Rotary trimming and chamfering device capable of being used obversely and reversely

A chamfering device and a flip-up technology, applied in the field of non-standard tools, can solve the problems of easy damage, finishing plane, inconvenient manual operation of polishing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

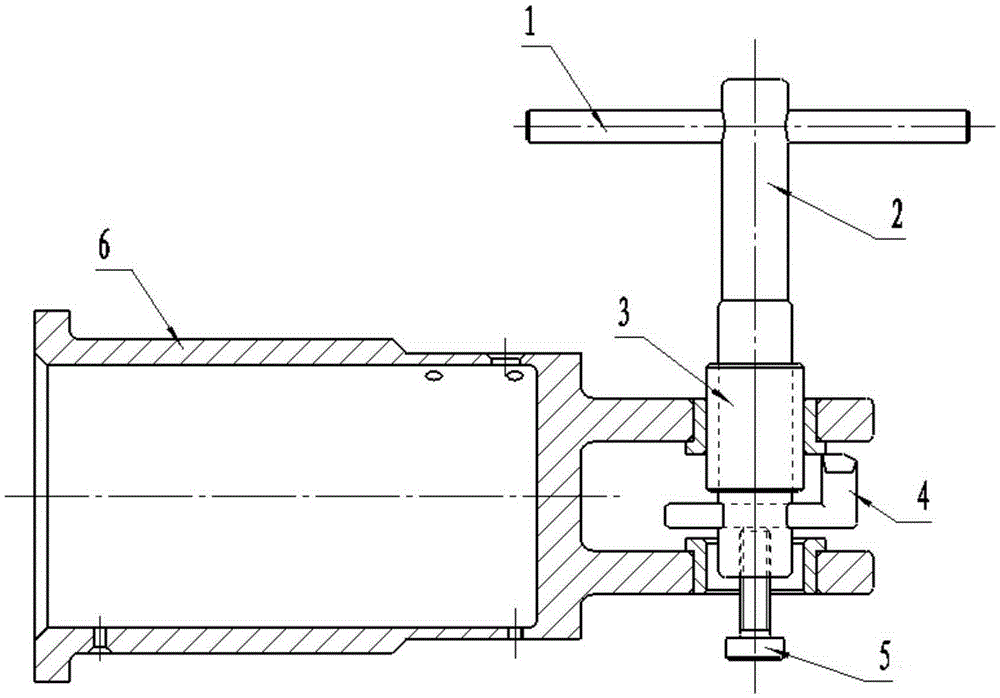

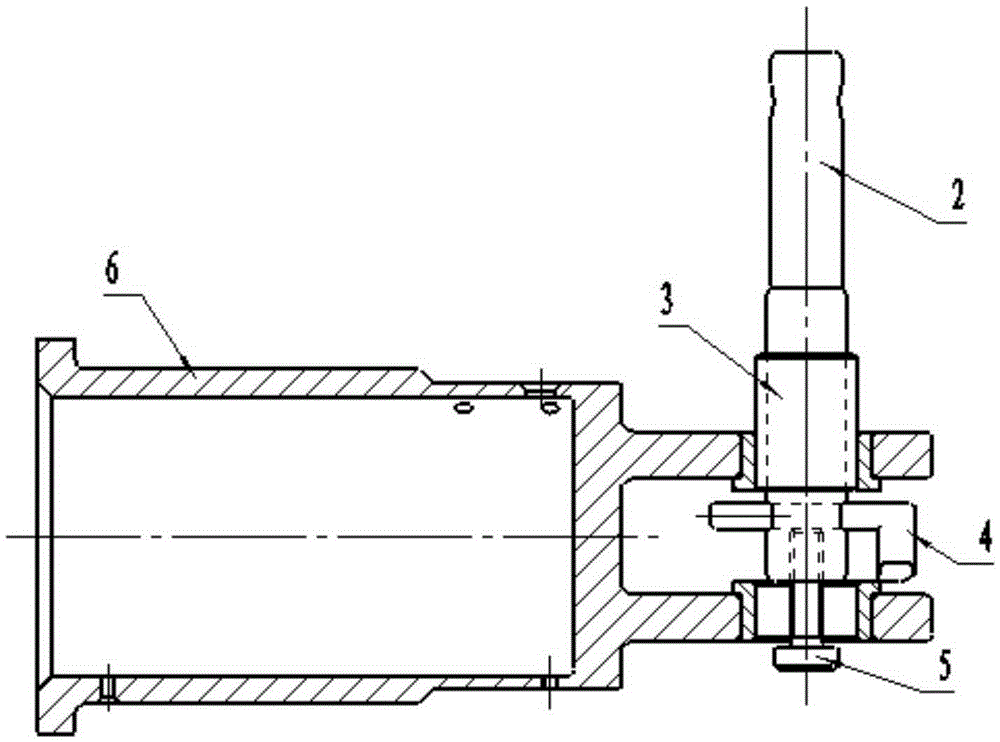

[0013] exist figure 1 , figure 2 Among them, the reversible positive and negative dual-purpose trimming and chamfering device includes: tool bar guide body 2, L-shaped cutting tool 4 and guide hole bushing 3 for the tool bar guide body 2, wherein: the front end of the tool bar guide body 2 is an insert The hole guide body, the L-shaped cutting tool 4 with chamfered blades on both sides of the cutter head can adjust the length and radially pass through the radial through hole of the hole guide body. After the L-shaped cutting tool edge is turned downward or upward, the The locking screw 5 is axially locked and fixed. According to the size of the inner hole of the bushing or bearing, the corresponding tool bar guide body 2 can be selected. In order to avoid scratching the inner hole, the gap between the tool bar guide body and the inner hole of the product part 6 is generally selected as 0.15-0.3mm. If there is no corresponding Specifications of the tool bar guide body, can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com