Flame retardant wallpaper and preparation method thereof

A wallpaper, flame-retardant technology, applied in the field of interior decoration, can solve problems such as inability to meet fire resistance, achieve the effect of suitable for large-scale production, avoid metal flame retardants, excellent economic value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

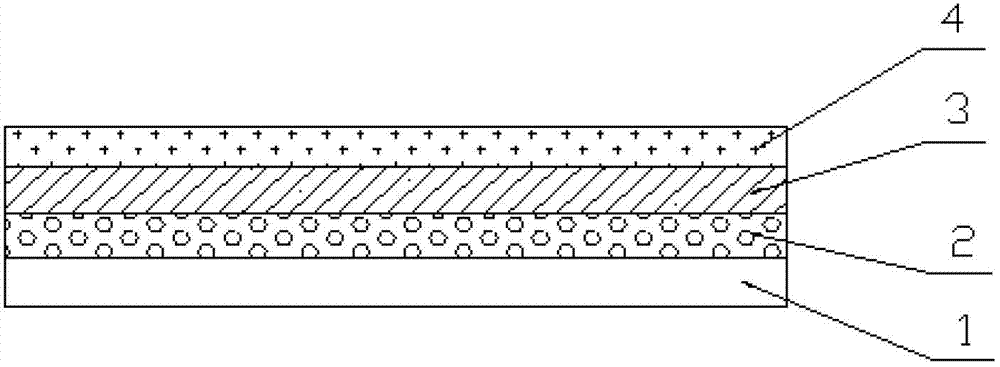

Image

Examples

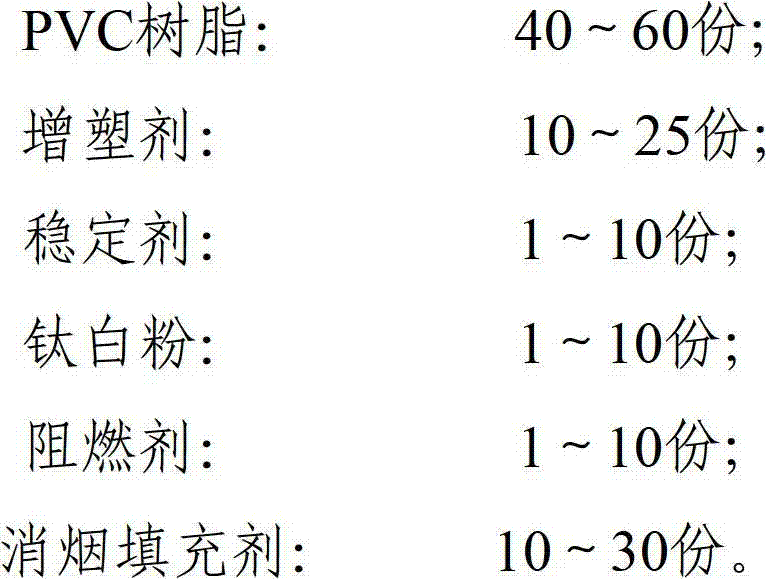

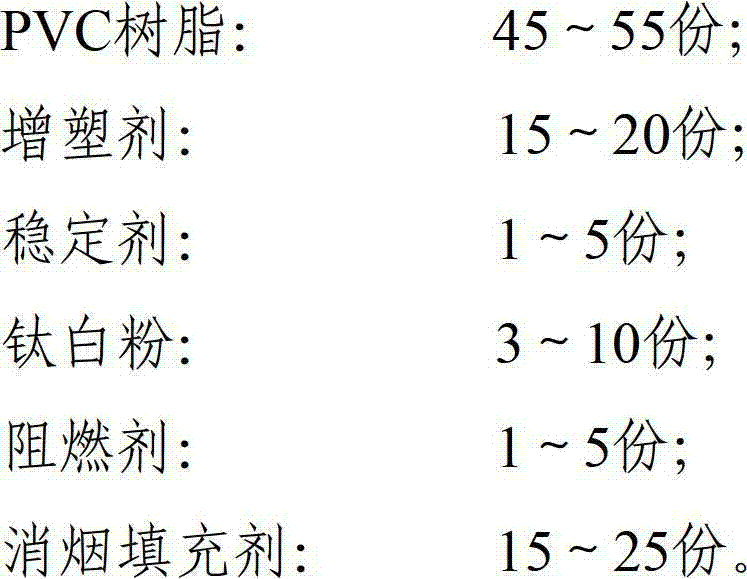

Embodiment 1

[0029] Ingredients for the PVC layer: PVC resin QS-1000F 50%, DOP plasticizer 17%, Plastistab 4000 barium-calcium-zinc composite stabilizer (OMG company in the United States) 2%, titanium dioxide 7%, organic nitrogen and phosphorus by weight percentage Intumescent flame retardant KY2303 (Jinan Taixing Fine Chemical Co., Ltd.) 4%, modified aluminum hydroxide ATH-1000 (Zhengzhou Fulong Chemical Company, 1000 mesh) 20%.

[0030] The manufacturing process of the wallpaper is as follows:

[0031] (1) First, mix and stir PVC resin, DOP plasticizer and barium-calcium-zinc composite stabilizer evenly, and then add titanium dioxide, flame retardant and modified aluminum hydroxide to make a mixed paste under stirring.

[0032] (2) Form the mixed paste obtained in step (1) into 300-400g / m by calender 2 PVC film, under the condition of 170℃, 70m / min and 40g / m 2 The grid pure cotton cloth substrate is compounded to form a semi-finished wallpaper.

[0033] (3) Perform mechanical calender...

Embodiment 2

[0036] Ingredients for PVC layer: PVC paste resin PSM-3160%, DINP plasticizer 13%, Plastistab 4000 barium-calcium-zinc composite stabilizer 3%, titanium dioxide 6%, organic nitrogen and phosphorus intumescent flame retardant in weight percentage KY230 33%, 500 mesh titanate coupling agent modified aluminum hydroxide 15%.

[0037] The manufacturing process of the wallpaper is as follows:

[0038] (1) First, mix and stir PVC resin, DINP plasticizer, and barium-calcium-zinc composite stabilizer evenly, and then add titanium dioxide, flame retardant, and modified aluminum hydroxide to make a mixed paste under stirring.

[0039] (2) Put the mixed paste obtained in step (1) through the coating machine at 85g / m 2 Coated a layer of 265-365g / m on the non-woven paper substrate 2 The PVC paste is heated and plasticized at 180°C and 50m / min to form a semi-finished wallpaper.

[0040] (3) Print and emboss the obtained semi-finished wallpaper to form a new type of flame-retardant wallpap...

Embodiment 3

[0043] Ingredients for the PVC layer: PVC resin QS-1000F 42%, DOP plasticizer 20%, Plastistab 3000 calcium-zinc composite stabilizer 5%, titanium dioxide 8.5%, organic nitrogen and phosphorus intumescent flame retardant KY2303 in weight percentage 4.5%, 20% of 2000 mesh aluminate coupling agent modified aluminum hydroxide.

[0044] The manufacturing process of the wallpaper is as follows:

[0045] (1) First, mix and stir PVC resin, DOP plasticizer and calcium-zinc composite stabilizer evenly, and then add titanium dioxide, flame retardant and modified aluminum hydroxide to make a mixed paste under stirring.

[0046] (2) Form the mixed paste obtained in step (1) into 300-400g / m by calender 2 PVC film, at 170°C, 70m / min and 40g / m 2 The blended fabric substrate is compounded to form a semi-finished wallpaper.

[0047] (3) Mechanically calendering, printing and embossing the obtained wallpaper semi-finished products to form a new type of flame retardant wallpaper

[0048]The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com