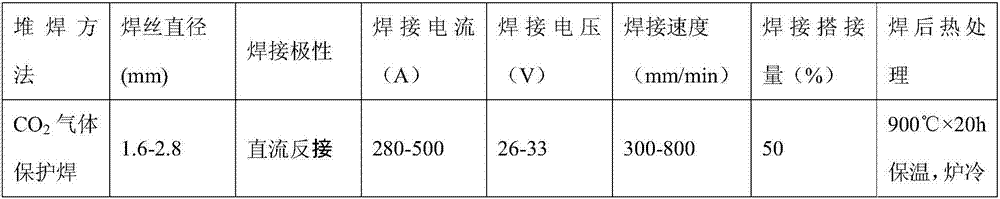

Embodiment 1

[0023] Heat-resistant and wear-resistant flux-cored welding wire, which is composed of low-carbon cold-rolled steel strip wrapped flux core powder.

[0024] First select a low-carbon cold-rolled steel strip with a width of 14mm and a thickness of 0.3mm, and press it into a U-shape by a forming machine; then fill the U-shaped groove with flux-core powder, which accounts for 36% of the mass of the flux-cored wire; Then the opening of the U-shaped groove is closed to form an O shape, so that the core powder is wrapped in it, and the wire drawing machine is drawn and reduced in diameter according to the conventional method to obtain a welding wire of Ф1.6mm, which is the heat-resistant and wear-resistant chemical of the present invention. cored wire.

[0025] The weight percent composition of the drug core powder is as follows: 0.2% of nanoscale graphene, 45% of metallic chromium, 8% of electrode graphite, 2% of marble, 1.5% of chromium carbide, 1.6% of electrolytic manganese meta...

Embodiment 2

[0027] Heat-resistant and wear-resistant flux-cored welding wire, which is composed of low-carbon cold-rolled steel strip wrapped flux core powder.

[0028] First select a low-carbon cold-rolled steel strip with a width of 14mm and a thickness of 0.3mm, and press it into a U-shape through a forming machine; then fill the U-shaped groove with flux-core powder, which accounts for 46% of the mass of the flux-cored wire; Then close the opening of the U-shaped groove to form an O shape, so that the core powder is wrapped in it, and then drawn and reduced in diameter by a wire drawing machine to obtain a welding wire of Ф2.8mm, which is the heat-resistant and wear-resistant flux-cored welding wire of the present invention.

[0029] The weight percent composition of the drug core powder is as follows: 1.0% of nano-graphene, 42% of metallic chromium, 7% of electrode graphite, 4% of marble, 1% of chromium carbide, 2% of electrolytic manganese, 6% of ferrosilicon, and 6% of molybdenum ,...

Embodiment 3

[0031] Heat-resistant and wear-resistant flux-cored welding wire, which is composed of low-carbon cold-rolled steel strip wrapped flux core powder.

[0032] First select a low-carbon cold-rolled steel strip with a width of 14mm and a thickness of 0.25mm, and press it into a U-shape by a forming machine; then fill the U-shaped groove with flux-core powder, which accounts for 40% of the mass of the flux-cored wire; Then close the opening of the U-shaped groove to form an O shape, so that the core powder is wrapped in it, and then drawn and reduced in diameter by a wire drawing machine to obtain a welding wire of Ф2.0 mm, which is the heat-resistant and wear-resistant flux-cored welding wire of the present invention.

[0033] The weight percent composition of the drug core powder is as follows: 0.8% of nanoscale graphene, 40% of metal chromium powder, 5% of electrode graphite, 3% of marble, 2% of chromium carbide, 3% of electrolytic manganese powder, and 4% of ferrosilicon powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com