Preparation method of porous graphene

A porous graphene and graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of small pore size range of porous graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention discloses a preparation method of porous graphene, comprising:

[0021] The carbon material is heated with an activator to react to obtain porous graphene, the carbon material is graphene or modified graphene, and the activator is a transition metal or a transition metal compound.

[0022] In the process of preparing porous graphene, the present invention fully contacts the carbon material with a transition metal or transition metal compound activator, and reacts the carbon material with the transition metal or transition metal compound under heating conditions to obtain a transition metal carbide, The transition metal obtained from the decomposition of the transition metal carbide is reacted with the carbon material again, and the reaction is repeated, and finally porous graphene is obtained.

[0023] According to the present invention, the carbon material and the activator are heated to make the activator react with the carbon m...

Embodiment 1

[0035] (1) Stir 100mg graphene oxide, 100mg nickel powder and 400mL water evenly to make a slurry;

[0036] (2) Dry the above slurry in a vacuum oven at 60°C, and anneal at 600°C for 1 hour under the protection of an inert atmosphere in a tube furnace;

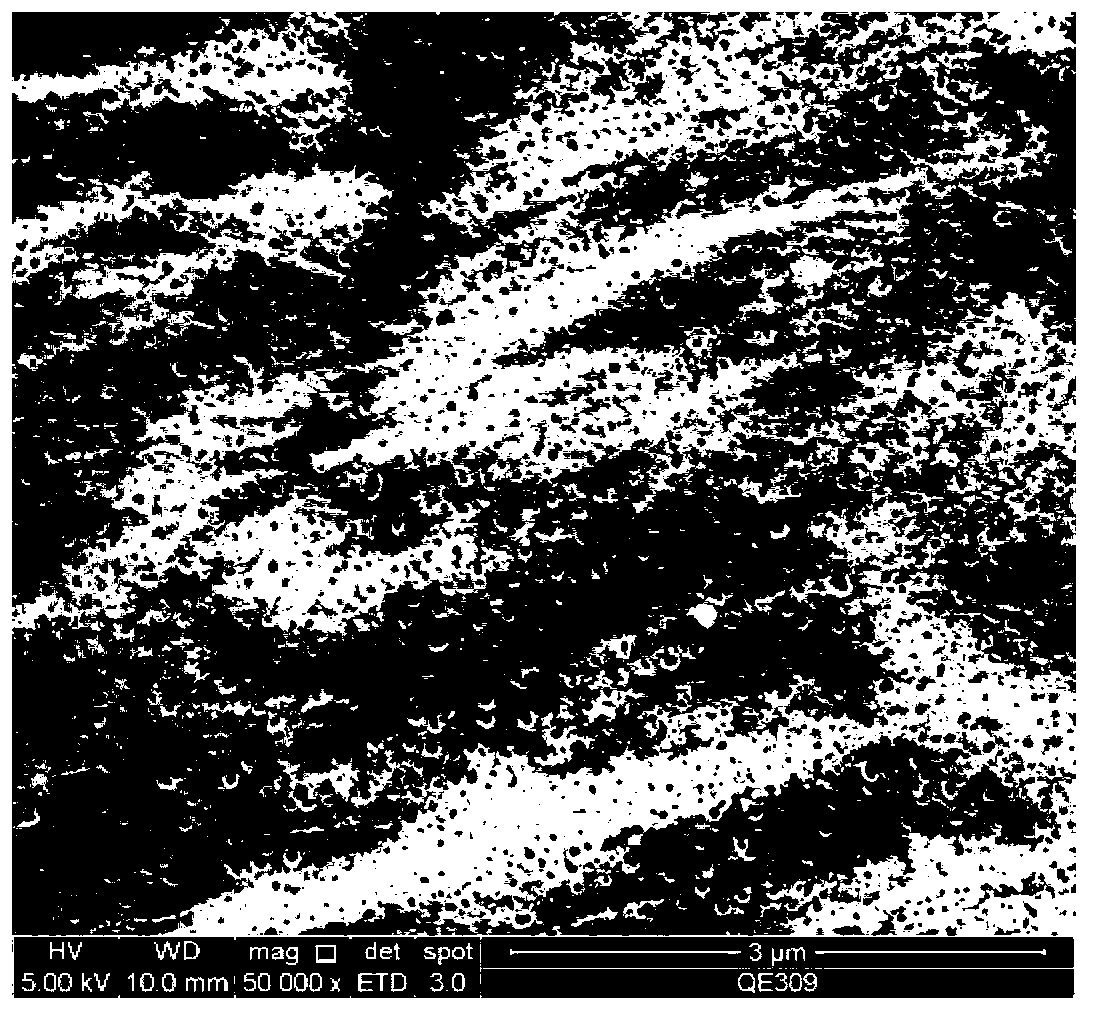

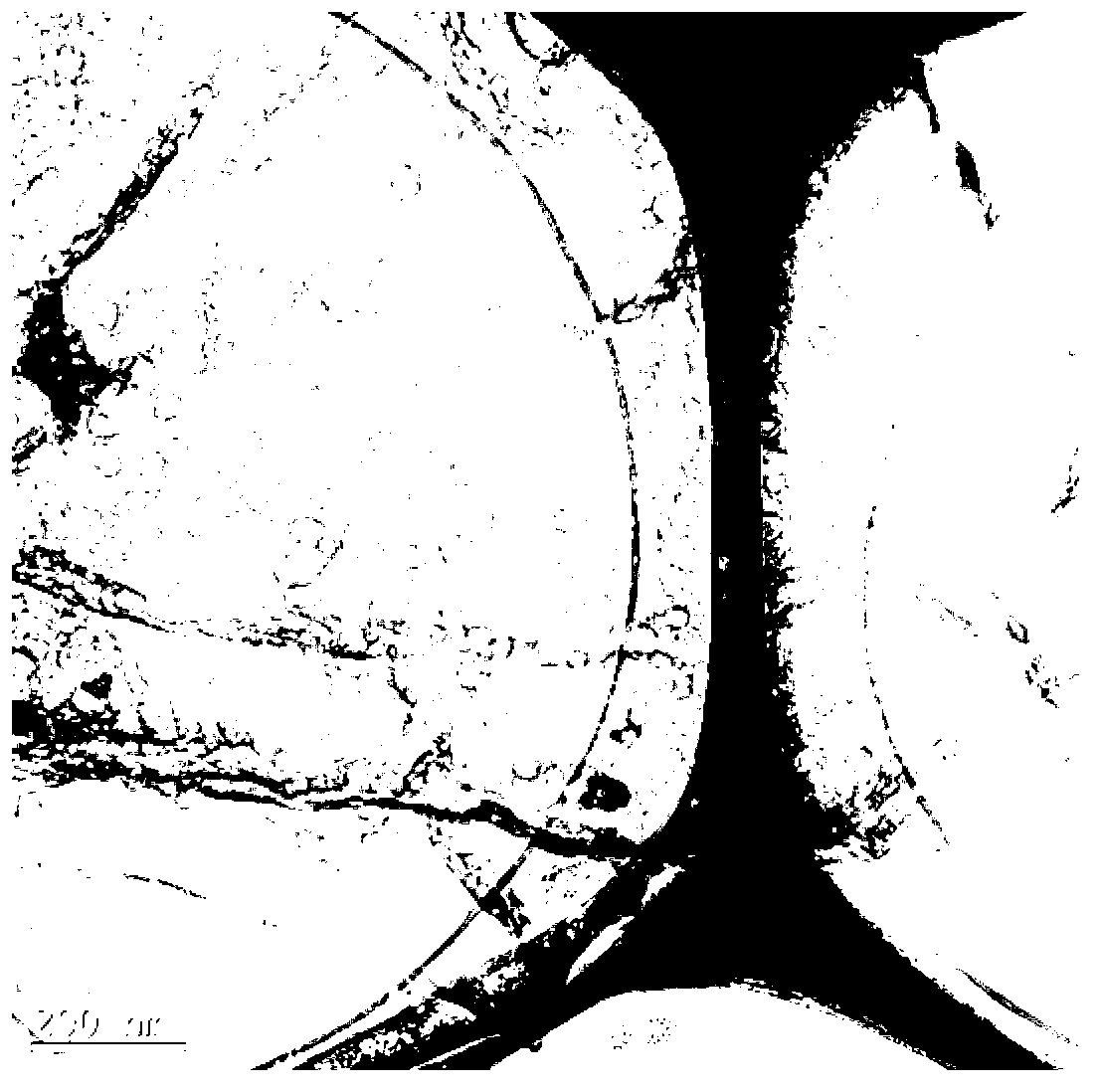

[0037] (3) After the reaction, the product was treated in dilute hydrochloric acid, washed and dried to obtain porous graphene. figure 1 The scanning electron micrograph of the porous graphene prepared for the present embodiment, figure 2 Transmission electron micrograph of porous graphene, by figure 1 and figure 2 It can be seen that there are uniform pores distributed on the surface of the graphene, and the diameter of the porous graphene is about 20 nm.

Embodiment 2

[0039] (1) Stir 100mg graphene oxide, 200mg iron oxide and 300mL water evenly to make a slurry;

[0040] (2) Dry the above slurry in a vacuum oven at 60°C, and anneal at 700°C for 2 hours under the protection of an inert atmosphere in a tube furnace;

[0041] (3) After the reaction, the product was treated in dilute hydrochloric acid, washed and dried to obtain porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com