Environment-friendly high-adhesion-stress special putty for ceramic tile surfaces and preparation method thereof

A high-adhesive, environmentally-friendly technology, applied in the field of coating products, can solve the problems of high cost and inability to completely solve the problem, achieve the effect of improving the bonding strength, expanding the variety and scope of application, and having broad prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

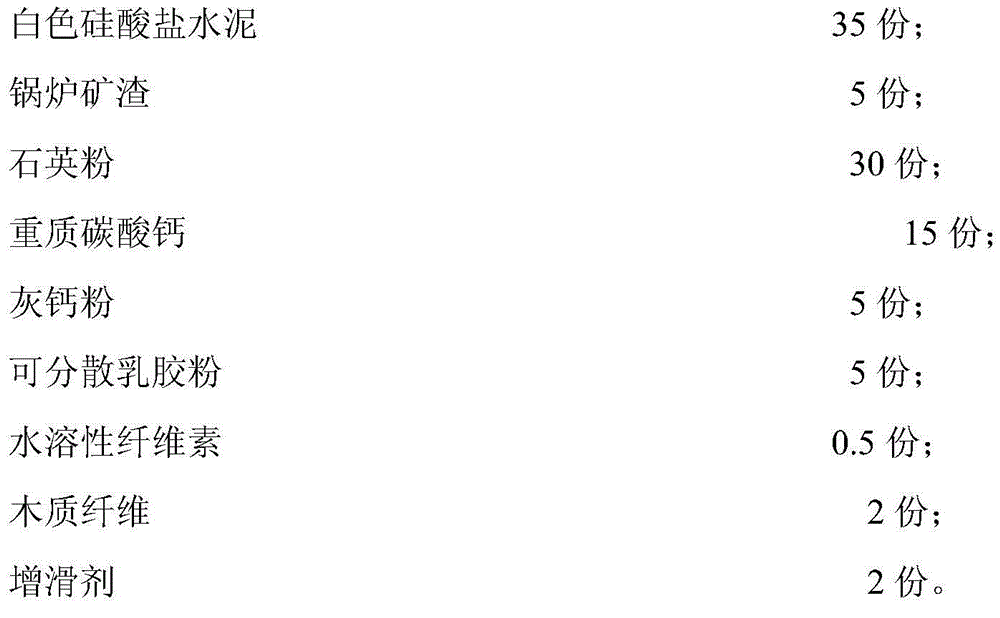

[0043] The specific weight portion of the environmental protection high cohesive tile surface special putty that present embodiment provides is as follows:

[0044]

[0045] in,

[0046] The white Portland cement is No. 32.5 white Portland cement provided by Mingyue Chemical Co., Ltd.;

[0047] Boiler slag is steelmaking pig iron slag provided by Maanshan Iron and Steel Group;

[0048] Quartz powder is 40-80 mesh quartz sand and 80-160 mesh quartz sand provided by Yongxing Stone Building Co., Ltd., the ratio of the two is 4:1;

[0049] Ground calcium carbonate is 400 mesh heavy calcium carbonate provided by Anzhibang;

[0050] Ash calcium powder is 400 mesh ash calcium powder provided by Anzhibang;

[0051] Dispersible latex powder is vinyl acetate and ethylene copolymer rubber powder and vinyl acetate and higher fatty acid ethylene resin copolymer rubber powder provided by Nanjing Gutian Chemical Co., Ltd.;

[0052] The water-soluble cellulose is hydroxyethyl methyl ce...

Embodiment 2

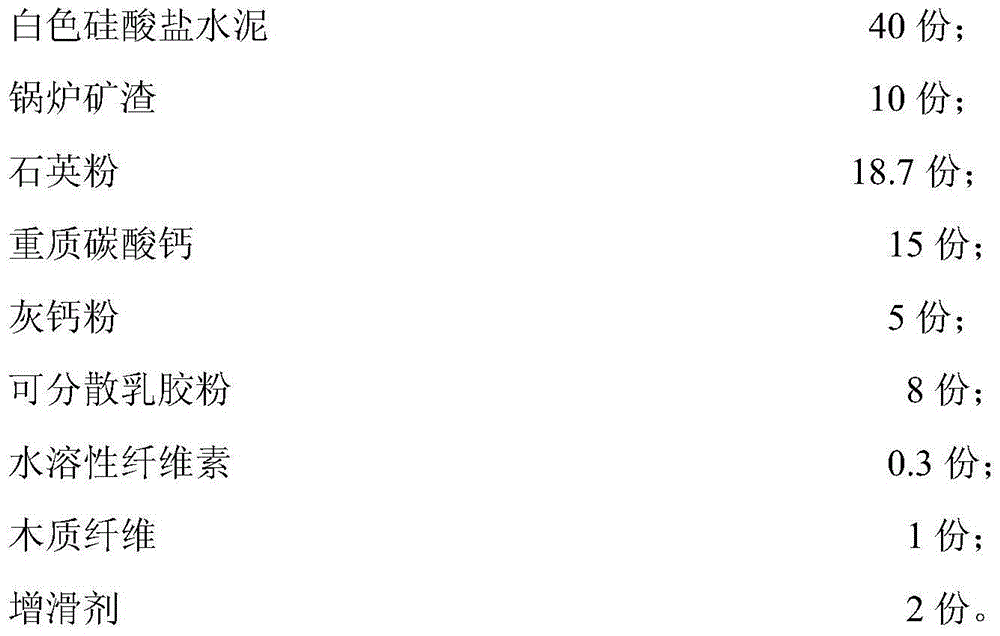

[0060] The specific weight portion of the environmental protection high cohesive tile surface special putty that present embodiment provides is as follows:

[0061]

[0062] A kind of preparation method of special putty for ceramic tile surface of environmental protection high cohesion is:

[0063] (1), take various raw materials respectively by above-mentioned weight;

[0064] (2), open the mixer, dust collector;

[0065](3) Add 35% water to the above-mentioned raw materials and mix them until they are in the shape of putty.

Embodiment 3

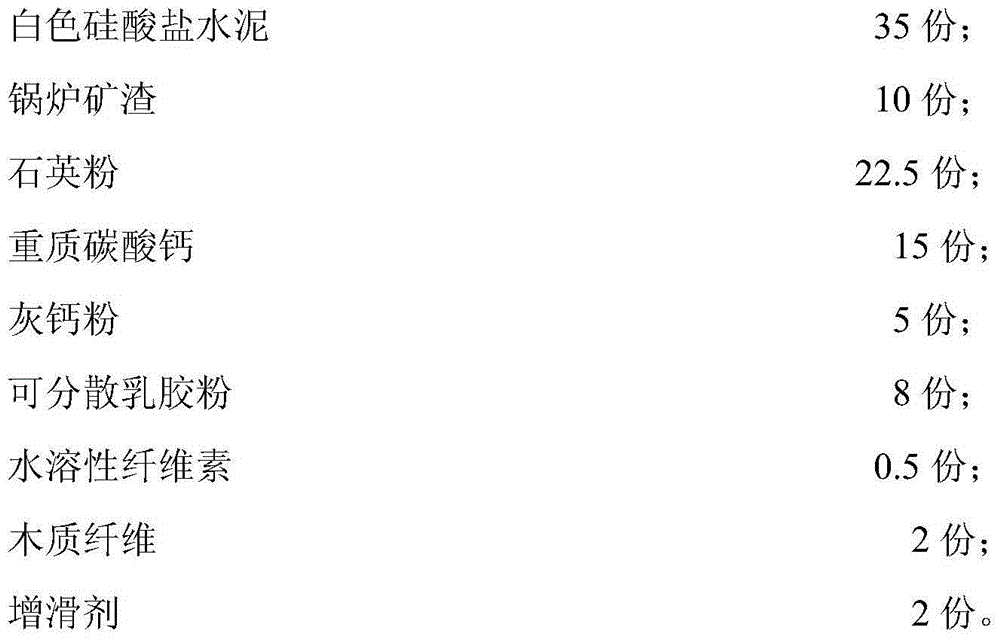

[0067] An environment-friendly high-adhesion special putty for ceramic tile surfaces, the specific weight parts of the raw materials are as follows:

[0068]

[0069] A kind of preparation method of special putty for ceramic tile surface of environmental protection high cohesion is:

[0070] (1), take various raw materials respectively by above-mentioned weight;

[0071] (2), open the mixer, dust collector;

[0072] (3), when the mixer is at a rotating speed of 1000r / min, add 25% water to the above-mentioned raw materials and mix and stir for 35 minutes. After releasing at least 50 parts by weight of the bottom material, continue to stir for 10 minutes until the mixture is evenly putty-like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com