Pavement crack repairing material and preparation method

A technology for repairing cracks in materials and pavements. It is applied in the direction of asphalt material adhesives, roads, roads, etc. It can solve the problems that cannot meet the requirements of road maintenance, and achieve the goal of improving damage resistance, increasing specific surface area, and good crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, each component is weighed according to the formula quantity, petroleum asphalt 49%; Modifier 10%; Special scrap powder 6%; Plasticizer 3%; Softening oil 10%; Waste rubber powder 15%; Tackifier 7%;

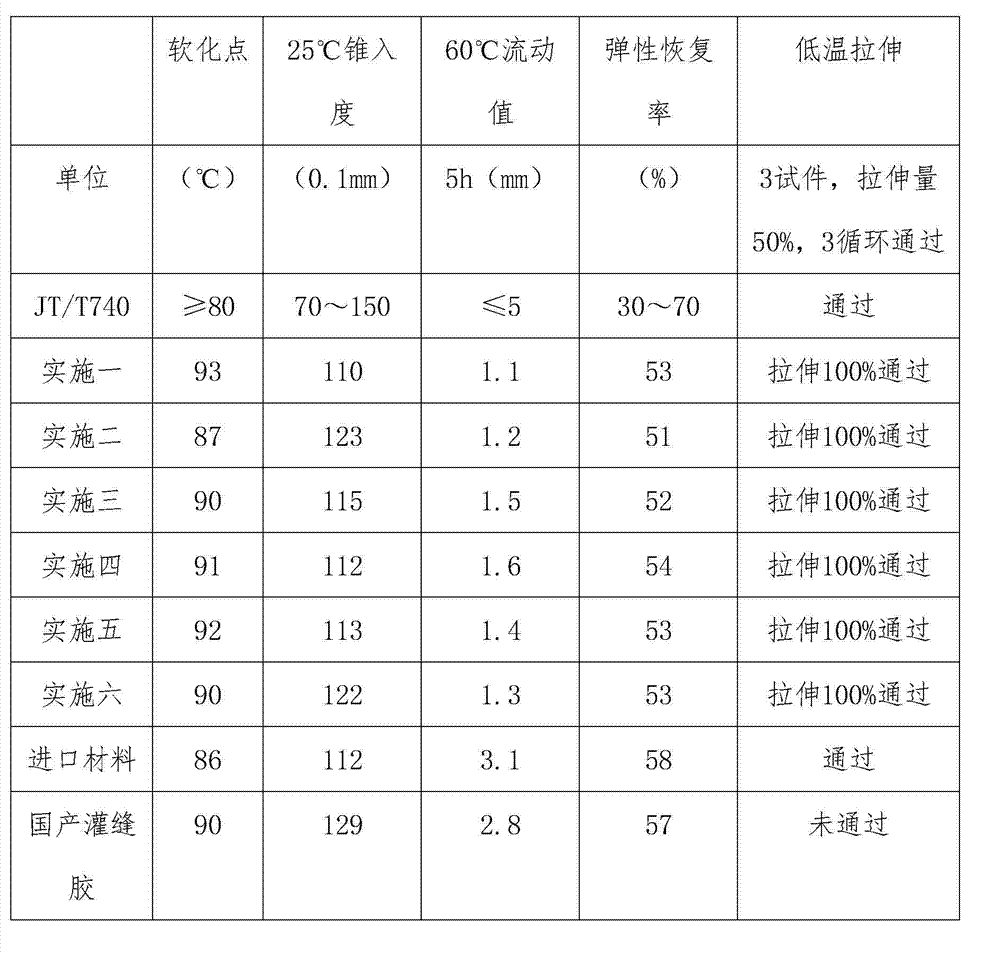

[0028] Heat petroleum asphalt to 170°C, add plasticizer and special scrap powder, heat up to 205°C, stir at 90r / min for 2h to dissolve, cool down to 190°C, add softening oil and modifier to grind for 30min, then add viscosity increaser After mixing the agent and waste rubber powder evenly. The measured material properties are listed in Table 1.

Embodiment 2

[0029] Embodiment two, each component is weighed by formula quantity, petroleum asphalt 44%; Modifier 8%; Special scrap powder 9%; Plasticizer 5%; Softening oil 12%; Waste rubber powder 15%; 7%;

[0030] Heat petroleum asphalt to 170°C, add plasticizer and special scrap powder, heat up to 210°C, stir at 90r / min for 2h to dissolve, cool down to 190°C, add softening oil and modifier to grind for 30min, then add waste rubber The powder and nano-oxide are mixed evenly. The measured material properties are listed in Table 1.

Embodiment 3

[0031] Embodiment 3, each component is weighed according to the formula quantity, petroleum asphalt 35%; Modifier 12%; Special scrap powder 10%; Plasticizer 5%; Softening oil 15%; Waste rubber powder 20%; Tackifier 3%;

[0032] Heat petroleum asphalt to 165°C, add plasticizer and special scrap powder, heat up to 200°C, stir at 80r / min for 2h to dissolve, cool down to 185°C, add softening oil and modifier to grind for 30min, then add waste rubber Mix the powder and tackifier evenly. The measured material properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com