Titanium dioxide film and preparation method and application thereof

A technology of titanium dioxide and thin film, which is applied in the field of titanium dioxide thin film and its preparation, can solve the problems of complex preparation process and dissolution of toxic metal ions, and achieve low deposition temperature, good step coverage and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the invention has the advantages of simple operation, low deposition temperature, high film bonding strength, precise control of film thickness, uniform coating on three-dimensional samples, good repeatability, and the like.

[0033] The method for preparing a titanium dioxide thin film by atomic layer deposition technology provided by the present invention is exemplarily described below.

[0034] After the substrate is placed in the reaction chamber of the atomic layer deposition equipment, the reaction chamber is evacuated to 5-10 mbr, and the substrate is heated to 180-250° C.

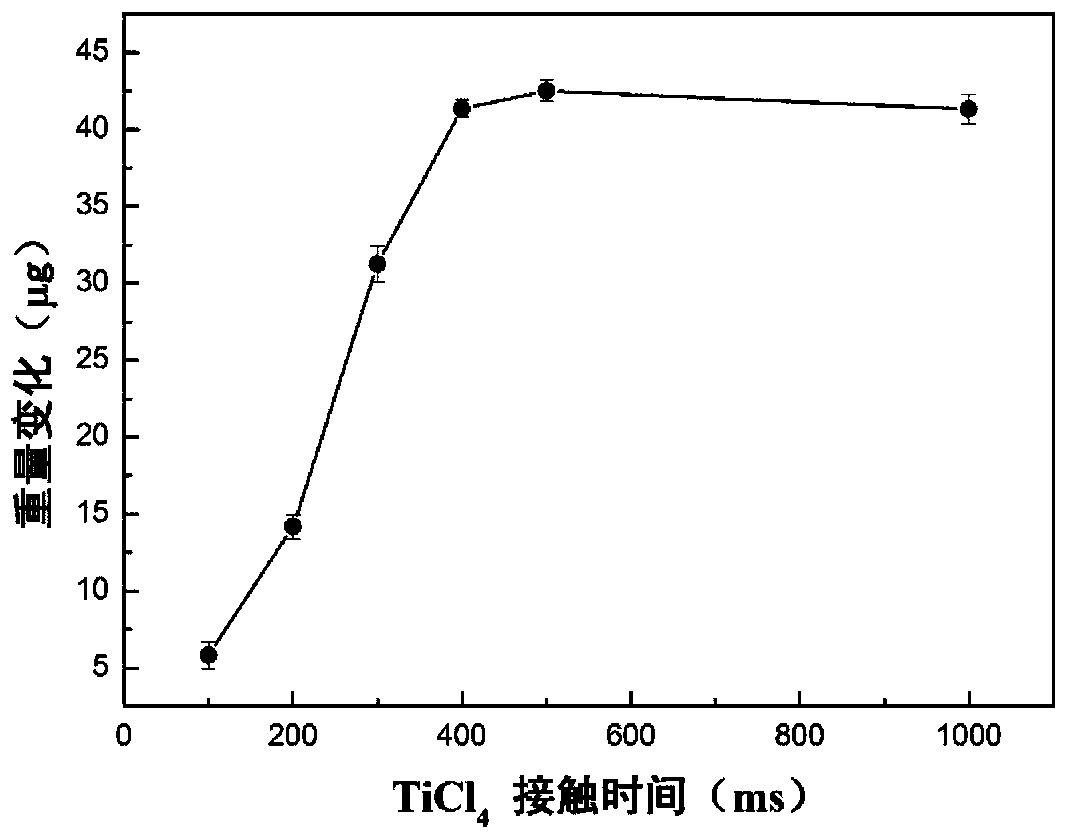

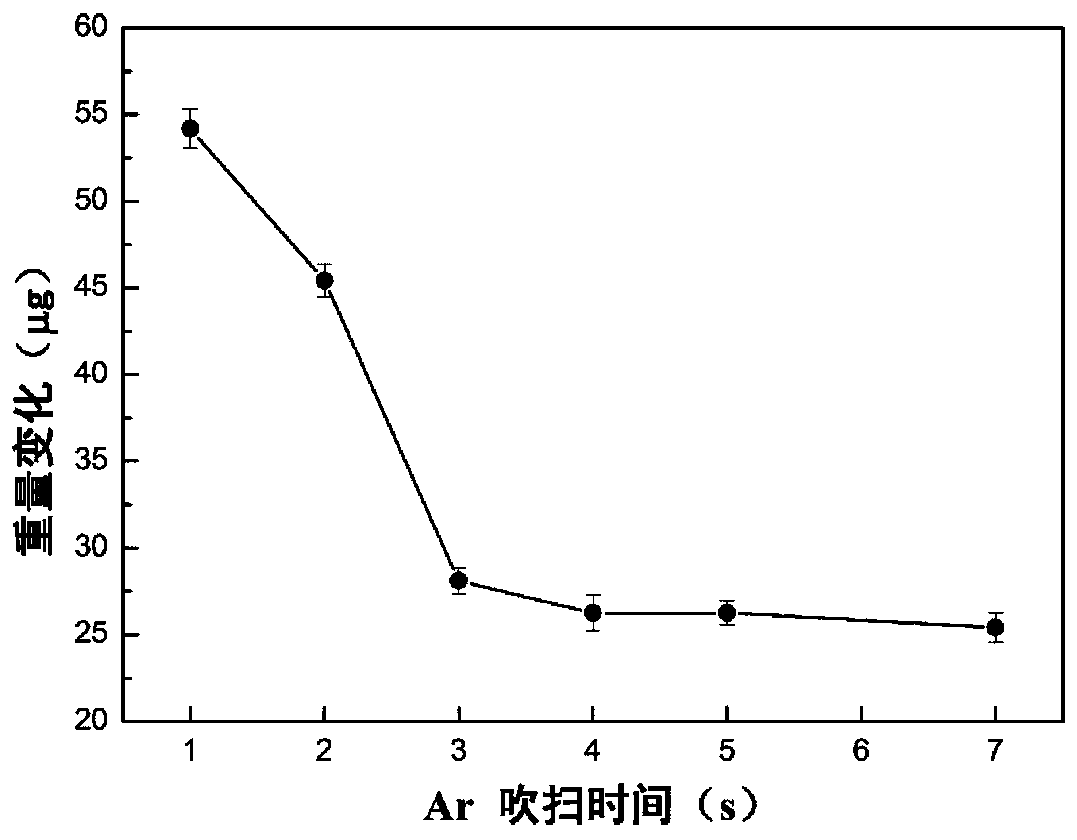

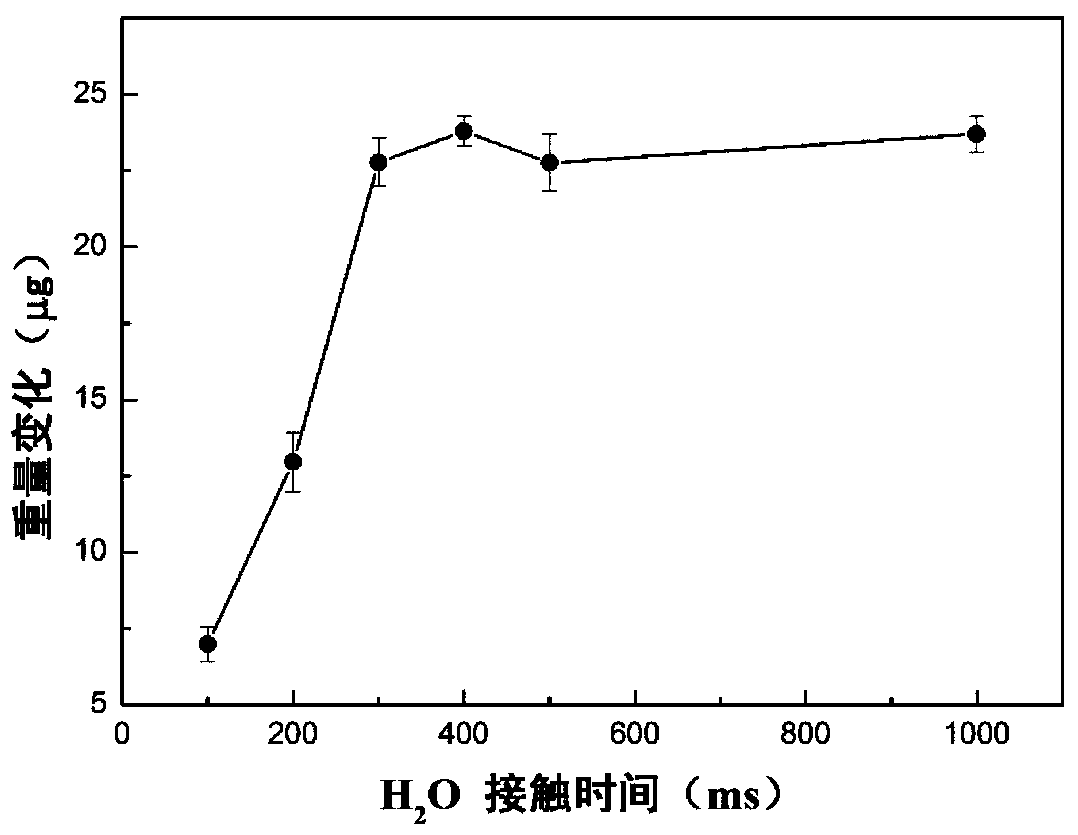

[0035] The titanium-containing precursor is passed into the reaction chamber for 100-1000 milliseconds, so that the titanium-containing precursor is adsorbed on the surface of the substrate. Then purging with an inert gas for 1 to 7 seconds to leave a single layer of titanium-containing precursor molecules on the surface of the substrate. Wherein the titanium-containi...

Embodiment 1

[0042] A: Anatase thin film prepared by atomic layer deposition technology

[0043] The (100) single crystal silicon substrate was cleaned successively with alcohol and deionized water in an ultrasonic cleaner, dried, and loaded into the reaction chamber of BENEQTFS-500 atomic layer deposition equipment. Vacuum to 6-8mbar, heat the substrate to 200°C for TiO 2 deposition. Introduce TiCl into the reaction chamber 4 500 milliseconds, followed by a 4-second purge with an inert gas flow rate of 200 sccm. Then water vapor was introduced into the reaction chamber for 500 milliseconds, and finally an inert gas with a flow rate of 200 sccm was purged for 4 seconds to complete a deposition cycle. Cycle 1500 times. After the deposition is completed, the deposition chamber is inflated to restore an atmospheric pressure, and the sample is taken out, cooled, and set aside.

[0044] Depend on Figures 1a-1d It can be seen that the deposition rate reaches a stable value after the precu...

Embodiment 2

[0063] Preparation of Anatase Thin Films by Atomic Layer Deposition

[0064] A Φ10mm×2mm thick titanium alloy was used as the base material, which was cleaned with alcohol and deionized water in an ultrasonic cleaner, dried, and loaded into the reaction chamber of BENEQ TFS-500 atomic layer deposition equipment. Vacuum to 6-8mbar, heat the substrate to 200°C for TiO 2 deposition. Introduce TiCl into the reaction chamber 4 500 milliseconds, followed by a 4-second purge with an inert gas flow rate of 200 sccm. Then water vapor was introduced into the reaction chamber for 500 milliseconds, and finally an inert gas with a flow rate of 200 sccm was purged for 4 seconds to complete a deposition cycle. Cycle 800 times. After the deposition, the deposition chamber was inflated to return to an atmospheric pressure to obtain a titanium alloy sample covered with an anatase phase film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com