Medium-temperature baking type fluorine-carbon paint and its use method

A fluorocarbon paint, medium temperature technology, applied in the direction of coating, pretreatment of the surface, and the device for coating liquid on the surface, etc., can solve the problems of gaps, high energy consumption, etc., to improve production efficiency, reduce energy consumption, and beautiful coating The effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

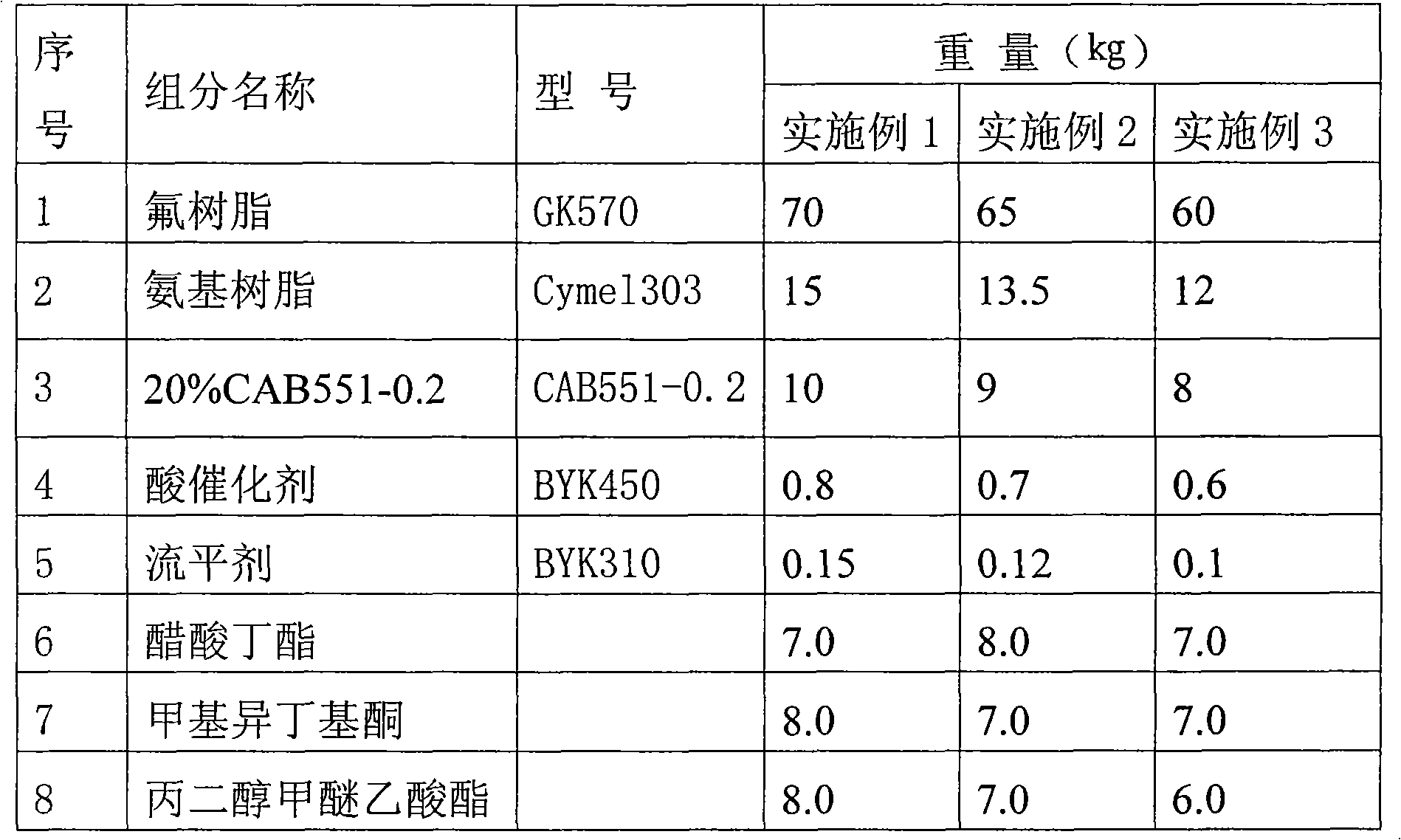

[0100] Preparation of medium-temperature baking type fluorocarbon varnish: Take fluororesin, 20% CAB551-0.2, and amino resin in the components according to the weight ratio shown in Example 1 in Table 1, stir and mix evenly at a low to medium speed, and then add the fluid Leveling agent, acid catalyst, butyl acetate, methyl isobutyl ketone, propylene glycol methyl ether acetate, mixed evenly at low to medium speed for 15-20 minutes, filtered through a 120-mesh filter after passing the inspection, and packaged to obtain Medium temperature baking fluorocarbon varnish.

[0101] Prepare the thinner supporting the fluorocarbon varnish according to the following components and weight ratio:

[0102] Xylene 50

[0103] Methyl isobutyl ketone 17

[0104] Propylene glycol methyl ether acetate 25

[0105] DBE 8,

[0106] Add the above four solvents into the production container according to the ratio, stir at a low speed for 5-10 minutes, filter through a 400-mesh filter, and pack t...

Embodiment 2

[0109] According to the weight ratio and components shown in Example 2 in Table 1, prepare and use the medium temperature baking type fluorocarbon varnish and supporting diluent according to the method of Example 1 to obtain the fluorocarbon varnish film. Routine performance test results (dry film thickness 20-26μm, recoated total dry film thickness 30-40μm) are shown in Table 6.

Embodiment 3

[0111] According to the weight ratio and components shown in Example 3 in Table 1, prepare and use the medium temperature baking type fluorocarbon varnish and supporting diluent according to the method of Example 1 to obtain the fluorocarbon varnish film. Routine performance test results (dry film thickness 20-26μm, recoated total dry film thickness 30-40μm) are shown in Table 6.

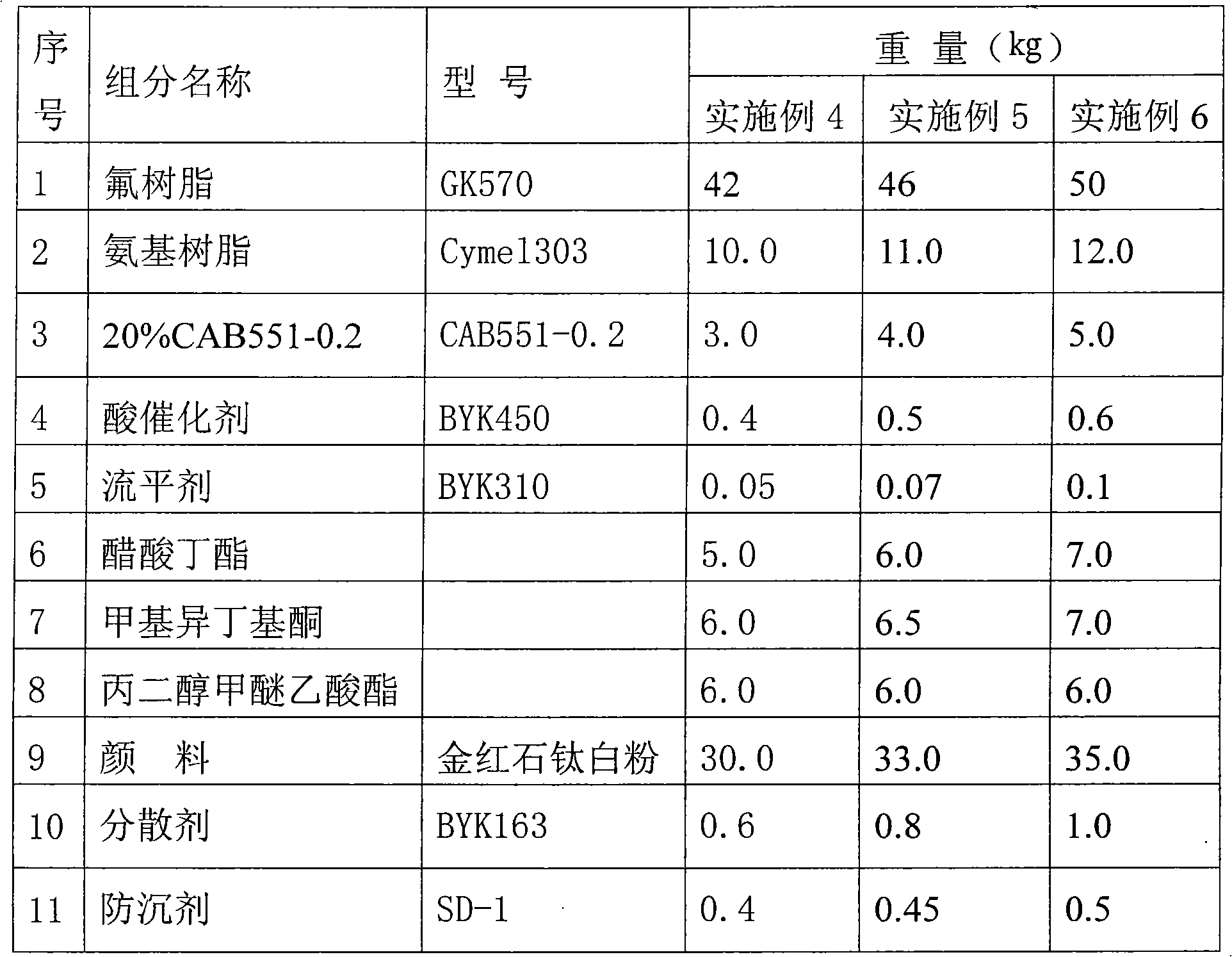

[0112] Table 2 shows the components and weight ratios of the medium-temperature baking type fluorocarbon paint high-gloss white paint prepared in Examples 4-6.

[0113] Table II

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com