A kind of Fusarium strain and method for producing d-pantolactone hydrolase by fermentation

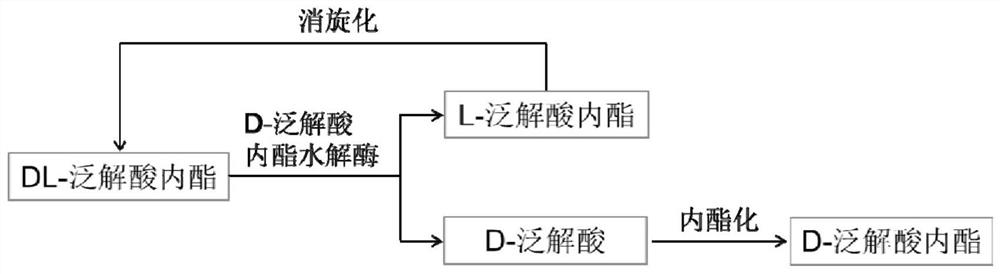

A pantolactone and fusarium technology, which is applied in the field of microbial strain screening and fermentation, can solve the problems of unfavorable environmental protection, difficult separation of impurities, and high cost of chemical splitting agents, and achieves reduction of production costs, improvement of enzyme activity, and economical benefits. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

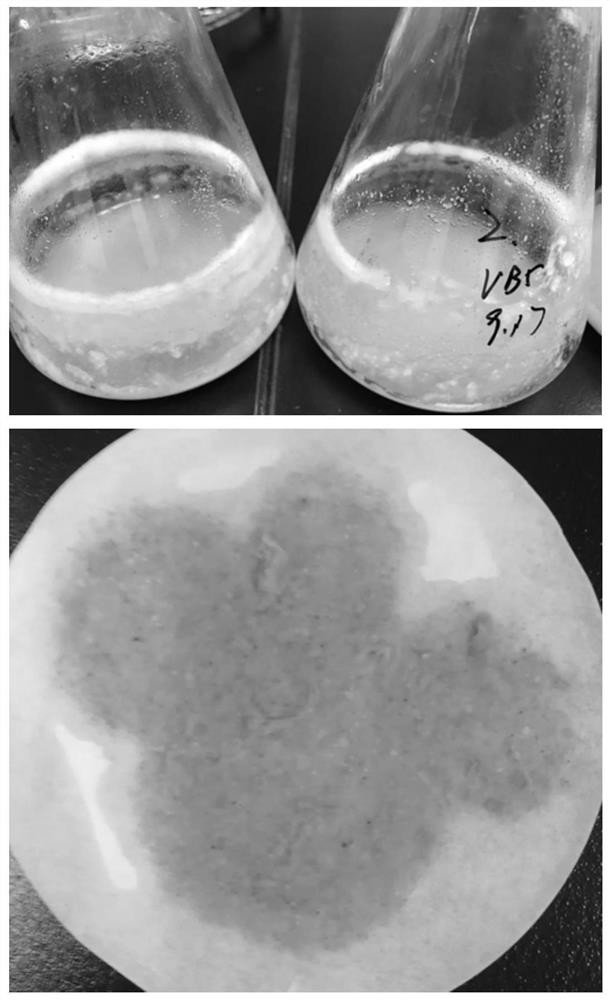

[0034] Embodiment 1: a kind of Fusarium strain and the method for producing D-pantolactone hydrolase by fermentation thereof

[0035] 1. The source of strains

[0036] Fusarium sp. CH1701 was the original strain isolated from the soil of a sugarcane orchard in Huangshan City, Anhui Province. + ion beam implantation mutagenesis selection. After the strain was cultured in PDA slant medium at 28±1℃ for 2-4 days, the aerial mycelium was scraped off with a sterile inoculating loop, and the mycelium was broken by shaking in a test tube containing deionized water and glass beads , to prepare mycelium suspension, N + The specific steps of ion beam implantation mutagenesis are as follows:

[0037] (1) The mycelium suspension of the above-mentioned starting strain Fusarium sp. CH1701 was appropriately diluted.

[0038] (2) 100 μl of mycelium diluent was evenly spread on a blank glass plate with a diameter of 90 mm with a glass coating rod, placed on an ultra-clean work surface and d...

Embodiment 2

[0059] Example 2: Method for the production of D-pantolactone hydrolase by fermentation

[0060] (1) Preparation of seed liquid in seed pots.

[0061] Put 8L of seed medium into a 10L seed tank (see Example 1 for the ratio of the seed medium, and add a defoamer 0.05%, w / v), sterilize by steam sterilization, 30min at 121°C, wait for After cooling, insert 80ml shake flask seed solution, culture temperature 28±1℃, stirring speed 200rpm, ventilation 1vvm, culture for 24-26h, pH6.5-7.5 at this time, mycelium concentration 20-30%. The strains were the same as those in Example 1.

[0062] (2) Preparation and cultivation of fermentor medium.

[0063] The formula of the fermentation medium is the same as the aforementioned Example 1, but 0.05% (w / v) of PPG should be added as a defoaming agent, the fermentation tank is 50L, the feeding volume is 40L, the pH before elimination is 7.0, and the pH after elimination is 6.7. Sterilize by steam at 121°C for 30min, after cooling, insert abo...

Embodiment 3

[0064] Example 3: Method for the production of D-pantolactone hydrolase by fermentation

[0065] Seed medium: sucrose 0.5%, soluble starch 0.5%, yeast extract 0.6%, gluten powder 1%, beef extract 0.3%, MgSO 4 ·7H 2 O 0.01%, NaCl 0.3%, pH 7.0-7.5 before elimination, shake flask with liquid volume of 30ml / 250ml conical flask, sterilized at 121°C for 30min. A piece of mycelium was dug from the slope of Example 1 to be inserted into the seed medium, and placed on a shaking table for 24-26 hours at 28±1°C. Then pipette 2.5ml of seed culture liquid into fermentation medium: 1% sucrose, 1% soluble starch, 1.5% gluten powder, 0.5% peanut flour, 1% yeast powder, MgSO 4 ·7H 2 O 0.005%, NaCl 0.2%, CaCl 2 0.005%, ZnSO 4 ·7H 2 O 0.0005%, FeCl 3 ·6H 2 O 0.00006%, CaCO 3 0.3%, pH 7.0-7.5 before elimination, 25ml / 250ml conical flask for fermentation medium, sterilized at 121°C for 30min, placed on a shaker at 28±1°C for 46-48h, and the enzyme activity of the fermentation broth was m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com