Ternary cementitious system stucco finish, and application method thereof

A facing mortar and system technology, applied in the field of building materials, can solve the problems of affecting the factory production efficiency, affecting the aesthetic decoration effect, and poor stain resistance, so as to improve the early strength and volume stability, and excellent performance indicators , Shrinkage cracking resistance and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: A kind of ternary gelling system facing mortar, according to white portland cement 100, sulfoaluminate cement 40, gypsum 25, slag fine powder 20, zeolite powder 15, ethylene-vinyl acetate-vinyl laurate Ternary copolymerization redispersible latex powder 12, hydroxyethyl methylcellulose 0.8, sodium laurate sulfate air-entraining agent 0.12, polydimethylsiloxane defoamer 0.35, polysiloxane water repellent 1.1 , Thixotropic agent 4, iron oxide inorganic pigment 4, quartz sand 400 weight ratio prepared. Add water according to 21% of the total weight of the facing mortar, add the ingredients according to the above-mentioned order and stir evenly to get the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0050] Embodiment 2: A kind of ternary gelling system facing mortar, according to white Portland cement 100, sulfoaluminate cement 30, gypsum 20, slag fine powder 30, zeolite powder 10, ethylene-vinyl acetate-vinyl laurate Ternary copolymerization redispersible latex powder 16, hydroxyethyl methylcellulose 1.2, sodium laurate sulfate air-entraining agent 0.2, polydimethylsiloxane defoamer 0.5, polysiloxane water repellent 0.8 , Thixotropic agent 5.5, iron oxide inorganic pigment 5, quartz sand 480 weight ratio prepared. Add water according to 23% of the total weight of the facing mortar, add the ingredients according to the above-mentioned order and stir evenly to get the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0051] Embodiment 3: a kind of ternary gelling system facing mortar, according to white portland cement 100, sulfoaluminate cement 18, gypsum 18, slag fine powder 15, zeolite powder 9, latex powder 15, cellulose ether 1.6, Air entraining agent 0.4, defoamer 0.4, water repellent 1.7, thixotropic agent 6.5, inorganic pigment 6.5, quartz sand 560 weight ratio. Add water according to 20.5% of the total weight of the facing mortar, add the ingredients according to the above-mentioned order and stir evenly to get the desired product. The performance test results are shown in Table 1.

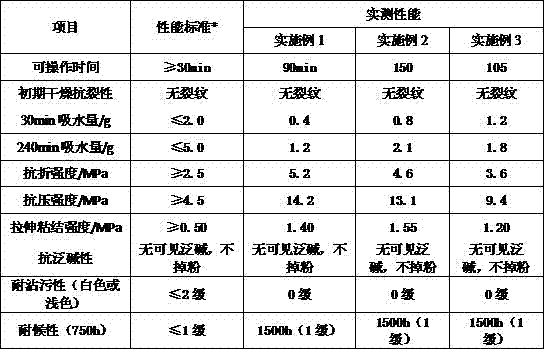

[0052] Table 1 Performance test results of ternary cement system facing mortar

[0053]

[0054] *E-type performance index in the national industry standard "Wall Finishing Mortar" JC / T1024-2007.

[0055] It can be seen from the above examples that the ternary cementitious system facing mortar proposed by the present invention can be formulated into corresponding products according to the require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com