Soundproof floor mat

A floor mat and sound insulation material technology, applied in the field of sound insulation floor mats, can solve problems such as single, no sound insulation, and difficulty in achieving sufficient sound insulation, and achieve the effects of improving dimensional stability, improving quality of life, and good initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

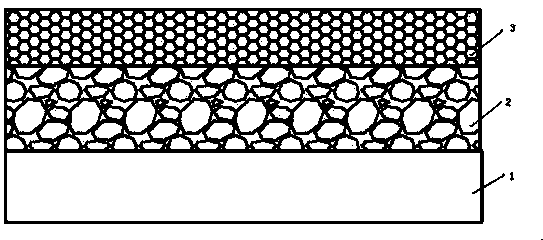

[0040] like figure 1 As shown, the soundproof floor mat includes the first moisture-proof film layer 1 arranged on the bottom layer, the fully open-cell foam material layer 2 arranged on the middle layer and on the first moisture-proof film layer 1, and the upper layer and located on the first moisture-proof film layer 1. The closed-cell foam material layer 3 on the fully open-cell foam material or the cork layer 2; wherein the first moisture-proof film layer 1 is PE film or aluminum film or metal moisture-proof paper layer; the closed-cell foam layer arranged on the upper layer The material layer 3 is a polyethylene modified sound-insulating material layer. The thickness of the fully open-cell foaming material layer or the cork layer is 0.1 cm; the thickness of the closed-cell foaming material layer is 0.1 cm.

[0041] The preparation method of polyethylene modified sound insulation material comprises the following steps in sequence:

[0042] (1) Raw material preparation: 3...

Embodiment 2

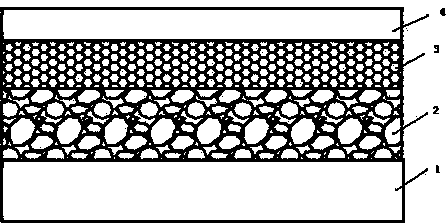

[0061] like figure 2 As shown, the sound-insulating floor mat includes a first moisture-proof film layer 1 disposed on the bottom layer, a fully open-cell foam material layer 2 disposed on the middle layer and on the first moisture-proof film layer 1, and a fully open-cell foam material layer 2 on the first moisture-proof film layer 1. The closed-cell foam material layer 3 on the layer 2 and the second moisture-proof film layer 4 on the closed-cell foam material layer 3; wherein the first moisture-proof film layer 1 and the second moisture-proof film layer 4 are PE film or aluminum film or The metal moisture-proof paper layer; the closed-cell foam material layer 3 is a polyethylene modified sound-insulating material layer. The thickness of the fully open-cell foaming material layer or the cork layer is 2cm; the thickness of the closed-cell foaming material layer is 2cm.

[0062] The preparation method of polyethylene modified sound insulation material comprises the following...

Embodiment 3

[0071] like figure 2 As shown, the soundproof floor mat includes a first moisture-proof film layer 1 arranged on the bottom layer, a sawdust pressed cork layer 2 arranged on the middle layer and on the first moisture-proof film layer 1, and a cork EVA foam material layer 2 The closed-cell foam material layer 3 and the second moisture-proof film layer 4 on the closed-cell foam material layer 3; wherein the first moisture-proof film layer 1 and the second moisture-proof film layer 4 are PE film or aluminum film or metal moisture-proof paper Layer; the closed-cell foam material layer 3 is a polyethylene modified sound-insulating material layer. The thickness of the fully open-cell foaming material layer or the cork layer is 0.5 cm; the thickness of the closed-cell foaming material layer is 0.5 cm.

[0072] The preparation method of polyethylene modified sound insulation material comprises the following steps in sequence:

[0073] (1) Raw material preparation: 45 parts of polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com