Corrosion-resistant high-pressure hose and production method thereof

A high-pressure hose, corrosion-resistant technology, applied in hoses, chemical instruments and methods, pipes, etc., can solve problems such as restricting the use range and service life of hoses, poor corrosion resistance and weak impact resistance of inner pipes, etc. Achieve the effect of improving service life, corrosion resistance, and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

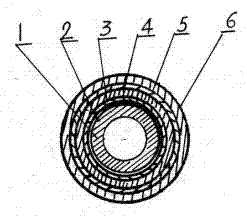

[0011] Example 1, such as figure 1 As shown, the present invention includes an inner tube layer 1, a steel wire reinforcement layer 3, a middle rubber layer 4 and an outer rubber layer 6, and is characterized in that the inner tube layer is an inner tube layer of hydrogenated nitrile rubber, and the outer layer of the inner tube layer of hydrogenated nitrile rubber is coated There is an aramid cloth layer 2, the aramid cloth layer is wound or braided steel wire reinforcement layer, the steel wire reinforcement layer is a medium rubber layer, the middle rubber layer is a medium rubber adhesive layer, and the medium rubber adhesive layer is connected with a wound or braided steel wire reinforcement layer Integral 5, the outermost outer rubber layer is a protective layer.

[0012] In consideration of further enhancing the impact resistance of the hose and improving the strength and flexibility of the hose, in this embodiment the outer rubber protective layer is also covered with ...

Embodiment 2

[0017] Example 2, the hydrogenated nitrile rubber inner rubber tube layer is formulated from the following components and weight ratios, semi-saturated hydrogenated butylnitrile 4367: highly saturated hydrogenated butylnitrile 3904: carbon black N330: carbon black N660: dioctyl Grease: zinc oxide: stearic acid: coumarone: dispersing flow aid ADD-212: antiaging agent mb: antiaging agent RD: peroxide vulcanizing agent DCO-40: accelerator TMTD: sulfur = 16:4:6:8 :1:1.1:01:2:0.3:0.3:0.35:1.3:0.4:0.2.

[0018] The middle rubber adhesive layer is formulated from the following components and weight ratios, neoprene CR-322: natural rubber NR-N41: zinc oxide: magnesium oxide: stearic acid SA: carbon black N660: dioxide Silicon: Silica: Anti-Armor: Anti-aging agent BLE: Adhesive AS-88: Sulfur: Accelerator DM=16:5:1.1:0.7:0.35:4:3:5:0.4:0.2:0.75:0.05: 0.05.

[0019] The outer rubber protection layer is prepared from the following components and weight ratio: Neoprene CR-322: Natural ru...

Embodiment 3

[0020] Example 3, the hydrogenated nitrile rubber inner rubber tube layer is formulated from the following components and weight ratios, half-saturated hydrogenated butylnitrile 4367: highly saturated hydrogenated butylnitrile 3904: carbon black N330: carbon black N660: dioctyl Grease: zinc oxide: stearic acid: coumarone: dispersion flow aid ADD-212: antiaging agent mb: antiaging agent RD: peroxide vulcanizing agent DCO-40: accelerator TMTD: sulfur = 16:5:4:9 :1.1:0.9:0.2:2.5:0.1:0.35:0.4:1.1:0.5:0.3.

[0021] The middle rubber adhesive layer is formulated from the following components and weight ratios, neoprene CR-322: natural rubber NR-N41: zinc oxide: magnesium oxide: stearic acid SA: carbon black N660: dioxide Silicon: Silica: Anti-Armor: Anti-aging agent BLE: Adhesive AS-88: Sulfur: Accelerator DM=16:6:0.9:0.8:0.4:2:4:6:0.2:0.3:0.8:0.03: 0.06.

[0022] The outer rubber protection layer is prepared from the following components and weight ratio: Neoprene CR-322: Natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com