Preparation method of wear-resistant super-hydrophobic nanometer titania coating

A nano-titanium dioxide and coating technology, which is applied in coatings, epoxy resin coatings, dyed organic silicon compounds, etc., can solve the problems of easy shedding of nanoparticles, poor adhesion between coating layers and internal bonding force, etc. Achieve the effect of improving protection ability, prolonging service life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

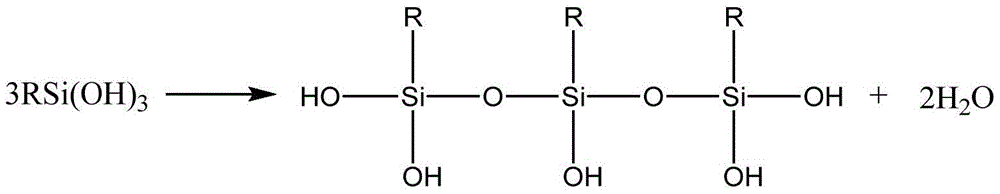

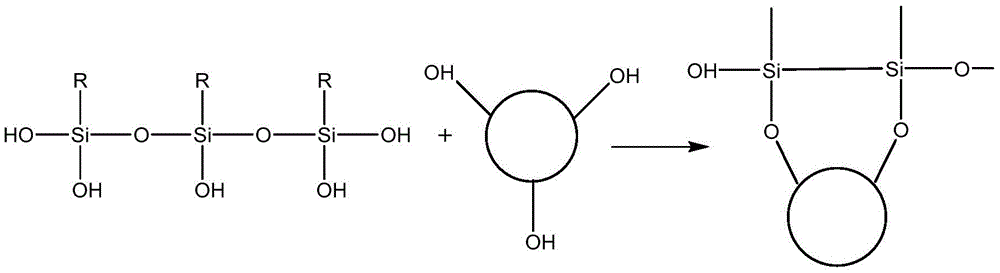

[0043] In the present invention, a method for preparing a wear-resistant superhydrophobic nano-titanium dioxide coating specifically comprises the following steps:

[0044] Step 1. Mix the silane coupling agent n-octyltriethoxysilane and ethanol (absolute ethanol) according to the mass ratio of 1:50, and use a temperature-controlled magnetic stirrer to fully heat and stir at 50°C for 2 hours. The stirring rate was 400r / min to obtain a solution;

[0045] Step 2, adding particle diameter to the above solution is rutile nano-titanium dioxide of 25nm, the mass ratio of rutile-type nano-titanium dioxide to ethanol is 0.5:10, and stirring for 1h under the condition of 400r / min with a magnetic stirrer at a stirring rate, so that The nanoparticles are fully contacted with the silane coupling agent, and finally dried at 50°C for 10 hours to obtain superhydrophobic nano-titanium dioxide powder;

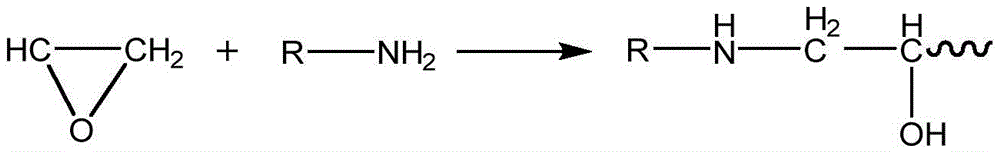

[0046] Step 3, mix E-42 epoxy resin and curing agent polyamide according to the ratio of 4...

Embodiment 2

[0053] In the present invention, a method for preparing a wear-resistant superhydrophobic nano-titanium dioxide coating specifically comprises the following steps:

[0054] Step 1. Mix the silane coupling agent vinyltriethoxysilane and ethanol (absolute ethanol) according to the mass ratio of 0.5:50, use a temperature-controlled magnetic stirrer to fully heat and stir at 30°C for 4 hours, and stir The speed is 200r / min, and the solution is obtained;

[0055] Step 2, add the rutile type nano-titanium dioxide that particle diameter is 40nm in above-mentioned solution, the mass ratio of rutile type nano-titanium dioxide and ethanol is 2:10, and be stirred 1h under the condition of 200r / min with magnetic stirrer at stirring rate, make The nanoparticles are fully contacted with the silane coupling agent, and finally dried at 30°C for 8 hours to obtain nano-titanium dioxide powder;

[0056] Step 3, mix E-44 epoxy resin and curing agent ethylenediamine according to the ratio of 1:1,...

Embodiment 3

[0061] The difference from Example 1 is that the silane coupling agent is a mixture of vinyltrimethoxysilane and p-styryltrimethoxysilane, wherein the mass ratio of the two is 1:1.

[0062] Detection: The sample uses a contact angle measuring instrument to measure the contact angle of the final coating, and it is found that the contact angle of water is about 150°, and the rolling angle is less than 5°, which shows that the obtained coating has excellent hydrophobic properties; We use the pull-off method to measure the interlayer adhesion between the coating and the substrate, and find that the adhesion is around 295psi; we use the sandpaper abrasion test to test the wear resistance of the coating, and find that the quality of the coating changes by 100± 10mg and the contact angle of water can still reach 150°, and the rolling angle is less than 5°, which shows that the prepared coating has excellent wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com