Lightweight leveling putty and preparation method thereof

A light and heavy calcium carbonate technology, applied in filling slurry and other directions, can solve the problems of high water absorption, hollow drum cracking, building energy consumption, etc., achieves a simple preparation method, is convenient for industrial production, and solves the problem of masonry cold bridge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

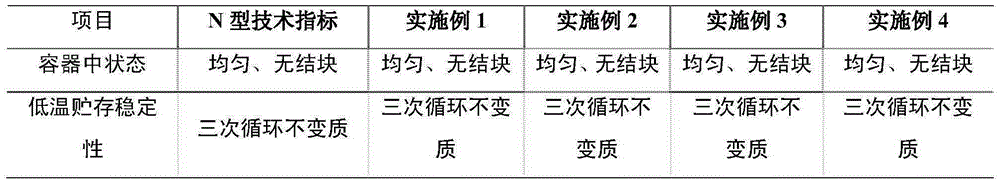

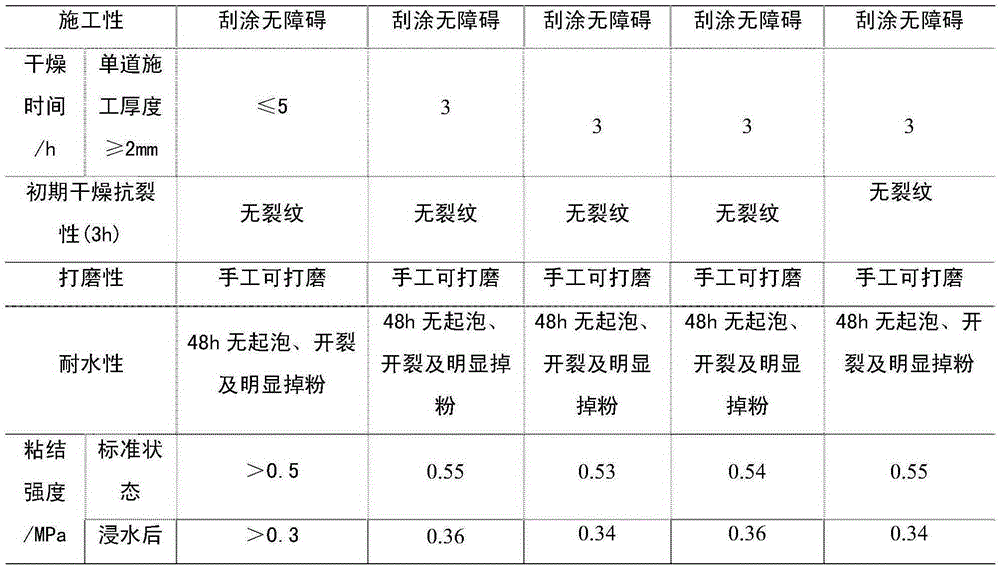

Examples

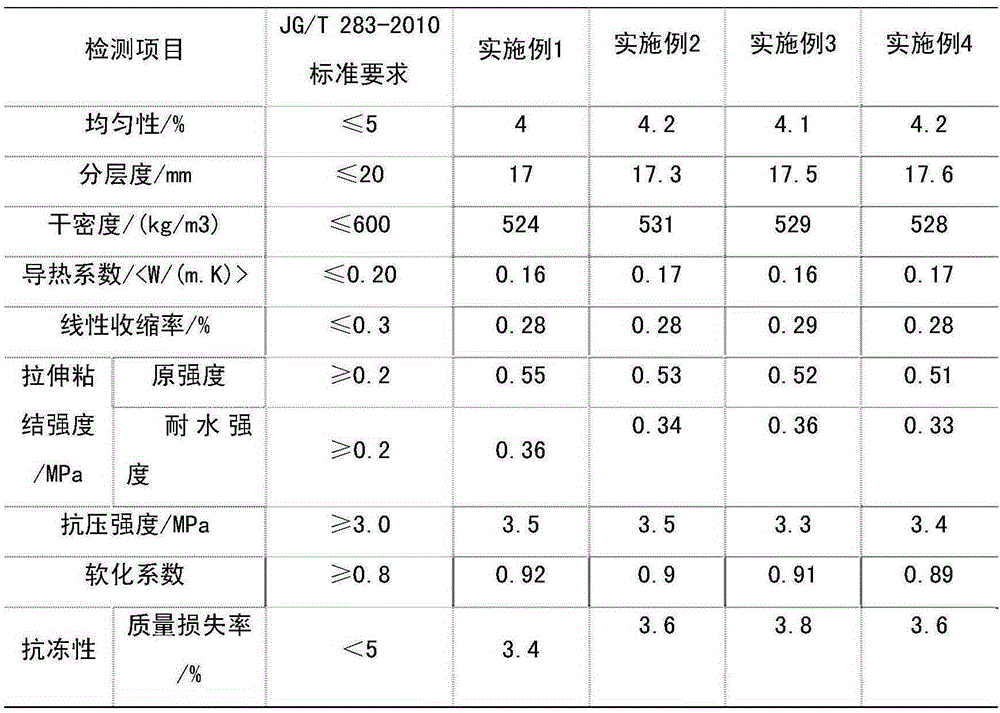

Embodiment 1

[0023] A lightweight leveling putty, which comprises the following components in parts by weight: 10 parts of white Portland cement, 25 parts of desulfurized gypsum powder, 15 parts of closed-cell perlite, 40 parts of heavy calcium carbonate, 6 parts of talcum powder, 3 parts of renewable dispersible latex powder, 0.5 part of cellulose, 0.2 part of starch ether and 0.3 part of air-entraining agent.

Embodiment 2

[0025] A lightweight leveling putty, which comprises the following components in parts by weight: 25 parts of white Portland cement, 15 parts of desulfurized gypsum powder, 10 parts of closed-cell perlite, 45 parts of heavy calcium carbonate, 3.4 parts of talcum powder, 1 part of renewable dispersible latex powder, 0.4 part of cellulose, 0.1 part of starch ether and 0.1 part of air-entraining agent.

Embodiment 3

[0027] A lightweight leveling putty, which comprises the following components in parts by weight: 17 parts of white Portland cement, 23 parts of desulfurized gypsum powder, 14 parts of closed-cell perlite, 38.4 parts of heavy calcium carbonate, 5 parts of talcum powder, 2 parts of renewable dispersible latex powder, 0.3 part of cellulose, 0.1 part of starch ether and 0.2 part of air-entraining agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com