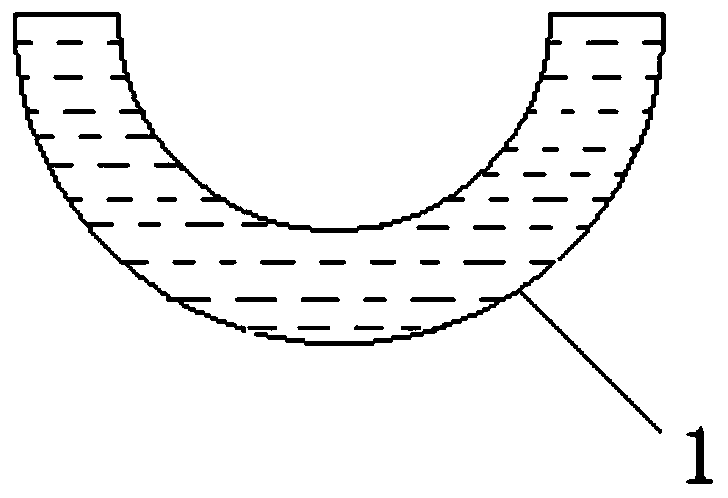

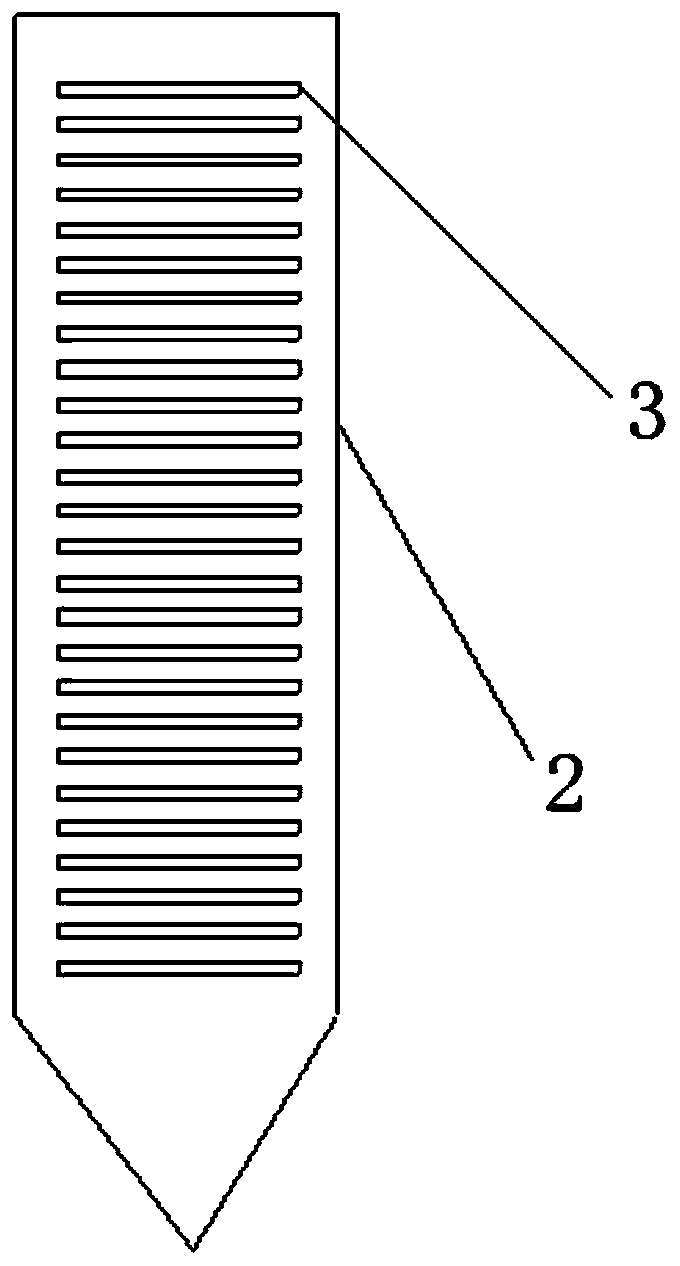

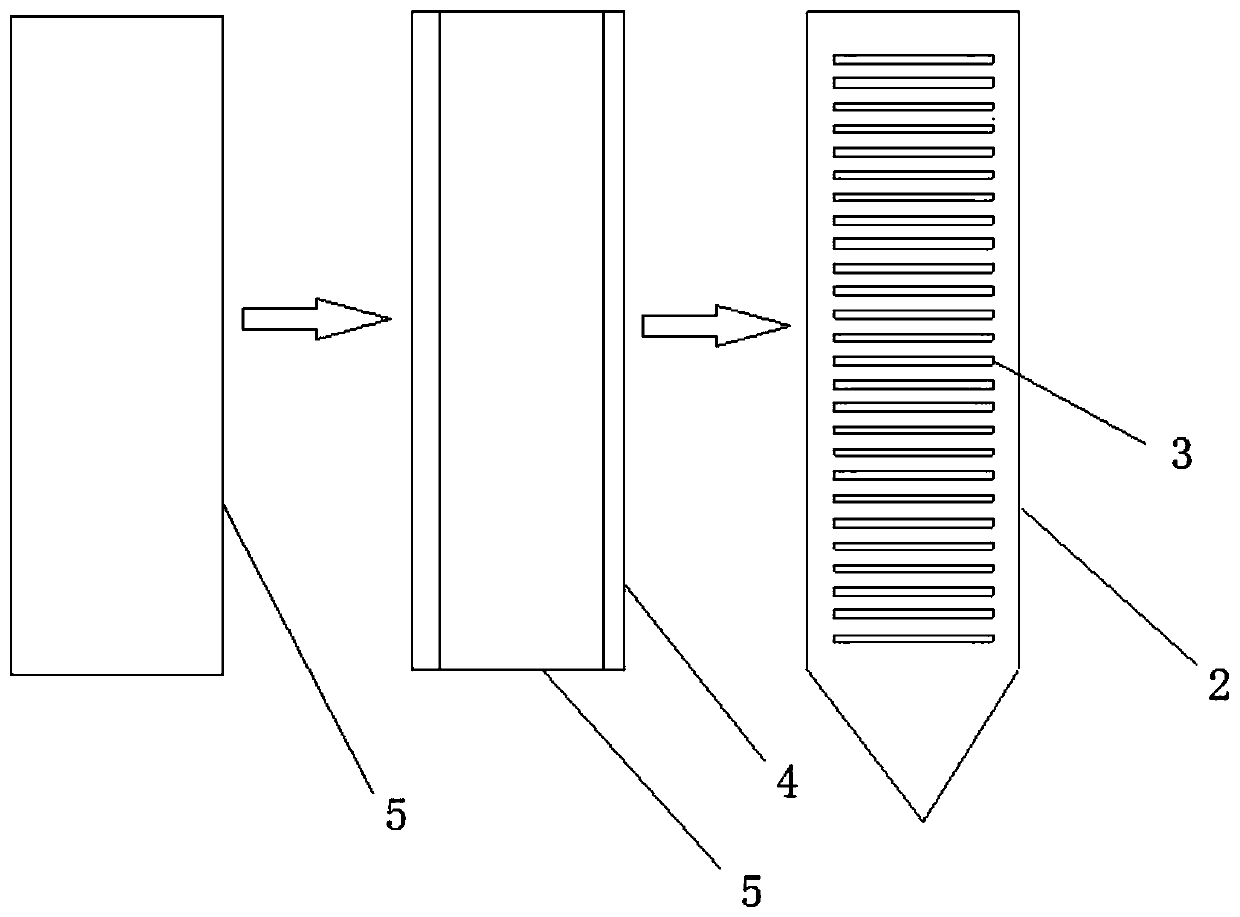

Method and sampling device for separating and purifying water body micro-organism strains

A technology of microbial strains and collection devices, which is applied in biochemical equipment and methods, biological material sampling methods, and separation of microorganisms. problems, to achieve the effect of easy removal, not easy to decline microbial metabolic function, and small footprint of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1, the NH of 1.0g / L 4 Cl, 0.3g / L of K 2 HPO 4 , 0.3g / L of KH 2 PO 4 , 0.1g / L KCl, 0.1g / L CaCl 2 2H 2 The NaCl of 0,30g / L, the yeast extract of 0.1g / L, the cysteine of 0.5g / L, the sodium thiosulfate of 3.16g / L and 1ml trace element nutrient solution are mixed to obtain the culture medium solution of 1L, Wherein the trace element nutrient solution contains copper, manganese, zinc, iron, magnesium, molybdenum and boron, and the culture medium solution is adjusted to pH 7.6 with 10M KOH solution. In terms of the percentage of volume in milliliters, add 0.5% agar powder, heat and dissolve to prepare a solution;

[0057] Step 2, uniformly disperse polyvinyl alcohol fibers with a length of 10 mm in 5% NaOH solution, stir at 50° C. for 12 hours, collect the fibers and dry them;

[0058] Step 3, according to the ratio of the quality of the modified polyvinyl alcohol fiber silk to the mass of the BM solid medium solution, uniformly mix 1% of the modified polyvinyl a...

Embodiment 2

[0068] Step 1, the NH of 1.0g / L 4 Cl, 0.3g / L of K 2 HPO 4 , 0.3g / L of KH 2 PO 4 , 0.1g / L KCl, 0.1g / L CaCl 2 2H 2 The NaCl of 0,30g / L, the yeast extract of 0.1g / L, the cysteine of 0.5g / L, the sodium thiosulfate of 3.16g / L and 1ml trace element nutrient solution are mixed to obtain the culture medium solution of 1L, Wherein the trace element nutrient solution contains copper, manganese, zinc, iron, magnesium, molybdenum and boron, and the culture medium solution is adjusted to be 7 with the KOH solution of 10M, and the culture medium solution after adjusting the pH according to the mass grams of agar powder In terms of the percentage of volume in milliliters, add 0.5% agar powder, heat and dissolve to prepare a solution;

[0069] Step 2, uniformly disperse polyvinyl alcohol fibers with a length of 5 mm in 5% NaOH solution, stir at 60° C. for 8 hours, collect the fibers and dry them;

[0070] Step 3, according to the ratio of the quality of the modified polyvinyl alcohol...

Embodiment 3

[0080] Step 1, the NH of 1.0g / L 4 Cl, 0.3g / L of K 2 HPO 4 , 0.3g / L of KH 2 PO 4 , 0.1g / L KCl, 0.1g / L CaCl 2 2H 2 The NaCl of 0,30g / L, the yeast extract of 0.1g / L, the cysteine of 0.5g / L, the sodium thiosulfate of 3.16g / L and 1ml trace element nutrient solution are mixed to obtain the culture medium solution of 1L, Wherein the trace element nutrient solution contains copper, manganese, zinc, iron, magnesium, molybdenum and boron, and the KOH solution of 10M is used to adjust the culture medium solution to a pH of 7.3, and the culture medium solution after adjusting the pH according to the mass grams of agar powder In terms of the percentage of volume in milliliters, add 0.5% agar powder, heat and dissolve to prepare a solution;

[0081] Step 2, uniformly dispersing polyvinyl alcohol fibers with a length of 8mm in 5% NaOH solution, stirring at 55°C for 10h, collecting the fibers and drying them;

[0082] Step 3, according to the ratio of the quality of the modified poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com