Bone tissue engineering bracket material and preparation method and application thereof

A technology for bone tissue engineering and scaffold materials, which is applied in scaffolds, medical science, prostheses, etc., and can solve the problems of low porosity and poor pore connectivity of scaffolds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The method for preparing bone tissue engineering scaffold material provided by the present invention includes the steps of: mixing calcium phosphate dual-phase powder with a medically acceptable binder, then mixing with paraffin microspheres and calcining to obtain bone tissue engineering provided by the present invention Scaffolds.

[0038] In the preparation method provided by the present invention, the porosity of the scaffold material obtained can be adjusted according to the different mass ratios of the added paraffin microspheres and calcium phosphate dual-phase powder, and the paraffin microspheres and calcium phosphate dual-phase powder The mass ratio of phase powder is 5:1-9:1; preferably 5.5:1-7.5:1. As the amount of paraffin microspheres increases, the porosity of the porous scaffold material increases accordingly. If the amount of paraffin microspheres added is too low, the scaffold material obtained after calcination has almost no through holes; and after ...

Embodiment 1

[0058] Scaffold material for bone tissue engineering I

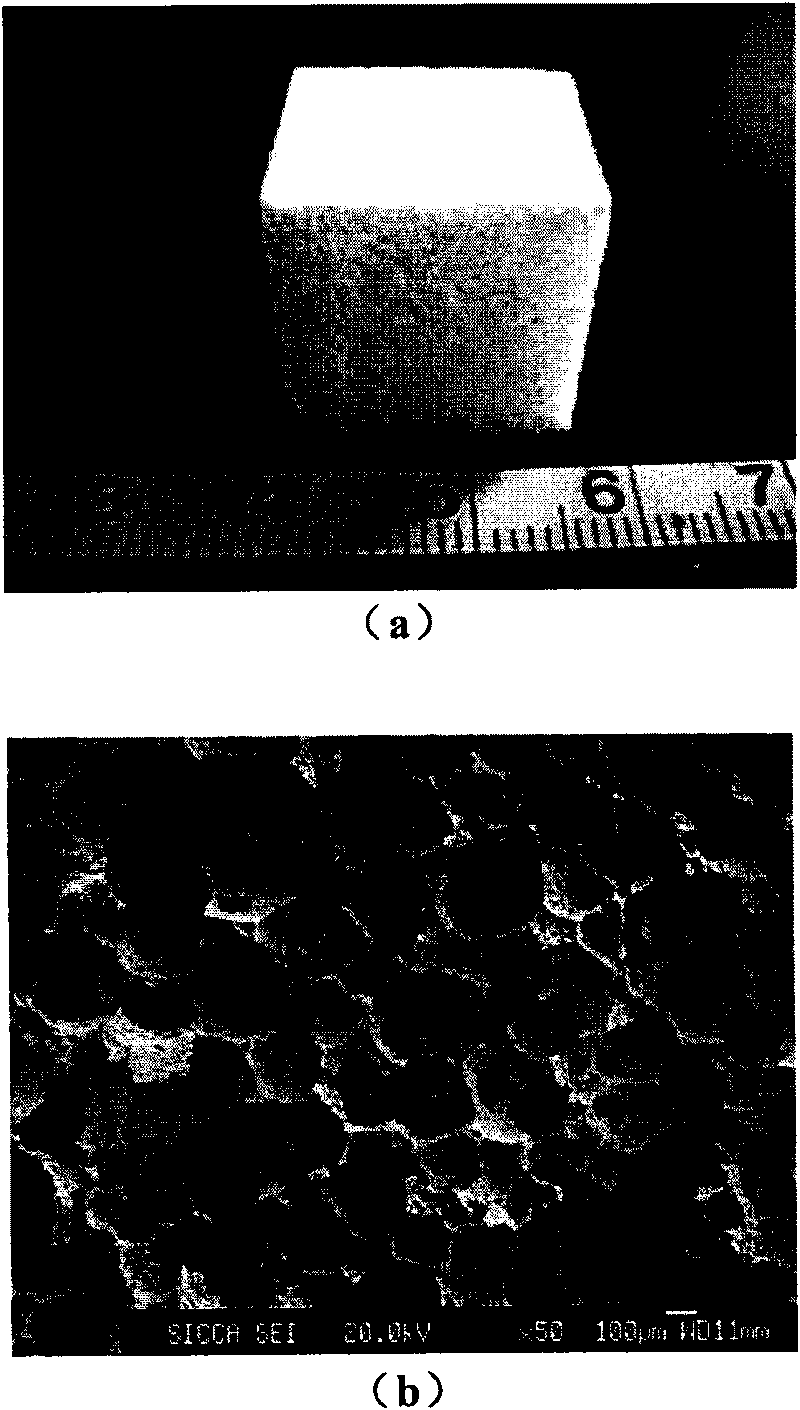

[0059] Mix 1g of calcium phosphate biphasic powder (the molar ratio of HAP and TCP is 2:1) with 0.3g of silica sol (concentration: 15w / v%, purchased from Qingdao Ocean Chemical Co., Ltd.), and then add a particle size of 300- 6 g of 500 μm paraffin microspheres (paraffin was purchased from Shanghai Huayong Paraffin Co., Ltd., the microspheres were self-made), mixed evenly, and then statically pressed to obtain a ceramic body. Dry at room temperature for 2 days, dry in an oven at 37°C for 4 days, and place in a muffle furnace for calcination. Raise the temperature up to 200°C at a rate of 1°C / min, keep it warm for 1 hour, then raise the temperature up to 1100°C at a rate of 2°C / min and keep it warm for 3 hours, then cool down to room temperature with the furnace to obtain bone tissue engineering scaffold material I. Gross and scanning electron microscope (SEM) images of the ceramics are shown in figure 1 middle.

[006...

Embodiment 2

[0062] Scaffold Materials for Bone Tissue Engineering II

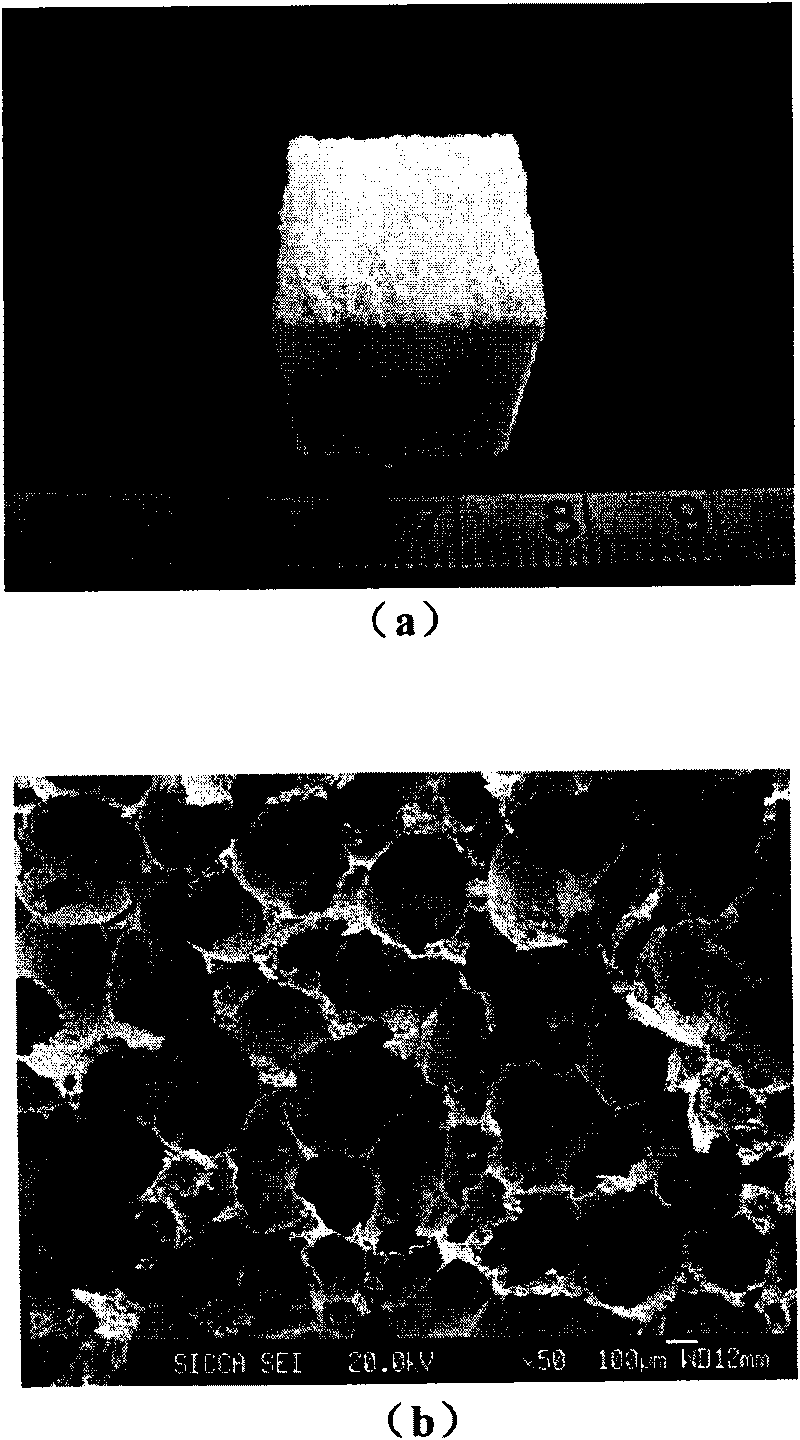

[0063] Mix 1g of calcium phosphate powder (the molar ratio of HAP and TCP is 1:3) with 0.6g of silica sol (concentration: 20w / v%, purchased from Qingdao Ocean Chemical Co., Ltd.), and then add 150-300μm and 300 - 3 g of 500 μm paraffin microspheres (paraffin was purchased from Shanghai Huayong Paraffin Wax Co., Ltd., and the microspheres were self-made), mixed evenly, and then statically pressed. Dry at room temperature for 1 day, dry in an oven at 37°C for 4 days, and place in a muffle furnace for calcination. Raise the temperature to 150°C at a rate of 0.5°C / min, hold for 2 hours, then raise the rate of 2°C / min to 1050°C and hold for 3 hours, and cool to room temperature with the furnace to obtain porous biphasic calcium phosphate ceramics. Gross and SEM photographs of the ceramics are shown in figure 2 middle.

[0064] The results show that the pore diameter range of the scaffold material is 250-450 μm, the conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com