High elasto-plasticity waterproof caulking sealant used in outdoor and preparation method thereof

A caulking sealing and elastic technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of water resistance, weather resistance, low temperature resistance, poor flexibility and sealing performance, can not meet the requirements of the industry, No pollution requirements and high problems, to achieve the effect of good flexibility, good water resistance, and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

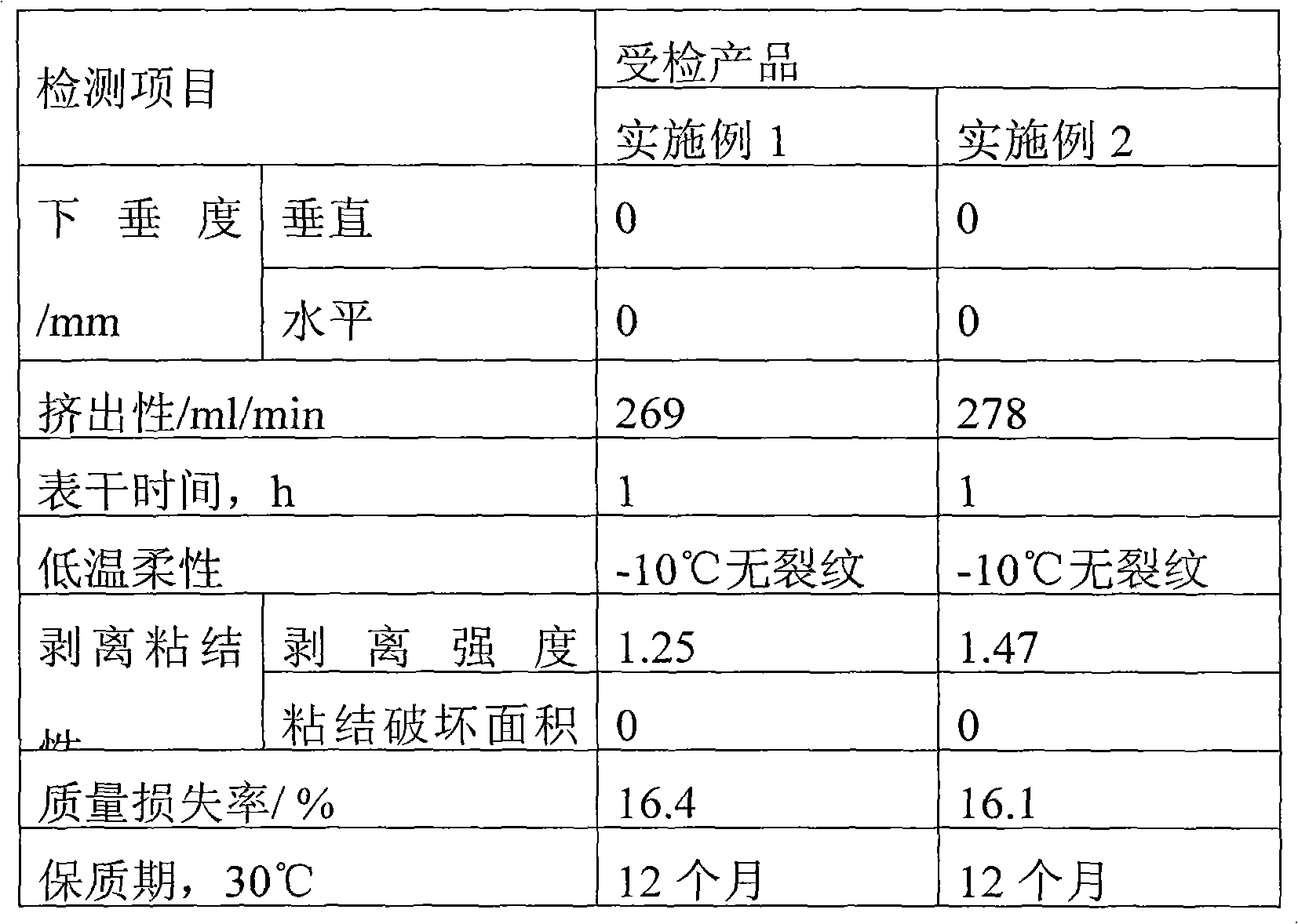

Examples

preparation example Construction

[0030] A preparation method for outdoor high plastic elastic waterproof caulking sealant, comprising the following steps:

[0031] 1) Use a two-roller rubber mixer to refine the base rubber into a sheet, and then cut it into pieces;

[0032] 2) Put the organic solvent, tackifier, softener, anti-aging agent, and the rubber block obtained in step 1) into the reaction kettle, stir and dissolve into glue;

[0033] 3) Put the filler and thickener into the kettle, stir, vacuumize, and discharge to obtain the finished product.

Embodiment 1

[0036] The following table 1 is the raw materials contained in the high plastic elastic waterproof caulking sealant:

[0037] Table 1: Raw materials contained in high plastic elastic waterproof caulk sealant

[0038] raw material

Embodiment 2

[0041] The following table 2 shows the raw materials contained in the high plastic elastic waterproof caulking sealant:

[0042] Table 2: Raw materials contained in high plastic elastic waterproof caulk sealant

[0043] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com