Light and high-strength rubber conveyor belt and preparation method thereof

A conveyor belt and high-strength technology, which is applied in the field of lightweight high-strength rubber conveyor belt and its preparation, can solve the problems of ultra-high molecular weight polyethylene strength damage, unsuitable for industrial production, and production of toxic substances, so as to achieve low cost, avoid melting damage, Effect of improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

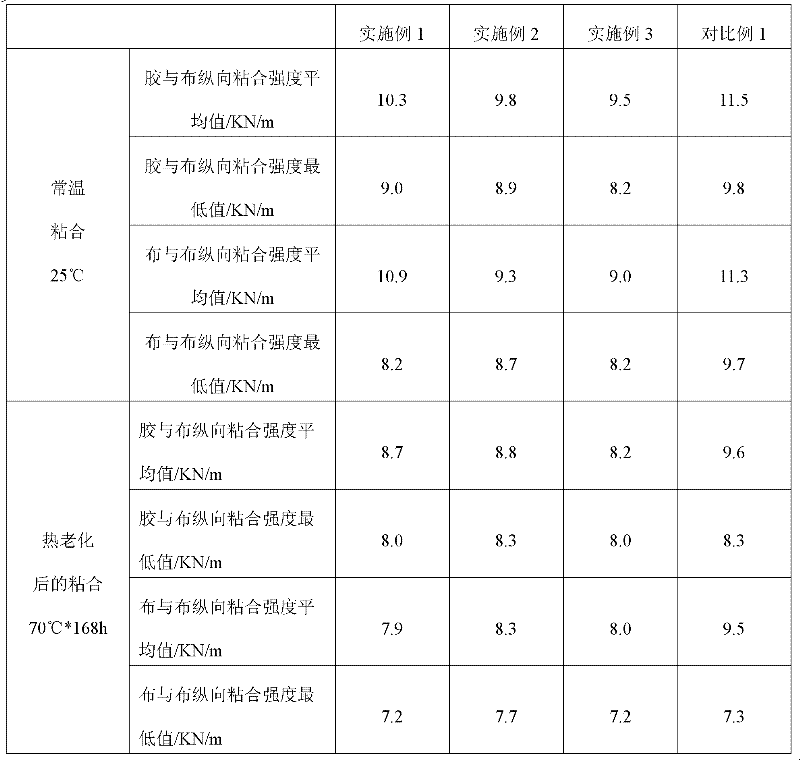

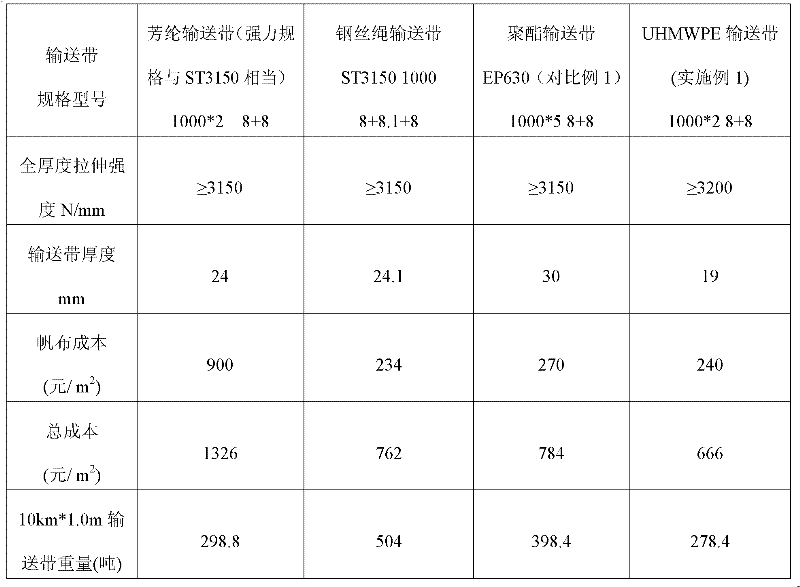

Embodiment 1

[0066] (1) Dipping treatment of skeleton layer:

[0067] Preparation of the dipping solution: add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 40° C. for 4 hours to obtain a phenolic resin solution.

[0068] Stir chlorosulfonated polyethylene latex and silane coupling agent KH560[3-(2,3-epoxypropoxy)propyltrimethoxysilane] evenly in another stirring tank to obtain latex containing silane coupling agent .

[0069] Slowly add the phenolic resin solution into the latex containing the silane coupling agent and stir evenly. Stand at room temperature for 16 hours to obtain a dipping solution. The mass percentage of each component added is: water 54.19%, resorcinol 1.86%, formaldehyde 1%, sodium hydroxide 0.05%, chlorosulfonated polyethylene latex 41.20%, silane coupling agent KH560 1.7% .

[0070] Dipping treatment of the canvas: UHMWPE canvas treated with plasma (provided by Ningbo Dacheng New Material Co., Ltd., model DC...

Embodiment 2

[0080] (1) Dipping treatment of skeleton layer:

[0081] Preparation of the dipping solution: add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 30° C. for 5 hours to obtain a phenolic resin solution.

[0082] In another stirring tank, chlorosulfonated polyethylene latex, silane coupling agent wetlink-78 (r-glycidyl ether glycidyl methyldiethoxysilane produced by U.S. General Silicone Company) are stirred evenly to obtain Latex of silane coupling agent.

[0083] Slowly add the phenolic resin solution into the latex containing the silane coupling agent and stir evenly. Stand at room temperature for 20 hours to obtain a dipping solution. The mass percentage of each component added is: water 45.00%, resorcinol 2.00%, formaldehyde 1.03%, sodium hydroxide 0.06%, neoprene latex 43.00%, silane coupling agent wetlink-788.91%.

[0084] Dipping treatment of the canvas: plasma-treated ultra-high molecular weight polyethylene canva...

Embodiment 3

[0094] (1) Dipping treatment of skeleton layer:

[0095] Preparation of the dipping solution: add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 50° C. for 3 hours to obtain a phenolic resin solution.

[0096] In another stirring tank, the chlorosulfonated polyethylene latex and the silane coupling agent LG9800 (isocyanate silane coupling agent) were stirred evenly to obtain the latex containing the silane coupling agent.

[0097] Slowly add the phenolic resin solution into the latex containing the silane coupling agent and stir evenly. Stand at room temperature for 24 hours to obtain a dipping solution. The mass percent content of each component added is: water 56.00%, resorcinol 1.50%, formaldehyde 0.68%, sodium hydroxide 0.04%, hydrogenated nitrile latex 36.57%, silane coupling agent LG9800 5.21%.

[0098] Dipping treatment of canvas: plasma-treated ultra-high molecular weight polyethylene canvas (provided by Ningbo D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com