Analytical calculation method for magnetorheological liquid viscosity of vibration absorber at different temperatures

A technology of liquid viscosity and shock absorber, which is applied in the field of analysis and calculation of magnetorheological fluid viscosity in shock absorbers, and can solve problems such as difficult measurement of magnetorheological fluid viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

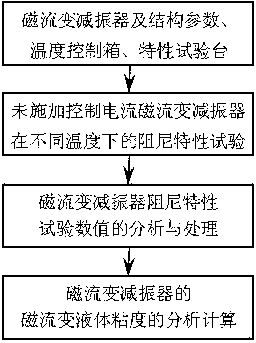

Method used

Image

Examples

Embodiment 1

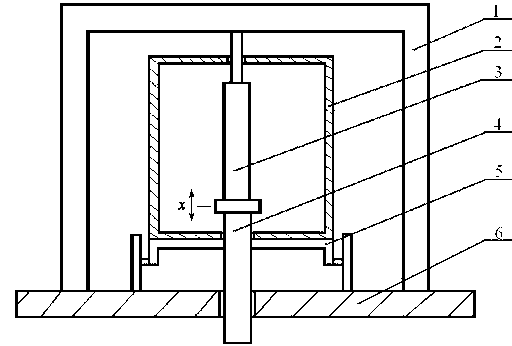

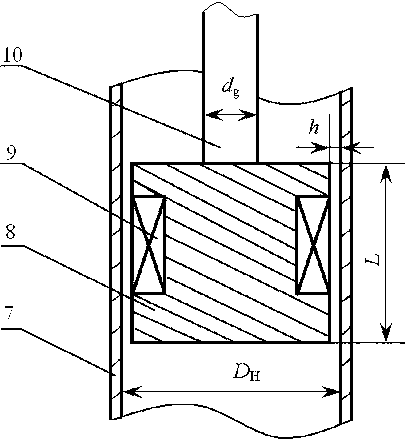

[0027] Embodiment 1: The schematic diagram of the damping characteristic test bench and the temperature control box of the shock absorber at different temperatures, such as figure 2 As shown, the bench 1 of the shock absorber test bench, the temperature control box 2, the tested shock absorber 3, the hydraulic actuator 4, the temperature control box support bracket 5, and the installation base of the shock absorber test bench, wherein, The internal temperature of the temperature control box 2 is controlled by liquid nitrogen or a heater and a computer to maintain the set temperature of the temperature control box 2; the actuator 4 is controlled by a certain amplitude A and frequency through the MTS controller and hydraulic servo system. f Harmonic displacement of x Get some exercise. The displacement of the shock absorber is measured by displacement and force sensors x i and the corresponding damping force F d . Schematic diagram of the piston, cylinder and piston of a ...

Embodiment 2

[0039] Embodiment 2: The structural parameters of a magnetorheological shock absorber and the magnetorheological fluid used are exactly the same as those of Embodiment 1, except that the temperature of the temperature control box controlled during the test T =0°. Maximum test speed for magnetorheological shock absorbers V max =1.0m / s, at control current I = 0A, carry out the damping characteristic test of the magnetorheological shock absorber, and analyze and calculate the viscosity of the magnetorheological fluid in the case of the shock absorber at 0° mu 0 .

[0040] Adopt the technical scheme implementation step of embodiment one, the viscosity of the magnetorheological fluid under 0 ° situation to this shock absorber mu 0 Perform analytical calculations, namely:

[0041] (1) temperature T The damping characteristic test of the lower magneto-rheological shock absorber without applying control current:

[0042] Because the maximum speed of shock absorber test test i...

Embodiment 3

[0052] Embodiment 3: The structural parameters of a magnetorheological shock absorber and the magnetorheological fluid used are exactly the same as those in Embodiment 1, except that the temperature of the temperature control box is controlled during the test T =-20°. Maximum test speed for magnetorheological shock absorbers V max =1.0m / s, at control current I = 0A, carry out the damping characteristic test of the magnetorheological shock absorber, and analyze and calculate the viscosity of the magnetorheological fluid under the temperature of the shock absorber at -20° mu 0 .

[0053] Using the implementation steps of the technical scheme of Embodiment 1, the viscosity of the magnetorheological fluid under the condition of -20° for the shock absorber mu 0 Perform analytical calculations, namely:

[0054] (1) temperature T The damping characteristic test of the lower magneto-rheological shock absorber without applying control current:

[0055] Because the maximum spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Damping force | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com