Waterproof slurry with sterilization function for toilet bath room decoration surfaces

A waterproof slurry and bathroom technology, which is applied in the direction of cement coating, biocide-containing paint, sustainable waste treatment, etc., can solve problems such as cracking construction, efflorescence of facing mortar, difficulty, etc., and achieve extended shelf life and decorative effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

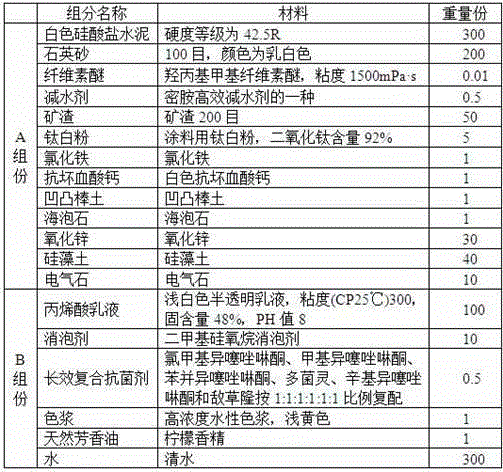

[0065] Example 1 Prepare the waterproof slurry with bactericidal function for the toilet and bathroom decoration of the present invention according to the following formula:

[0066] (1) The formula is shown in the table below:

[0067]

[0068] (2) Preparation:

[0069] Accurately weigh each component according to the formula, and manually stir and mix in advance to form a uniform component A system and component B system. According to the powder-to-liquid ratio of component A: component B = 1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 5 minutes until it is evenly mixed.

[0070] The above-mentioned waterproof slurry that can be used for colored finishes is tested, and the indicators are shown in the following table, all of which meet the JC / T2090-2011 polymer cement waterproof slurry standard:

[0071] .

Embodiment 2

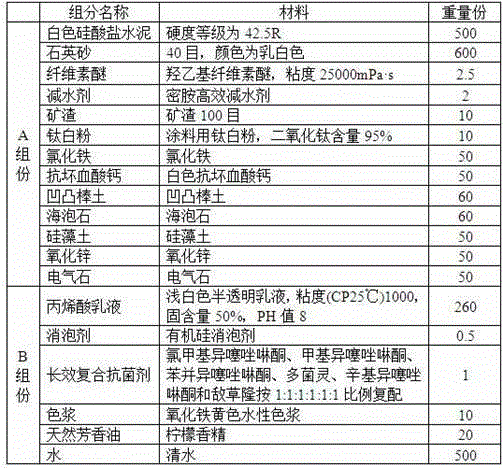

[0072] Example 2 Prepare the waterproof slurry with bactericidal function for the toilet and bathroom decoration of the present invention according to the following formula:

[0073] (1) The formula is shown in the table below:

[0074]

[0075] (2) Preparation: Accurately weigh each component according to the formula, and manually stir and mix in advance to form a uniform component A system and component B system. According to the powder-to-liquid ratio of component A: component B = 1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 10 minutes until it is evenly mixed.

Embodiment 3

[0076] Example 3 Prepare the waterproof slurry with bactericidal function for the toilet and bathroom decoration of the present invention according to the following formula:

[0077] (1) The formula is shown in the table below:

[0078]

[0079] (2) Preparation: Accurately weigh each component according to the formula, and manually stir and mix in advance to form a uniform component A system and component B system. According to the powder-to-liquid ratio of component A: component B = 1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 5 minutes until it is evenly mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com