Preparation method of ULPA ultra performance air filter material

An air filter material and ultra-high-efficiency technology, applied in the direction of filtration separation, separation method, pulp beating method, etc., can solve the problems of porosity, low efficiency of dust holding capacity, etc., achieve low resistance, high dust holding capacity, and increase the effect of effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step: the preparation method of ultrafine glass fiber

[0026] Superfine glass fibers are produced according to the prior art.

[0027] In the second step, 20% by weight of glass fibers with an average diameter of 0.3 μm, 30% by weight of glass fibers with an average diameter of 0.4 μm, 20% by weight of glass fibers with an average diameter of 9 μm, and 30% by weight of glass fibers with an average diameter of 17 μm long glass fibers (length 8-10mm) were beaten and dispersed in an aqueous solution with sulfuric acid, and the mass concentration of the slurry was controlled to be 5%. The acidity of the slurry was controlled to be pH 2.5 with sulfuric acid, and the beating time was 45 minutes.

[0028] The third step is adding the obtained slurry into a slurry tank to dilute to a mass concentration of 0.5%, adjusting the pH to 3.5, and storing it for 60 minutes under this condition to redisperse the slurry.

[0029] The fourth step is to remove the slag from the...

Embodiment 2

[0033] The first step: the preparation method of ultrafine glass fiber

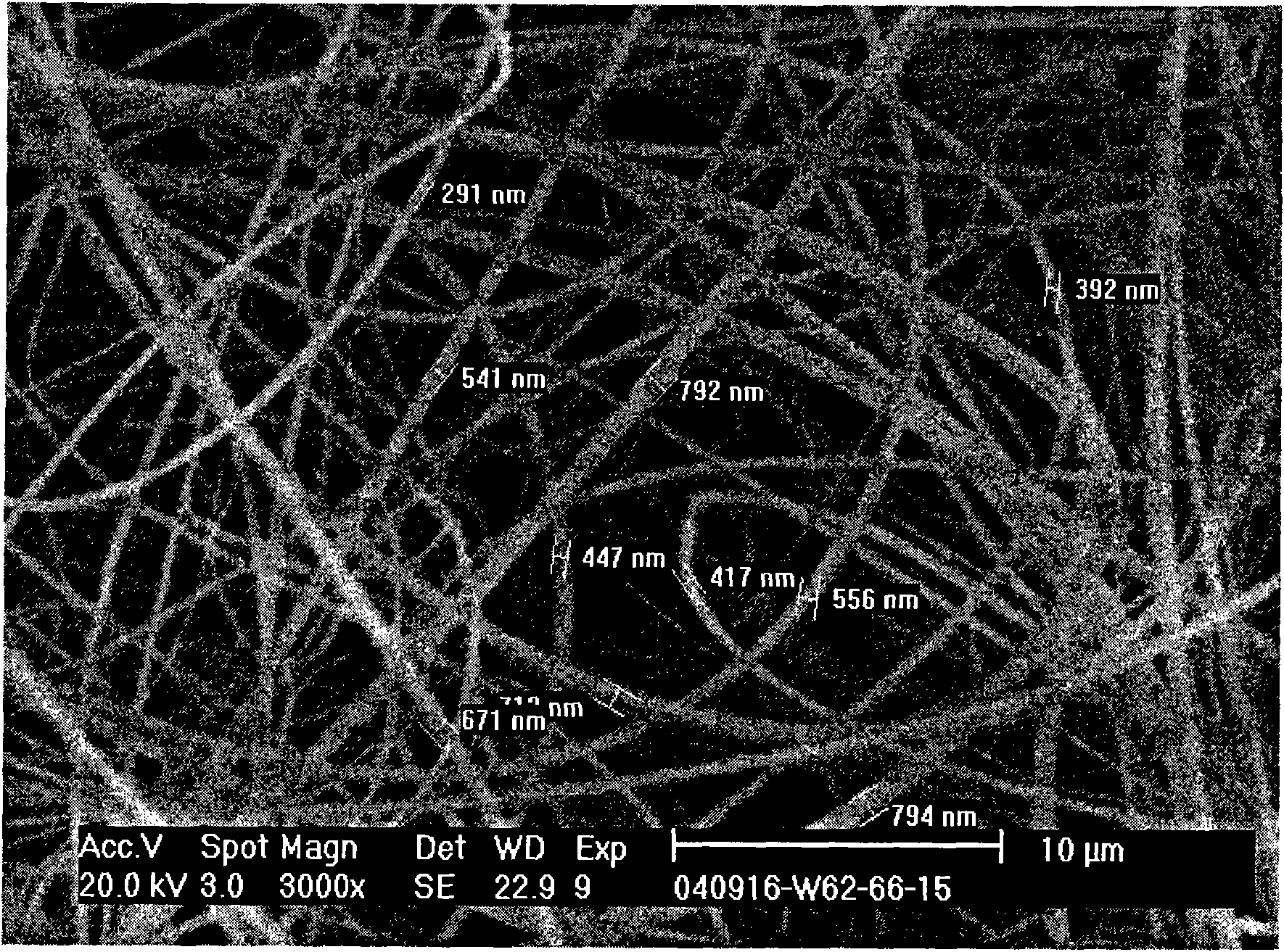

[0034] Using self-made fiber glass block, the composition of the fiber glass block and its weight / number ratio are: SiO 2 48 copies, Al 2 o 3 10 copies, B 2 o 3 16 parts, Na 2 O 13 parts, K 2 1 part of O, 0.3 parts of CaO, 0.2 parts of MgO, 8 parts of BaO, and 3.5 parts of ZnO. The fiber glass block is heated to 950°C and melted in the furnace, and the wire is drawn through the arrangement of leakage holes with a diameter of 1mm. The drawing diameter is controlled at 10μm, and the drawing speed is 2.5m / min. The jetted flame makes the glass filaments into glass fibers below 0.3μm, the nozzle width of the combustion chamber is 6mm, and the jet air velocity is 600m / s to obtain micro glass fibers, see figure 1 .

[0035]In the second step, 29% by weight of glass fibers with an average diameter of 0.2 μm, 28% by weight of glass fibers with an average diameter of 0.6 μm, 15% by weight of glass fibers...

Embodiment 3

[0041] The preparation method is the same as in Example 2, and the composition of the mixed glass fibers is: 25% by weight of glass fibers with an average diameter of 0.3 μm, 35% by weight of glass fibers with an average diameter of 0.8 μm, and 18% by weight of glass fibers with an average diameter of 9 μm Fiber and 22% by weight of glass long fibers (8-10 mm in length) with an average diameter of 22 μm.

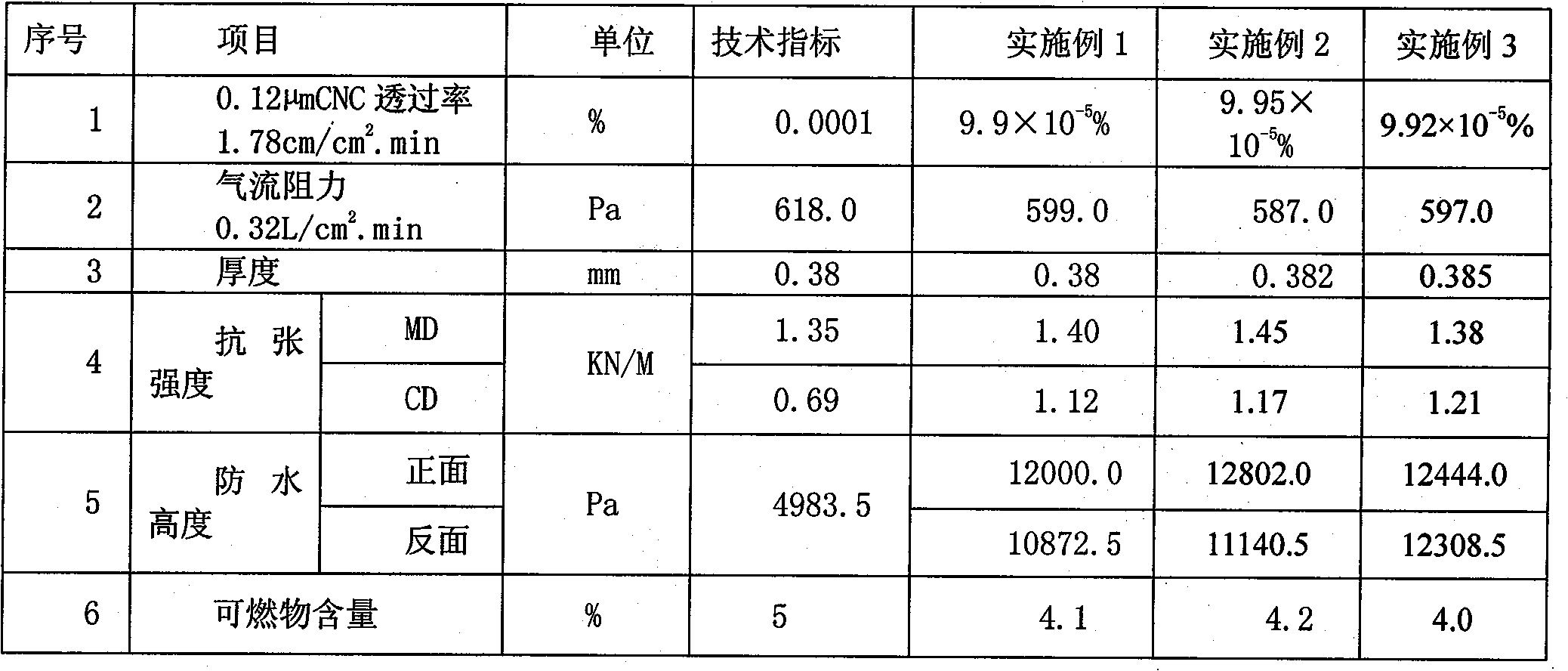

[0042] The resulting filter material was inspected. The technical indicators, inspection conditions and test methods are carried out according to the requirements stipulated in the current foreign Class 5000ULPA filter material technical conditions. The results can be seen in Table 1 and Table 2.

[0043] Table 1: The piece performance of filter material of the present invention

[0044]

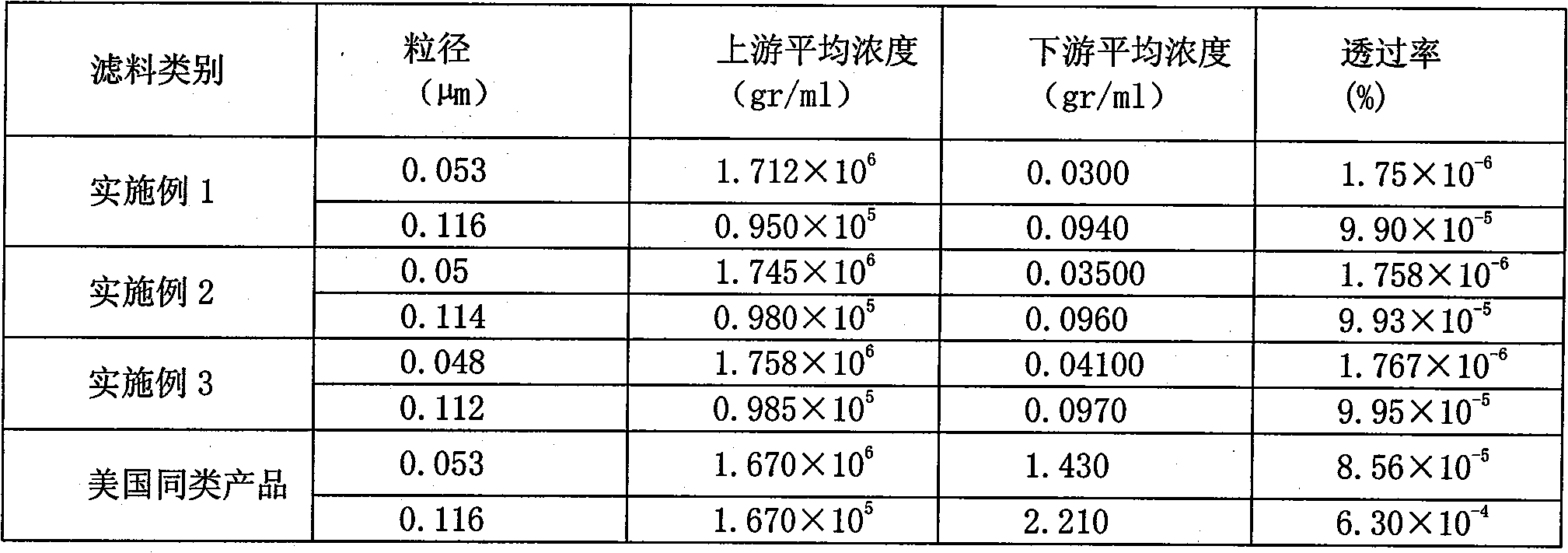

[0045] Table 2: The permeability of filter material of the present invention and other filter materials

[0046]

[0047] It can be seen that the various performances of the air fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com