Circuit substrate and preparation method thereof

A circuit substrate, electronic-level technology, applied in circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problem of not considering signal delay and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

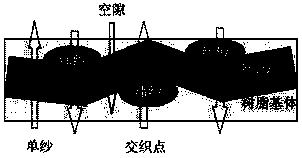

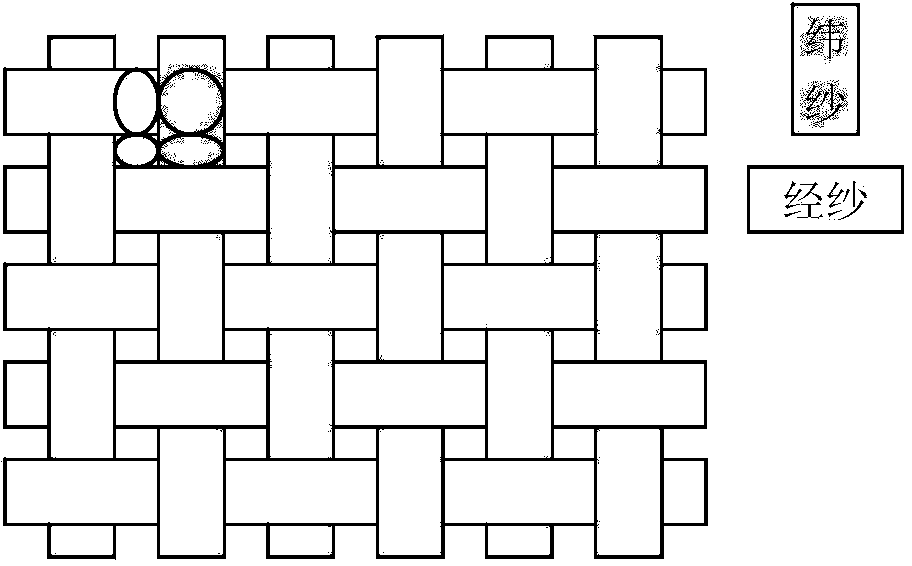

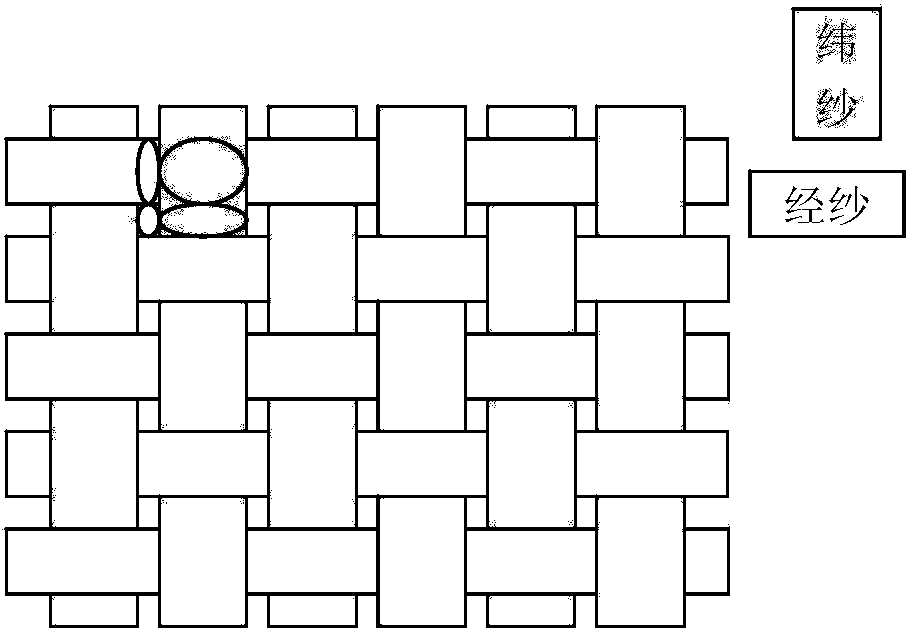

Method used

Image

Examples

Embodiment 1

[0096] Use E-type 1080 glass fiber cloth (mass per unit area is 46.8g / m 2 ) as a reinforcing material, the epoxy resin composition was dissolved in a solvent and then added with a filler as a pretreatment glue. Table 1 shows the composition of the glue formula and the physical properties of the circuit board. The steps for making the circuit board are as follows:

[0097] Step 1: Prepare pretreatment glue. Take a suitable container, add 40 parts by mass of epoxy resin composition, an appropriate amount of butanone solvent, stir for a certain period of time, then add 52 parts by mass of rutile titanium dioxide filler and 8 parts by mass of amorphous silica filler, and carry out Stir well, and emulsify and disperse to form the pretreatment glue. The Dk of the glue is 6.6.

[0098] Step 2: Prepare pretreated E-type glass fiber cloth. Use the above pretreatment glue to pre-impregnate the E-type glass fiber cloth, and dry the solvent after completion to obtain a pretreated glass...

Embodiment 2

[0102] Use E-type 1080 glass fiber cloth (mass per unit area is 46.8g / m 2 ) as a reinforcing material, the epoxy resin composition was dissolved in a solvent and then added with a filler as a pretreatment glue. Table 1 shows the composition of the glue formula and the physical properties of the circuit board. The steps for making the circuit board are as follows:

[0103] Step 1: Prepare pretreatment glue. Take a suitable container, add 42 parts by mass of epoxy resin composition, an appropriate amount of butanone solvent, stir for a certain period of time, then add 50 parts by mass of rutile titanium dioxide filler and 8 parts by mass of amorphous silica filler, and carry out Stir well, and emulsify and disperse to form the pretreatment glue, the glue Dk is 6.5.

[0104] Step 2: Prepare pretreated E-type glass fiber cloth. Use the above pretreatment glue to pre-impregnate the E-type glass fiber cloth, and dry the solvent after completion to obtain a pretreated glass fiber ...

Embodiment 3

[0108] Use E-type 1080 glass fiber cloth (mass per unit area is 46.8g / m 2 ) as a reinforcing material, the cyanate resin composition was dissolved in a solvent and then added with fillers as a pretreatment glue, the composition of the glue formula and the physical property data of the circuit board are shown in Table 1. The steps for making the circuit board are as follows:

[0109] Step 1: Prepare pretreatment glue. Take a suitable container, add 40 parts by mass of cyanate resin composition, an appropriate amount of butanone solvent, stir for a certain period of time, then add 54 parts by mass of rutile titanium dioxide filler and 6 parts by mass of amorphous silica filler, Thoroughly stir, emulsify and disperse to form the pretreatment glue, and the Dk of the glue is 6.5.

[0110] Step 2: Prepare pretreated E-type glass fiber cloth. Use the above pretreatment glue to pre-impregnate the E-type glass fiber cloth, and dry the solvent after completion to obtain a pretreated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com