A wear-resistant surfacing flux-cored welding wire with uniform hardness of deposited metal

A technology of uniform hardness and deposited metal, applied in metal processing equipment, welding equipment, welding medium, etc., can solve the problem that the melting rate of cored Chinese medicine powder particles is difficult to guarantee, and it is impossible to increase the wear resistance of surfacing welding and the hardness of deposited metal. Uneven distribution and other problems, to achieve the effect of uniform hardness distribution, grain refinement and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

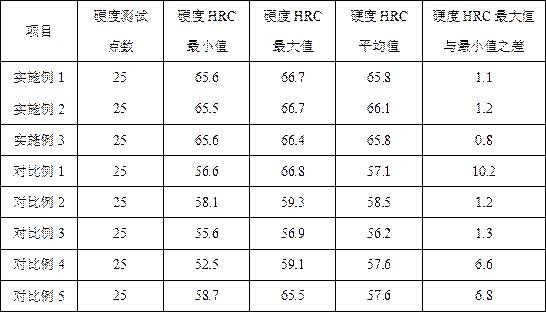

Embodiment 1

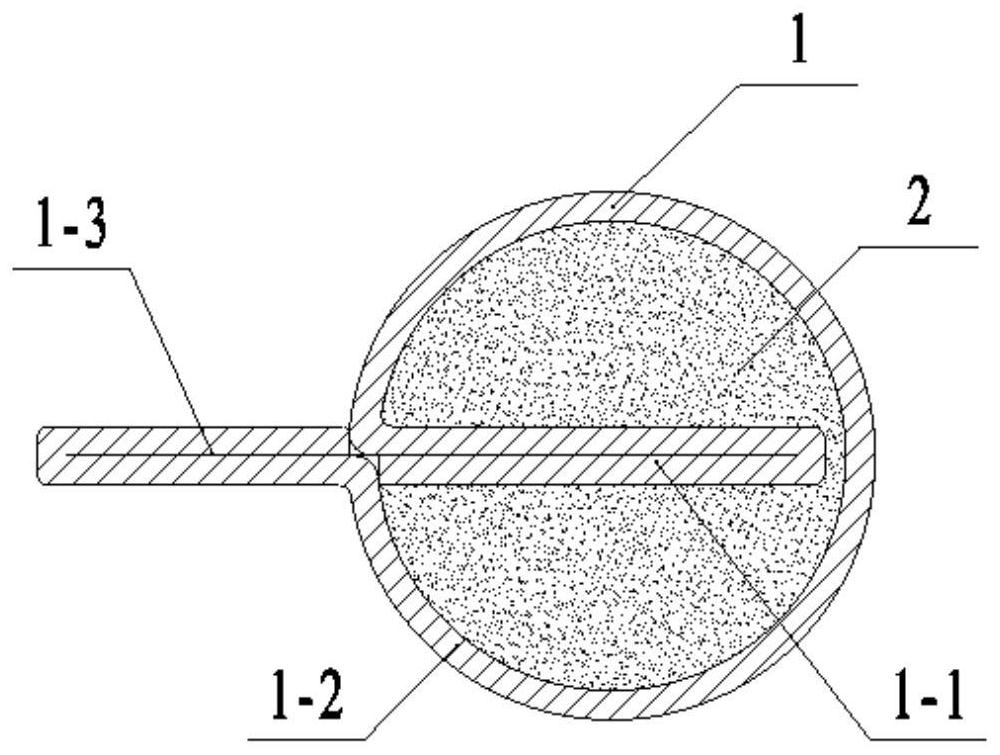

[0025] Such as figure 1 As shown, a wear-resistant surfacing flux-cored welding wire with uniform hardness of the deposited metal, on the cross section perpendicular to the length of the welding wire, the outer skin 1 includes an inner extension part 1-1, a flux core wrapping part 1-2 and an outer extension part 1- 3. The outer skin 1 first extends from the head to the tail in the horizontal direction for a while, then folds back 180° back to the head to form the inner extension 1-1, and then wraps the drug core wrapping part 1-2 and the inner extension 1-1 The head is closed, and then reversely extended to the outside of the drug core wrapping part 1-2 for a period of time, and then folded 180° back to the head of the inner extension part 1-1 and closed with the drug core wrapping part 1-2 to form the outer extension part 1-3 .

[0026] The drug core wrapping part 1-2 is circular, and the drug core 2 is filled in the drug core wrapping part 1-2.

[0027] The chemical compos...

Embodiment 2

[0029] Prepare the structural shape of the flux-cored wire according to Example 1.

[0030] The chemical composition and dosage of drug core 2 are calculated by mass percentage: 9% of nano-lanthanum hexaboride, 16% of FeCr30Si40-A silicon chromium alloy, 5% of hollow cage carbon microspheres, 11% of manganese fluoride, and 3% of potassium carbonate , and the balance is FHT100·25 reduced iron powder.

Embodiment 3

[0032] Prepare the structural shape of the flux-cored wire according to Example 1.

[0033] The chemical composition and dosage of drug core 2 are calculated by mass percentage: 7.5% of nano-lanthanum hexaboride, 13% of FeCr30Si40-A silicon chromium alloy, 4% of hollow cage carbon microspheres, 9.5% of manganese fluoride, and 2.5% of potassium carbonate , and the balance is FHT100·25 reduced iron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com