Hot-melt adhesive for bonding layer of artificial leather and preparation method as well as application thereof

A technology of hot-melt adhesive and artificial leather, which is applied in the field of roller coating and knife coating, and can solve the problem of product peel strength, hot-melt adhesive high temperature resistance, chemical resistance, acid resistance, alkali resistance, flexibility and The hardness is difficult to meet the requirements, difficult to use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

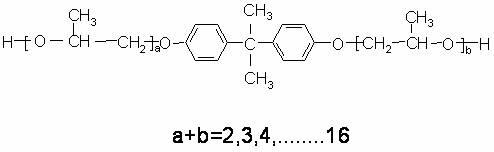

Image

Examples

Embodiment 1

[0082] A kind of water-based polyurethane hot-melt adhesive for artificial leather, its preparation method, comprises the steps: with 100 kilograms of toluene diisocyanate (TDI), molecular weight is 383 kilograms of polybutylene adipate glycols of 2000, drop into reaction React in the kettle at 90°C for 1 hour, add 21 kg of diethylene glycol, 17 kg of dimethylol propionic acid and 0.5 kg of dibutyltin dilaurate and react at 50°C for 5 hours, and use acetone to adjust the viscosity of the system during the reaction After the reaction, cool down to 35°C and add 13 kg of triethylamine and 4,806 kg of water to emulsify to obtain a white emulsion. Distill the emulsion under reduced pressure at 60°C and -0.05MPa to remove acetone, and obtain a solid content of 10%. The left and right artificial leather bonding layers use hot melt adhesive water-based polyurethane emulsion.

Embodiment 2

[0084] A kind of water-based polyurethane hot-melt adhesive for artificial leather, its preparation method, comprises the steps: with 100 kilograms of toluene diisocyanate (TDI), molecular weight is 115 kilograms of polybutylene adipate diols of 2000, epoxy Resin (E51) 27 kg, aromatic polyhydroxyl special polyether (hydroxyl value 110) 55 kg, put into the reaction kettle and react at 60°C for 3 hours, add diethylene glycol 30 kg, dimethylol propionic acid 15 kg Kg and 1.4 kg of dibutyltin dilaurate were reacted at 65°C for 2 hours. During the reaction, 30 kg of acetone and 30 kg of ethyl acetate were used to adjust the viscosity of the system. After the reaction, the temperature was lowered to 50°C and 11 kg of triethylamine and 400 kg of water were added. Emulsify to obtain a white emulsion, distill the emulsion under reduced pressure at 20°C and -0.1MPa to remove acetone and ethyl acetate, and then make a hot-melt adhesive water-based polyurethane for artificial leather adhes...

Embodiment 3

[0086] A kind of water-based polyurethane hot-melt adhesive for artificial leather, its preparation method, comprises the steps: with 100 kilograms of toluene diisocyanate (TDI), molecular weight is 287 kilograms of polybutylene adipate diols of 3000, epoxy Resin (E51) 2.3 kg, aromatic polyhydroxyl special polyether (hydroxyl value 110) 2 kg, put into the reaction kettle and react at 85°C for 1.5 hours, add 30 kg of diethylene glycol, 2.8 kg of trimethylolpropane , 15 kg of dimethylol propionic acid and 0.5 kg of stannous octoate were reacted at 60°C for 4 hours. During the reaction, 100 kg of methyl acetate was used to adjust the viscosity of the system. After the reaction, the temperature was lowered to 35°C and 11 kg of triethylamine was added. 1050 kg of emulsified to obtain a white emulsion, the emulsion was distilled under reduced pressure at 45°C and -0.06MPa to remove methyl acetate, and then a water-based polyurethane hot-melt adhesive for artificial leather adhesive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com