Preparation method of permanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber nanofiltration membrane

A technology of polytetrafluoroethylene and polytetrafluoroethylene, which is applied in the field of preparation of permanent hydrophilic nano-graphene polytetrafluoroethylene hollow fiber nanofiltration membrane, can solve the problems of complex preparation process and complex structure of nanofiltration membrane. Achieve the effect of simple preparation process, improve adsorption and filtration efficiency, and improve binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

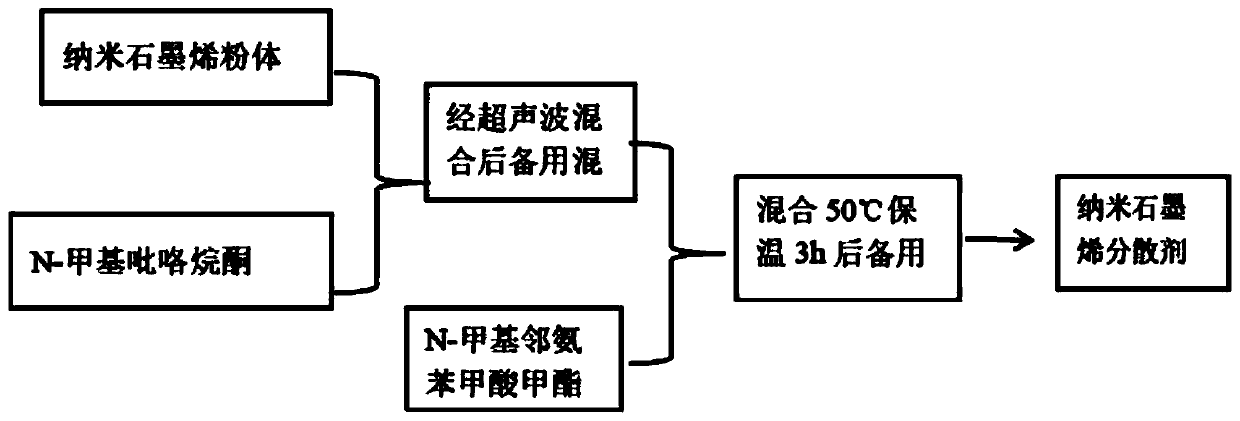

[0034] (1) Preparation of nano-graphene dispersant: such as figure 1 As shown, take 15g nano-graphene powder (commercially available product, purity: >99.5wt%, thickness: 4-20nm, number of layers: <30, diameter: 5-10μm), and disperse it into 10mL N-methylpyrrolidone , after ultrasonic vibration for 2 hours to obtain a graphene dispersion, add 80wt% N-methylpyrrolidone aqueous solution, dilute to 30mL, add 0.026mg N-methyl anthranilate methyl ester, keep warm at 50°C for 3 hours, cool at room temperature for later use ;

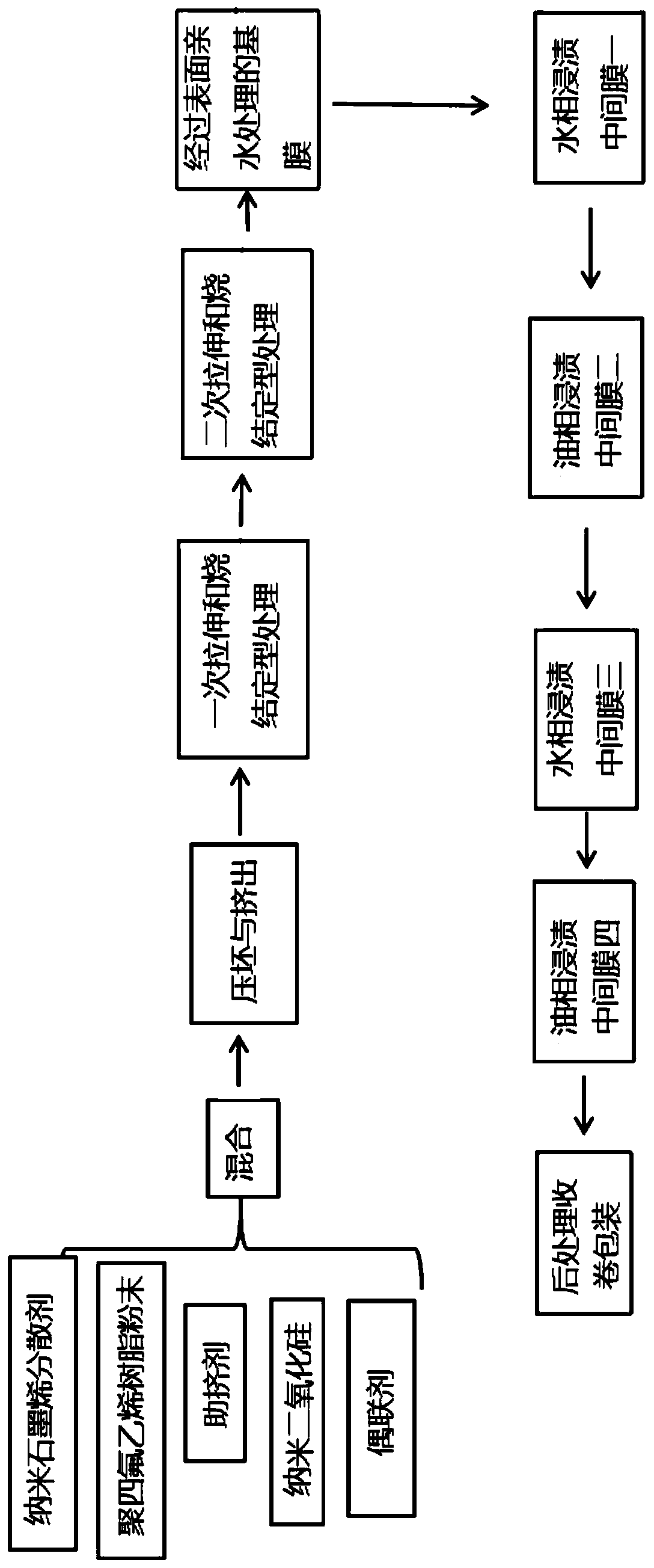

[0035] (2) Mixing: such as figure 2 As shown, F106 polytetrafluoroethylene dispersion resin powder (Dakin Corporation, Japan, molecular weight 2-10 million), liquid paraffin, nano-silica (commercially available product, average particle size 10-30nm), nano-graphene dispersion agent, KH550 coupling agent according to the mass ratio of 38:6:4:3.5:0.05 mixed evenly, at 20 ℃ for 30 hours to make F106 polytetrafluoroethylene dispersed resin powder, liquid paraff...

Embodiment 2

[0046] (1) Preparation of nano-graphene dispersant; take 10g of nano-graphene powder (commercially available product, purity: >99.5wt%, thickness: 4-20nm, number of layers: <30, diameter: 5-10μm), and Disperse it in 10mL N-methylpyrrolidone, and obtain a graphene dispersion after ultrasonic vibration for 2h, add 80wt% N-methylpyrrolidone aqueous solution, dilute to 30mL, add 0.026mg N-methyl anthranilate methyl ester , 50°C for 3 hours, then cooled at room temperature for later use.

[0047] (2) Mixing: F106 polytetrafluoroethylene dispersion resin powder (Dakin Corporation, Japan, molecular weight 2-10 million), petroleum ether and nano-silica (commercially available products, average particle size 10-30nm), nano Graphene dispersant and titanate silane coupling agent CT-114 are mixed evenly at a mass ratio of 50:8:5:4:0.08, and left to stand at 40°C for 20 hours to make polytetrafluoroethylene dispersion resin powder, petroleum ether , nano-silica, nano-graphene dispersant, ...

Embodiment 3

[0058] (1) Preparation of nano-graphene dispersant; take 8g of nano-graphene powder (commercially available product, purity: >99.5wt%, thickness: 4-20nm, number of layers: <30, diameter: 5-10μm), and Disperse in 10mL of N-methylpyrrolidone, ultrasonically shake for 2h to prepare a graphene dispersion, add 80wt% aqueous solution of N-methylpyrrolidone, dilute to 30mL, add 0.026mg of methyl N-methylanthranilate, 50°C After 3 hours of heat preservation, cool at room temperature for later use;

[0059] (2) Mixing: F106 polytetrafluoroethylene dispersed resin powder (Dakin Corporation of Japan, molecular weight 2 to 10 million), kerosene and nano silicon dioxide (commercially available products, average particle size 10-30nm), nano graphite Mix ethylene dispersant and KH792 silane coupling agent according to the mass ratio of 20:15:10:2:5, and let it stand for 25 hours at 30°C to make polytetrafluoroethylene dispersion resin powder, kerosene, nano-silica, nano Graphene dispersant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com