Chloroprene rubber latex adhesive, preparation and uses thereof

A neoprene latex and adhesive technology, which is applied in the direction of neoprene adhesives, adhesives, adhesive types, etc., can solve problems such as poor performance, low performance of latex-type neoprene adhesives, and high prices of imported products. To achieve the effects of sufficient sources, widening the range of bondable substrates, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

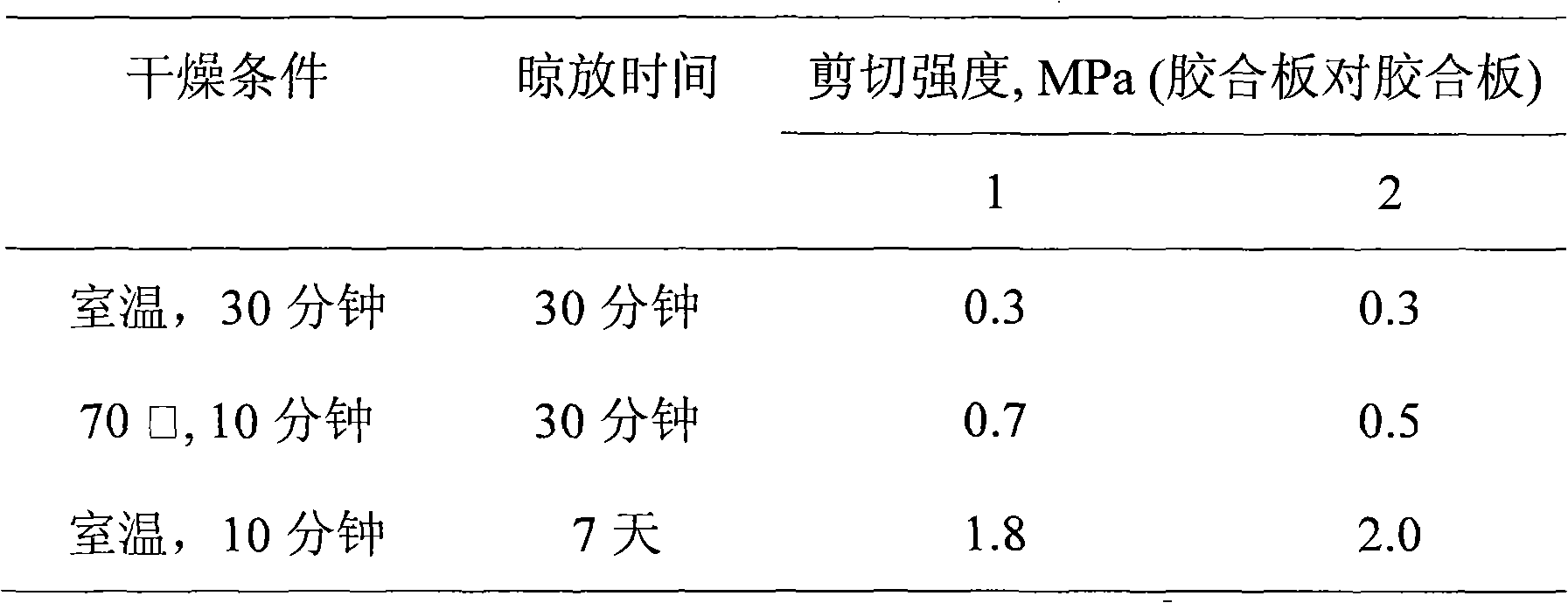

[0050] The neoprene latex adhesive prepared in this example is used for the bonding of mattresses, seat (sleeping) chairs, and sofa sponges, and is bonded by a wet process.

[0051] The chloroprene latex type adhesive of the present embodiment is made up of each component of following mass percentage:

[0052] Neoprene latex (Dispercoll C84 of Bayer company) 30%, styrene-acrylic emulsion 55%, commercially available rosin resin emulsion 14%, sodium lauryl sulphate 0.2%, mass percent concentration is 0.1% of antiaging agent 264 aqueous solution 0.1% of 50% 0.2% of zinc oxide aqueous solution with a concentration of 50% by mass, 0.3% of glycine with a concentration of 5% by mass, and 0.2% of thickener hydroxymethyl cellulose. The mass percentage is the percentage of the total mass of the adhesive weighed.

[0053] Wherein the preparation method of styrene-acrylic emulsion, its detailed steps are as follows: (1) take each monomer of following mass percent: butyl acrylate 40%, sty...

Embodiment 2

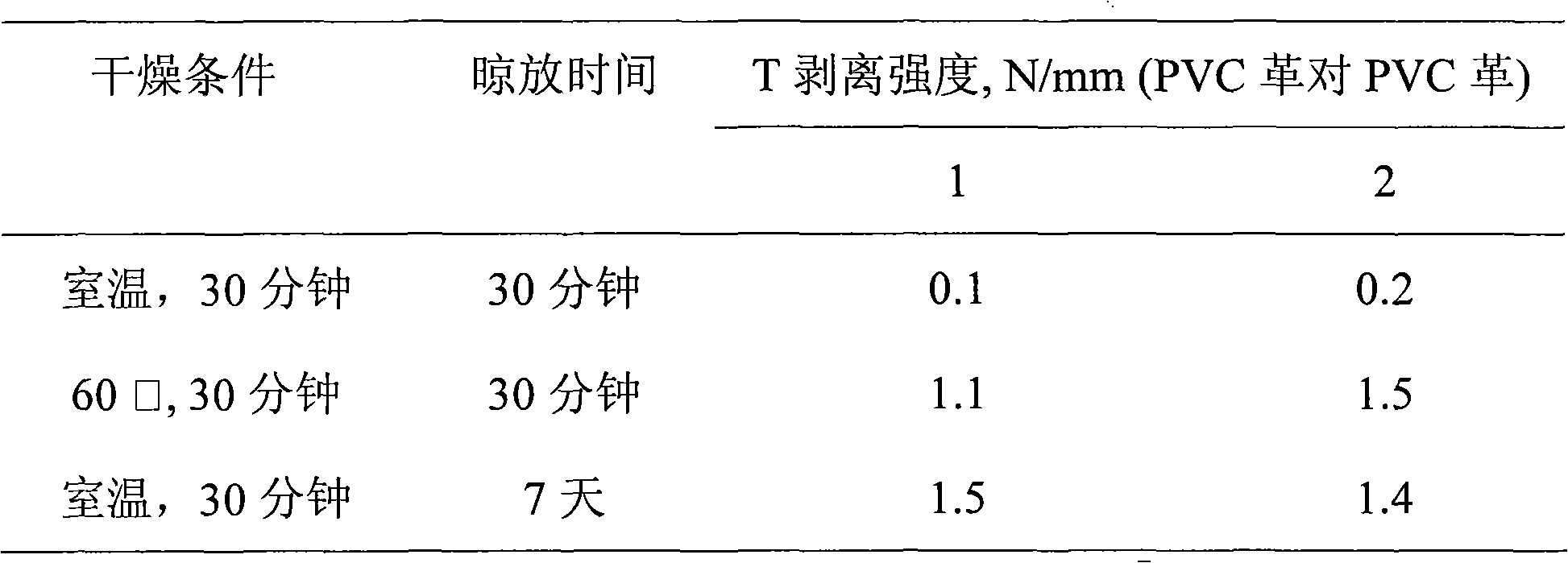

[0063] The neoprene latex adhesive prepared in this example is used for the bonding of PVC leather for bags, and the wet process is used for bonding.

[0064] The present embodiment neoprene latex type adhesive is made up of each component of following mass percentage:

[0065] Neoprene latex (Dispercoll C84 of Bayer company) 40%, styrene-acrylic emulsion 53%, commercially available rosin resin emulsion 6%, sodium lauryl sulphate 0.2%, mass percent concentration is 50% antioxidant 264 aqueous solution 0.1% 0.2% of zinc oxide aqueous solution with a concentration of 50% by mass, 0.3% of glycine with a concentration of 5% by mass, and 0.2% of thickener hydroxymethyl cellulose. The mass percentage is the percentage of the total mass of the adhesive weighed.

[0066] Wherein the preparation method of styrene-acrylic emulsion, its detailed steps are as follows: (1) each monomer that weighs following mass percent: butyl acrylate 50%, styrene 20%, methyl methacrylate 10%, isooctyl a...

Embodiment 3

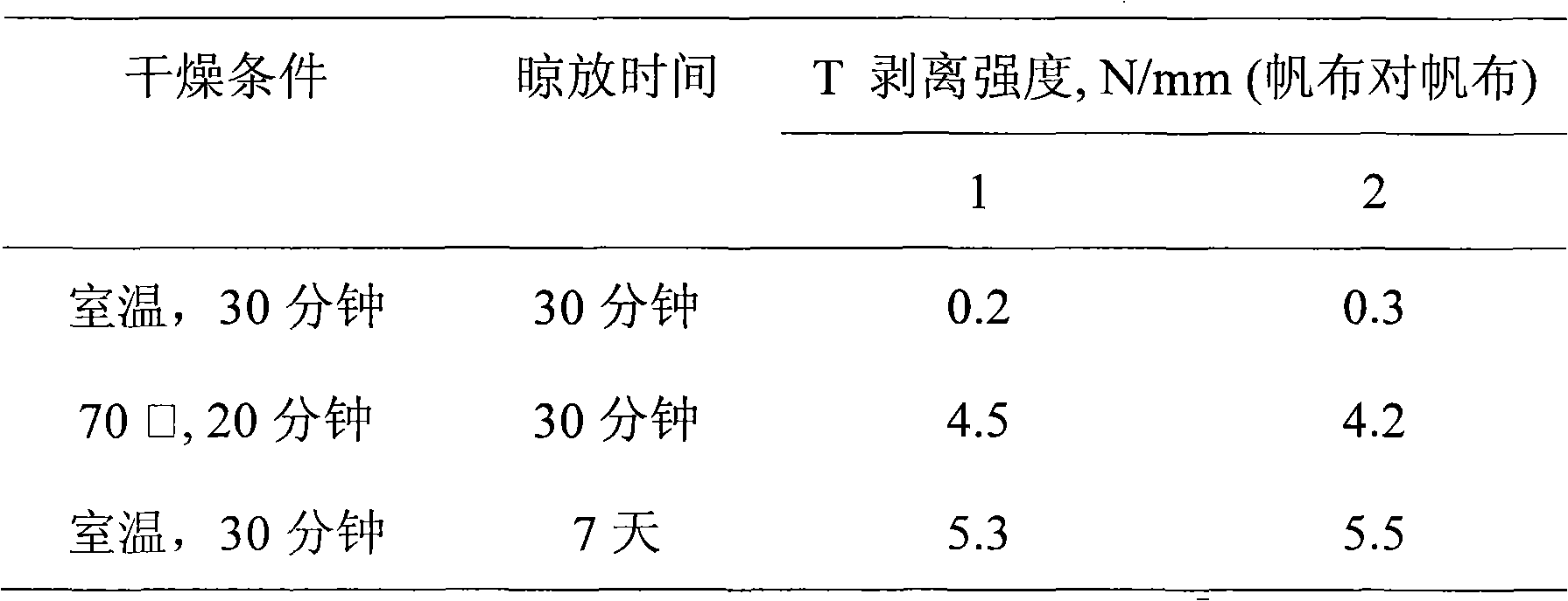

[0078] The neoprene latex adhesive prepared in this example is used for the bonding of canvas for bags, and is bonded by a wet process.

[0079] The present embodiment neoprene latex type adhesive is made up of each component of following mass percentage:

[0080] Neoprene latex (Dispercoll C84 of Bayer company) 30%, styrene-acrylic emulsion 58%, commercially available rosin resin emulsion 10.8%, sodium lauryl sulfate 0.3%, mass percent concentration is 50% antioxidant 264 aqueous solution 0.1% 0.2% of zinc oxide aqueous solution with a concentration of 50% by mass, 0.2% of glycine with a concentration of 5% by mass, and 0.4% of thickener hydroxymethyl cellulose. The mass percentage is the percentage of the total mass of the adhesive weighed.

[0081] Wherein the preparation method of styrene-acrylic emulsion is with embodiment 1.

[0082] According to the above formula, the neoprene latex adhesive was prepared by using the preparation method of Example 1. The performance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com