A method for processing small holes in carbon fiber composite materials by ring pulse laser

A pulsed laser, composite material technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of non-penetration, thermal influence, tool wear, etc., to achieve the effect of increasing the aperture range and avoiding burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

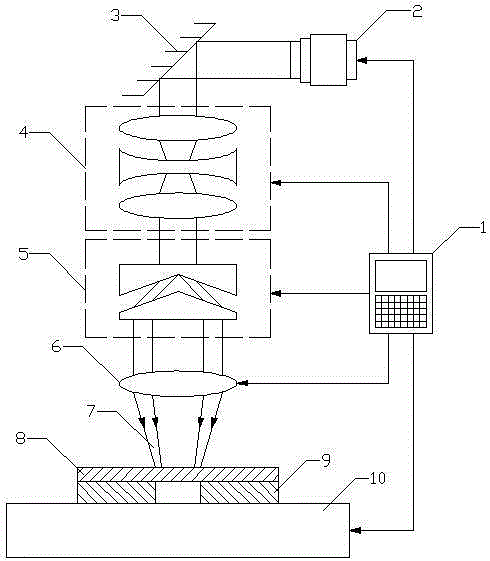

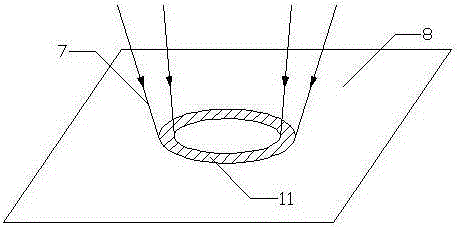

[0018] The carbon fiber volume fraction in the carbon fiber composite material is 50%: the backing plate 9 is fixed on the CNC workbench 10, the carbon fiber composite material 8 is fixed on the upper end surface of the backing plate 9, and the center of the ring pulse laser 7 is controlled by moving the control CNC workbench 10, The hole center of the carbon fiber composite material 8 and the hole center of the backing plate 9 are on the same axis, and the size of the hole on the backing plate 9 is 12 mm; the laser 2 is turned on, and the pulsed laser passes through the reflector 3, the optical shaping system 4, the ring beam generation system 5, After the focusing lens 6 acts on the surface of the composite material, the computer control system 1 adjusts the pulse width, energy, frequency and other parameters of the ring pulse laser 7 according to the characteristics of the carbon fiber composite material 8. The pulse width is 20ns, the energy is 5J, and the frequency is 5Hz. ...

Embodiment 2

[0020] The carbon fiber volume fraction in the carbon fiber composite material is 60%: the backing plate 9 is fixed on the CNC workbench 10, the carbon fiber composite material 8 is fixed on the upper end surface of the backing plate 9, and the center of the ring pulse laser 7 is controlled by moving the control CNC workbench 10, The hole center of the carbon fiber composite material 8 and the hole center of the backing plate 9 are on the same axis, and the size of the hole on the backing plate 9 is 12 mm; the laser 2 is turned on, and the pulsed laser passes through the reflector 3, the optical shaping system 4, the ring beam generation system 5, After the focusing lens 6 acts on the surface of the composite material, the computer control system 1 adjusts the pulse width, energy, frequency and other parameters of the ring pulse laser 7 according to the characteristics of the carbon fiber composite material 8. The pulse width is 10 ns, the energy is 10 J, and the frequency is 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com