Decorative concrete for building external envelope structure and preparation method thereof

A technology for decorating concrete and enclosure structures, which is applied in the field of building material decoration, can solve the problems of unsuitable decoration, easy construction and high strength and high durability, and achieve the improvement of mechanical properties and durability, formula optimization, and production The effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

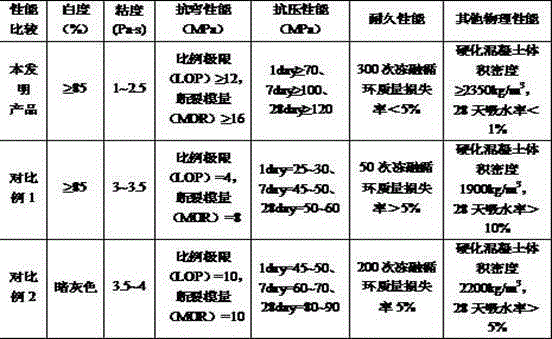

Examples

Embodiment example 1

[0032] (1) Weigh 40kg of silica fume, 40kg of acicular wollastonite powder mixture, 2kg of polydimethylsiloxane, 3kg of high-carbon alcohol fatty acid ester, 10kg of powdered polycarboxylate superplasticizer, 2kg of vinyl acetate according to the formula ratio Copolymer resin of ester and ethylene, 2kg polyethylene wax, 1kg toner, mixed for 10min to obtain uniform decorative powder;

[0033] (2) Weigh 60kg of water, 3kg of polycarboxylate water reducer, 3kg of polycarboxylate slump retaining agent, and 1kg of polyoxypropylene oxide glyceryl ether according to the proportion of the formula, mix them evenly, and stir for 1 minute to obtain a solution;

[0034] (3) Put 100kg of low-viscosity decorative powder prepared according to step (1), 167kg of white Portland cement, and 167kg of ultra-fine discontinuous graded sand in a self-made mixing container, and stir at a speed of 30r / min for 5min to make it uniform Mix, put in 80% of the solution prepared according to step (2), stir ...

Embodiment example 2

[0037](1) Weigh 46kg of superfine metakaolin, 50kg of nano-active calcium carbonate mixture, 0.05kg of high-carbon alcohol fatty acid ester, 0.05kg of polyoxyethylene polyoxypropanolamine ether, and 1kg of powder polycarboxylate water-reducing Agent, 1kg ethylene, vinyl chloride and lauryl vinyl ester ternary copolymer resin, 1kg sodium cetylbenzenesulfonate, 0.9kg toner, mixed for 10min to obtain a uniform decorative powder;

[0038] (2) Weigh 97kg of water, 1.4kg of polycarboxylate water reducer, 1kg of polycarboxylate slump retaining agent, and 1kg of polyoxypropylene oxide glyceryl ether according to the proportion of the formula, mix them evenly, and stir for 2 minutes to obtain a solution;

[0039] (3) Put 100kg of low-viscosity decorative powder prepared according to step (1), 500kg of white Portland cement, and 400kg of ultra-fine discontinuous graded sand in a self-made mixing container, and stir at a speed of 50r / min for 5min to make it uniform Mix, put in 80% of the...

Embodiment example 3

[0042] (1) Weigh 42kg of limestone powder, 40kg of superfine silica powder, 1kg of polyoxyethylene polyoxypropanolamine ether, 1kg of polydimethylsiloxane, and 2kg of powdered polycarboxylate superplasticizer according to the formula ratio. 5kg of vinyl acetate, ethylene and higher fatty acid vinyl ester ternary copolymer resin, 3kg of stearate, 6kg of toner, mixed for 10min to obtain a uniform decorative powder;

[0043] (2) Weigh 64.94kg of water, 10kg of polycarboxylate superplasticizer, 5kg of naphthalene-based slump-retaining agent, and 0.1kg of polyoxypropylene oxide glyceryl ether according to the proportion of the formula, mix them evenly, and stir for 2 minutes to obtain a solution;

[0044] (3) Put 100kg of low-viscosity decorative powder prepared according to step (1), 300kg of white Portland cement, and 300kg of ultra-fine discontinuous graded sand in a self-made mixing container, and stir at a speed of 40r / min for 5min to make it uniform Mix, put in 80% of the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com