High temperature resistant vacuum bag sealing adhesive tape

A technology for sealing tapes and vacuum bags, applied in the directions of adhesives, polymer adhesive additives, adhesive types, etc., which can solve the problems of air leakage, separation of release paper and glue, poor high temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

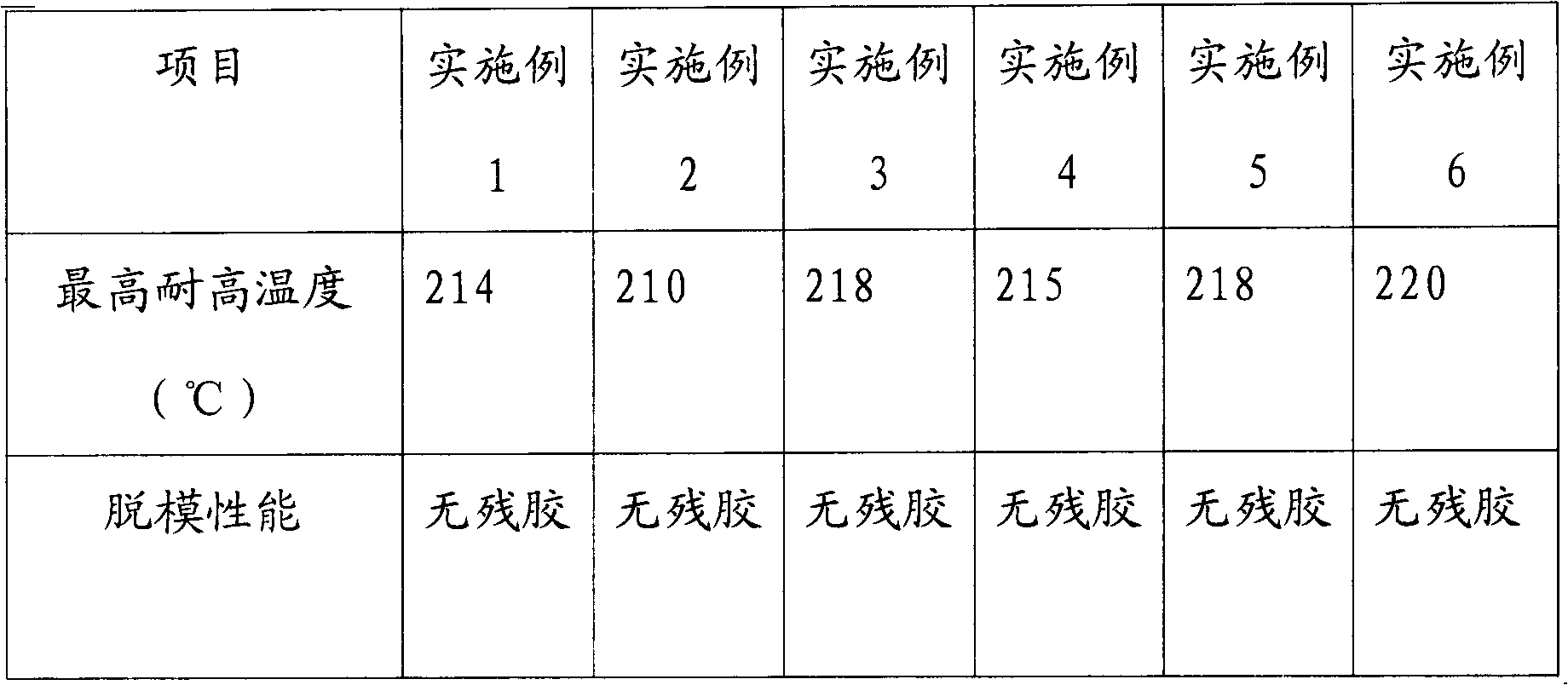

Examples

Embodiment 1

[0017] Main matrix: 5 parts of butyl rubber, 5 parts of neoprene rubber, 15 parts of polyisobutylene, 25 parts of nano-calcium carbonate;

[0018] Recessive high-temperature vulcanizing agent: 1.3 parts, choose phenolic resin;

[0019] Other additives: 2 parts of glass fiber, 25 parts of superfine talcum powder, 1.3 parts of zinc oxide, 0.8 part of stearic acid, 1.0 part of tackifying resin, 1.0 part of titanium dioxide, 0.8 part of organic yellow, and 1.5 parts of plasticizer.

Embodiment 2

[0021] Main matrix: 8 parts of butyl rubber, 8 parts of neoprene rubber, 20 parts of polyisobutylene, 30 parts of nano calcium carbonate;

[0022] Recessive high-temperature vulcanizing agent: 2.0 parts, select phenolic resin;

[0023] Other additives: 5 parts of glass fiber, 30 parts of superfine talc, 1.8 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of tackifying resin, 1.5 parts of titanium dioxide, 1.2 parts of organic yellow, and 2.5 parts of plasticizer.

Embodiment 3

[0025] Main matrix: 6 parts of butyl rubber, 6 parts of neoprene rubber, 17 parts of polyisobutylene, 28 parts of nano calcium carbonate;

[0026] Recessive high-temperature vulcanizing agent: 1.7 parts, choose phenolic resin;

[0027] Other additives: 3.5 parts of glass fiber, 27 parts of superfine talc, 1.6 parts of zinc oxide, 1.1 parts of stearic acid, 1.3 parts of tackifying resin, 1.2 parts of titanium dioxide, 1.0 part of organic yellow, and 2.0 parts of plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com