Foam-paperboard laminates, articles incorporating same and methods of making the same

a technology of foam paperboard and laminates, applied in the field of foam paperboard laminates, can solve the problem that the foam quality cannot be obtained using web speeds greater than about 300 feet per minute, and achieve the effect of higher speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0140] The following Examples are put forth so as to provide those of ordinary skill in the art with a complete disclosure and description of how the present invention is practiced, and associated processes and methods are constructed, used, and evaluated, and are intended to be purely exemplary of the invention and are not intended to limit the scope of what the inventors regard as their invention. Efforts have been made to ensure accuracy with respect to numbers (e.g., amounts, temperature, etc.) but some errors and deviations should be accounted for. Unless indicated otherwise, parts are parts by weight, temperature is as specified or is at ambient temperature, and pressure is at or near atmospheric.

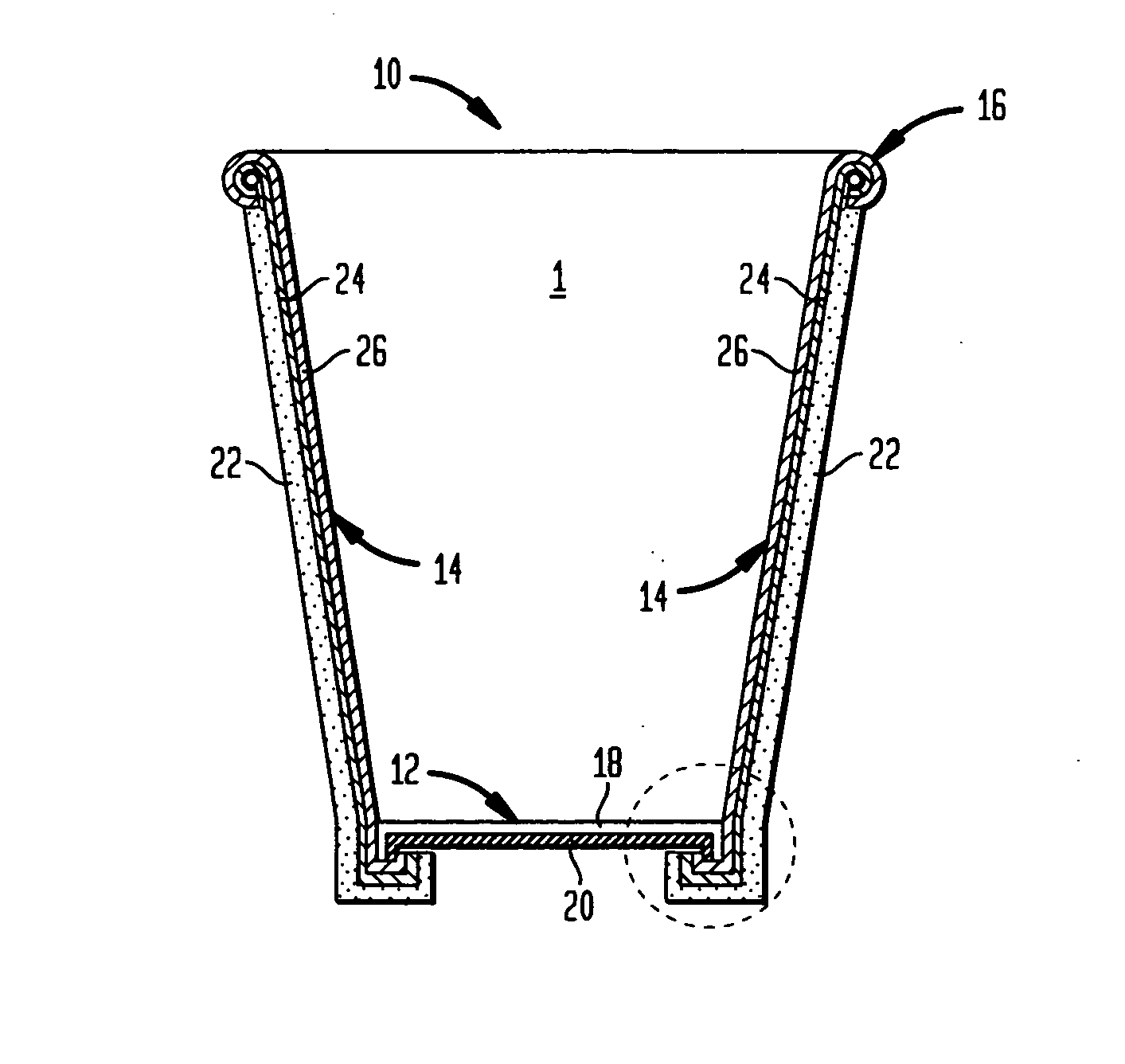

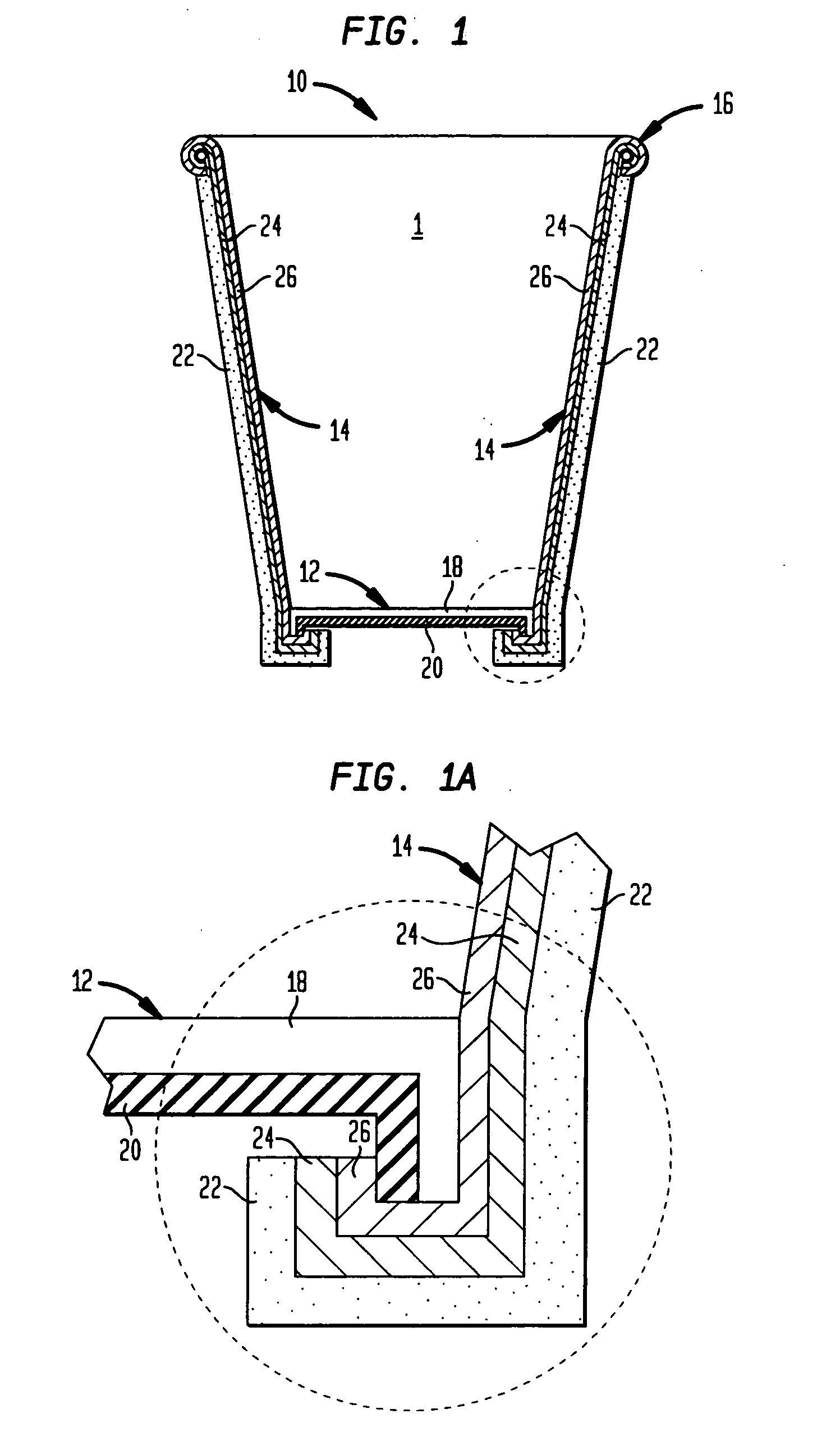

[0141] A. Preparation of Insulated Beverage Cups from Foam-Paperboard Laminates of the Present Invention

[0142] Utilizing generally the apparatus and procedures described above, a series of extrusion-coated LDPE paperboard samples were prepared and foamed in situ at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com